A free import export trade leads B2B marketplace since 1996 for manufacturers, suppliers, exporters, importers, buyers, sellers, wholesalers, freight forwarders, shippers, trade shows, exhibits, and export management.

Hello visitor from USA - 29 visiting from

USA - 29 visiting from  18 USA

18 USA  3 France

3 France  2 Germany

2 Germany  1 Zimbabwe

1 Zimbabwe  1 Hong Kong

1 Hong Kong  1 India

1 India  1 Palestine

1 Palestine  1 Brazil

1 Brazil  1 Ukraine

1 Ukraine

Hello visitor from

Auto Parts Mould

Posted at: Offers to Sell and Export | Posted on: Saturday 7 September 2019 3:20 am | Poster last visit: Thursday 19 September 2019 |

Product Category: Main

» Industrial Manufacturing and Processing Machinery and Accessories

» Industrial process machinery and equipment and supplies

» Rubber and plastic processing machinery and equipment and supplies

» Plastic injection molds

» Auto Parts Mould

Product Description:

Auto Parts Mould Features

Injection molding and pressure molding are the main methods. When designing

the flow channel and parting surface, the cavity pressure should be as small as possible, the exhaust should be smooth, the discharge position, shape, and material flow direction should be fully considered, especially some small ribs. To do the active exhaust, there must be a overflow trough. Vacuuming structure, the mold temperature balance is consistent. The appearance and electrical performance of the product are guaranteed. It solves the problems of lightweight, leakage safety and aging of automobiles, reduces costs and improves product quality.

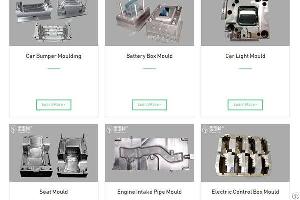

Auto parts mould mainly include car bumper molds, battery box molds, lamp molds, seat molds, engine intake pipe molds, electric control box molds and so on.

We sheet molding compound manufacturers have complete processing and testing capabilities as well as ISO14001:2004 and ISO9001-2008 management system. With our fast delivery, perfect after-sale service and stable quality, Zhejiang Aobang series plastic-sealed DC motor molds and products can be your best choice for your concern.

Company Contact:

Contact Name: Coffee Li

Company Name: Zhejiang Aobang Technology Co., Ltd

Email:

Tel: +86-15657163173

Fax:

Street Address: No.62, Zhidailang,

Sha Village, Luoshe Town, Deqing,

Huzhou City, Zhengjiang, China.

Huzhou, Zhejiang 313218

China

Website: https://www.waiwaitree.com

Member name: huzhouaobang

Country: China

China

Member Since: 07 September 2019

Total Leads: 9 huzhouaobang Import Export Business Leads

Business focus: Bmc Molding, Bmc Motor

Chat:

Verify: Safe Import Export Tips

Injection molding and pressure molding are the main methods. When designing

the flow channel and parting surface, the cavity pressure should be as small as possible, the exhaust should be smooth, the discharge position, shape, and material flow direction should be fully considered, especially some small ribs. To do the active exhaust, there must be a overflow trough. Vacuuming structure, the mold temperature balance is consistent. The appearance and electrical performance of the product are guaranteed. It solves the problems of lightweight, leakage safety and aging of automobiles, reduces costs and improves product quality.

Auto parts mould mainly include car bumper molds, battery box molds, lamp molds, seat molds, engine intake pipe molds, electric control box molds and so on.

We sheet molding compound manufacturers have complete processing and testing capabilities as well as ISO14001:2004 and ISO9001-2008 management system. With our fast delivery, perfect after-sale service and stable quality, Zhejiang Aobang series plastic-sealed DC motor molds and products can be your best choice for your concern.

Company Contact:

Contact Name: Coffee Li

Company Name: Zhejiang Aobang Technology Co., Ltd

Email:

Tel: +86-15657163173

Fax:

Street Address: No.62, Zhidailang,

Sha Village, Luoshe Town, Deqing,

Huzhou City, Zhengjiang, China.

Huzhou, Zhejiang 313218

China

Website: https://www.waiwaitree.com

Member name: huzhouaobang

Country:

Member Since: 07 September 2019

Total Leads: 9 huzhouaobang Import Export Business Leads

Business focus: Bmc Molding, Bmc Motor

Chat:

Verify: Safe Import Export Tips

Similar Suppliers And Manufacturers Import Export Trade Leads

Similar Suppliers And Manufacturers Import Export Trade Leads

Auto Bumper Mould - By haiyanautomould - On Wednesday 11 May 2022 1:21 am: mould trade process

1 quote according to sample drawing and specific requirement

2 discussion mold material cavity number price runner paym....

Auto Bumper Mould - By haiyanautomould - On Wednesday 11 May 2022 1:21 am: mould trade process

1 quote according to sample drawing and specific requirement

2 discussion mold material cavity number price runner paym.... Concrete Pile Mould - By zongheng - On Saturday 13 May 2023 7:06 am: mould for fluid concrete forming but aslo a coordinating equipment for prestressing

amp #9733 advantage high level of solidity with thickened a....

Concrete Pile Mould - By zongheng - On Saturday 13 May 2023 7:06 am: mould for fluid concrete forming but aslo a coordinating equipment for prestressing

amp #9733 advantage high level of solidity with thickened a.... Cylinder Mould For Paper Machine - By tayen - On Friday 15 July 2022 3:33 am: mould for paper machine including spindles grids spokes and spacers with spokes equally spaced on the main shaft with wire racks mounted on the s....

Cylinder Mould For Paper Machine - By tayen - On Friday 15 July 2022 3:33 am: mould for paper machine including spindles grids spokes and spacers with spokes equally spaced on the main shaft with wire racks mounted on the s.... Stainless Steel cylinder Mould - By ShijiazhuangHuatao - On Saturday 11 June 2022 7:52 am: mould

1 high speed balance detection more than 700 meters

2 weight is reduced by 30% compared to ordinary cages reducing energy consumption

....

Stainless Steel cylinder Mould - By ShijiazhuangHuatao - On Saturday 11 June 2022 7:52 am: mould

1 high speed balance detection more than 700 meters

2 weight is reduced by 30% compared to ordinary cages reducing energy consumption

.... Mould Oscillation And Deflection Detection Instrument - By WuhanCenterRise - On Wednesday 7 September 2022 3:47 am: mould oscillation and deflection detection instrument

overview

the mold is a device that shapes the cast product in continuous steel casting and it....

Mould Oscillation And Deflection Detection Instrument - By WuhanCenterRise - On Wednesday 7 September 2022 3:47 am: mould oscillation and deflection detection instrument

overview

the mold is a device that shapes the cast product in continuous steel casting and it.... Mould Online Width Adjustment And Taper Measurement - By WuhanCenterRise - On Thursday 8 September 2022 2:50 am: mould online width adjustment and taper measurement

mould online width adjustment and taper measurement

overview

in order to meet the needs of producing various specifications of continuously cast p....

Mould Online Width Adjustment And Taper Measurement - By WuhanCenterRise - On Thursday 8 September 2022 2:50 am: mould online width adjustment and taper measurement

mould online width adjustment and taper measurement

overview

in order to meet the needs of producing various specifications of continuously cast p.... Mould Die Polishing Fishing Stones Bellstone Oilstone - By BtwoECOMMERCELIMITED - On Tuesday 14 June 2022 2:57 am: mould die polishing fishing stones

moldmaker stones maily has two types-edm polishing stone and ceramic super stones these polishing stones delivers ....

Mould Die Polishing Fishing Stones Bellstone Oilstone - By BtwoECOMMERCELIMITED - On Tuesday 14 June 2022 2:57 am: mould die polishing fishing stones

moldmaker stones maily has two types-edm polishing stone and ceramic super stones these polishing stones delivers .... Moc-k100 Mould Online Oscillation Monitoring System - By WuhanCenterRise - On Friday 9 September 2022 1:51 am: mould online oscillation monitoring system

overview

mold is the casting billet forming equipment in continuous steel casting and it is also the cor....

Moc-k100 Mould Online Oscillation Monitoring System - By WuhanCenterRise - On Friday 9 September 2022 1:51 am: mould online oscillation monitoring system

overview

mold is the casting billet forming equipment in continuous steel casting and it is also the cor.... Import Export Startup Stories

Import Export Startup Stories

Share Your Story & Get Listed at StartImportExport.com- Taizhou Huangyan Chengxun Plastic Mould Factory: Sissi Of Taizhou Huangyan Chengxun Plastic Mould Factory From China

- Gltak Automobile Germany Co Ltd : Sophie Of GLTAK Automobile Germany, A Heavy Duty Truck Spare Parts Production Company From China

- Nice Mold Industrials Ltd: Peter Pi oF Nice Mold Industrials Ltd, A Mold Maker From China

- Mag Makina imalat: Mustafa Yildiz Of Mag Makina Imalat From Turkey For Marine, Automotive And Heavy Equipment Parts

- Aisi Machinery Co Ltd: Donald Of Aisi Machinery, A Supplier Of Concrete Machinery From China

Plastic injection molds Classification Navigation

Plastic injection molds Classification Navigation

Main - Industrial Manufacturing and Processing Machinery and Accessories - Industrial process machinery and equipment and supplies - Rubber and plastic processing machinery and equipment and supplies - Plastic injection molds [211]

TradersCity.com shall not be held liable for any user posted/submitted content including but not limited to trade leads, profiles, images, and any other data. TradersCity.com does not and did not verify any of users posted/submitted data nor is implicitly or explicitly recommending these business offers. TradersCity does not verify truthfulness, accuracy, completeness, nor legality of any businesses, services, and leads posted here. TradersCity does not represent Sellers or Buyers in any transaction between users of the website and is unable to make any opinion in regard to their performance in any transaction. TradersCity neither guarantees nor undertakes in any dispute between sellers and buyers. Protect your business from fraud by trading safely