A free import export trade leads B2B marketplace since 1996 for manufacturers, suppliers, exporters, importers, buyers, sellers, wholesalers, freight forwarders, shippers, trade shows, exhibits, and export management.

Hello visitor from USA - 53 visiting from

USA - 53 visiting from  22 USA

22 USA  12 Canada

12 Canada  6 Germany

6 Germany  3 Ukraine

3 Ukraine  3 France

3 France  3 Belgium

3 Belgium  1 Iran

1 Iran  1 Singapore

1 Singapore  1 UK

1 UK  1 Czech Republic

1 Czech Republic

Hello visitor from

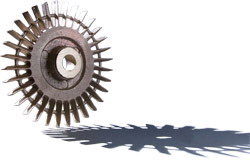

Cast Iron And Non-ferrous Metals Foundry

Posted at: Offers to Sell and Export | Posted on: Thursday 27 March 2008 12:34 pm | Poster last visit: Monday 7 April 2008 |

Product Description:

The one of plants included in the Hydro-Vacuum's group is the Foundry, which produce a wide assortment

of castings for its own and for many customers needs-especially foreign customers.

Process engineering:

- Hydro-Vacuum S.A. Foundry is excellent for batch deliveries which require to use many kind of different technologies. The capacity of our Foundry is about 6 000 tons per year

- The foudry is equipped with modern, not troublesome devices, including medium frequency electric furnaces.

- Our own Pattern Shop prepares patterns made of wood, metals and epoxide resins.

- Metal melting processes are made in the induction furnaces, moulding sands are prepared in the automatic, electronically controled sand conditioning plant equipped with vibro-fluidizating disintergrator-refrigerating machine.

- Using manual technologies.

The cores are prepared using the following technologies:

- oil mass,

- cold core box method using Novanol 140 binder, hardened using CO2,

- hot core box method,

- by ceraminc Shaw's method, both manually and by machine.

The Moulding shop is equipped with automatic foundry lines of Disamatic, Webac and jolt-moulding machines.

Materials casted by the foundry:

Our production includes mainly high grade castings of grey cast iron, ductile cast iron, high chromium cast iron, copper-molybdenum cast iron and also castings made of non-ferrous metals like brass MK 80 and bronzes B 101, B 555.

Foundry processes are covered by Intergrated Quality Management System, Environmental Management System conformable to:

- ISO 9001:2000

- ISO 14001:1996

- PN-N - 18001:1999

Technical specification:

cast iron - cast iron with flake graphite (EN-GJL 150, EN-GJL 250) - weight up to 300 kg

cast iron - cast iron with nodular graphite (EN-GJS 350-22 LT, EN-GJS 400-15 U, EN-GJS 400-18 U-LT-2 acc. to DIN A563/ASTM A395) - weight up to 300 kg

alloy cast iron - chromium cast iron (ZbCr16 - 14-17% of chromium, ZbCr32 - 28-34% of chromium) - weight up to 300 kg

alloy cast iron - copper cast iron (ZlCu1,6 - 1,2-2,0% of copper) - weight up to 300 kg

non-ferrous metals - phosphor-tin bronze (CuSn10 P - B101 - copper, 9-11% of tin, 0,8-1,2% of phosphor) - weight up to 80 kg

non ferrous metals - lead-tin-zinc bronze (CuSn5Zn5Pb5 - B555 - copper, 4-6% of tin, 4-6% of zinc, 4-6% of lead) - weight up to 80 kg

non ferrous metals - aluminium-ferric-manganese bronze (CuAl10Fe3Mn2 -BA1032 - copper, 9-11% of aluminium, 2-4% of iron, 1,2% of manganese) - weight up to 80 kg

non ferrous metals - silicon brass (CuZn16Si3,5 - MK80 - copper, 79-81% of brass, 2,5-4,5% of silicon, zinc) - weight up to 80 kg.

Company Contact:

Contact Name: Sales

Company Name: Hydro-Vacuum S.A.

Email:

Tel: +48 (56) 45 07 547

Fax: +48 (56) 45 07 346

Street Address: Droga Jeziorna 8

86-303 Grudziądz

Poland

Website: http://www.hydro-vacuum.com.pl

Member name: Hydrovacuumsa

Country: Poland

Poland

Member Since: 25 March 2008

Total Leads: 38 Hydrovacuumsa Import Export Business Leads

Business focus: Pumps, Motors, Protection, Control Systems, Sewage Pumping Stations, Pressure Boosting Systems

Chat:

Verify: Safe Import Export Tips

of castings for its own and for many customers needs-especially foreign customers.

Process engineering:

- Hydro-Vacuum S.A. Foundry is excellent for batch deliveries which require to use many kind of different technologies. The capacity of our Foundry is about 6 000 tons per year

- The foudry is equipped with modern, not troublesome devices, including medium frequency electric furnaces.

- Our own Pattern Shop prepares patterns made of wood, metals and epoxide resins.

- Metal melting processes are made in the induction furnaces, moulding sands are prepared in the automatic, electronically controled sand conditioning plant equipped with vibro-fluidizating disintergrator-refrigerating machine.

- Using manual technologies.

The cores are prepared using the following technologies:

- oil mass,

- cold core box method using Novanol 140 binder, hardened using CO2,

- hot core box method,

- by ceraminc Shaw's method, both manually and by machine.

The Moulding shop is equipped with automatic foundry lines of Disamatic, Webac and jolt-moulding machines.

Materials casted by the foundry:

Our production includes mainly high grade castings of grey cast iron, ductile cast iron, high chromium cast iron, copper-molybdenum cast iron and also castings made of non-ferrous metals like brass MK 80 and bronzes B 101, B 555.

Foundry processes are covered by Intergrated Quality Management System, Environmental Management System conformable to:

- ISO 9001:2000

- ISO 14001:1996

- PN-N - 18001:1999

Technical specification:

cast iron - cast iron with flake graphite (EN-GJL 150, EN-GJL 250) - weight up to 300 kg

cast iron - cast iron with nodular graphite (EN-GJS 350-22 LT, EN-GJS 400-15 U, EN-GJS 400-18 U-LT-2 acc. to DIN A563/ASTM A395) - weight up to 300 kg

alloy cast iron - chromium cast iron (ZbCr16 - 14-17% of chromium, ZbCr32 - 28-34% of chromium) - weight up to 300 kg

alloy cast iron - copper cast iron (ZlCu1,6 - 1,2-2,0% of copper) - weight up to 300 kg

non-ferrous metals - phosphor-tin bronze (CuSn10 P - B101 - copper, 9-11% of tin, 0,8-1,2% of phosphor) - weight up to 80 kg

non ferrous metals - lead-tin-zinc bronze (CuSn5Zn5Pb5 - B555 - copper, 4-6% of tin, 4-6% of zinc, 4-6% of lead) - weight up to 80 kg

non ferrous metals - aluminium-ferric-manganese bronze (CuAl10Fe3Mn2 -BA1032 - copper, 9-11% of aluminium, 2-4% of iron, 1,2% of manganese) - weight up to 80 kg

non ferrous metals - silicon brass (CuZn16Si3,5 - MK80 - copper, 79-81% of brass, 2,5-4,5% of silicon, zinc) - weight up to 80 kg.

Company Contact:

Contact Name: Sales

Company Name: Hydro-Vacuum S.A.

Email:

Tel: +48 (56) 45 07 547

Fax: +48 (56) 45 07 346

Street Address: Droga Jeziorna 8

86-303 Grudziądz

Poland

Website: http://www.hydro-vacuum.com.pl

Member name: Hydrovacuumsa

Country:

Member Since: 25 March 2008

Total Leads: 38 Hydrovacuumsa Import Export Business Leads

Business focus: Pumps, Motors, Protection, Control Systems, Sewage Pumping Stations, Pressure Boosting Systems

Chat:

Verify: Safe Import Export Tips

Similar Suppliers And Manufacturers Import Export Trade Leads

Similar Suppliers And Manufacturers Import Export Trade Leads

Jis Marine Cast Iron / Cast Steel Valves - By FuzhouHaituoMarineValve - On Friday 6 May 2022 9:21 am: cast steel material

1 globe valve f7311 globe valve f7319 globe valve f7313

2 hull globe valve f7365 screw down check globe valve f7471

3....

Jis Marine Cast Iron / Cast Steel Valves - By FuzhouHaituoMarineValve - On Friday 6 May 2022 9:21 am: cast steel material

1 globe valve f7311 globe valve f7319 globe valve f7313

2 hull globe valve f7365 screw down check globe valve f7471

3.... Alloy Cast Steel Rolls-cast Iron Rolls - By LONSUNMETALLURGY - On Thursday 16 June 2022 2:09 am: cast steel rolls are made by high quality melted steel with arc furnace and refiner with advanced casting and heat treatment procedure the rolls also....

Alloy Cast Steel Rolls-cast Iron Rolls - By LONSUNMETALLURGY - On Thursday 16 June 2022 2:09 am: cast steel rolls are made by high quality melted steel with arc furnace and refiner with advanced casting and heat treatment procedure the rolls also.... Cast Iron Cookware Set - By dingruncookware - On Thursday 6 April 2023 8:20 am: cast iron skillets set belongs in every kitchen

using the right cookware when preparing your favorite meal is important aside from making your prep....

Cast Iron Cookware Set - By dingruncookware - On Thursday 6 April 2023 8:20 am: cast iron skillets set belongs in every kitchen

using the right cookware when preparing your favorite meal is important aside from making your prep.... Nodular Cast Iron Tree Grate - By kehuacasting - On Tuesday 24 May 2022 1:44 am: cast iron tree grate

nodular cast iron tree grate customized processing with drawings and samples

material nodular cast iron

strong adaptability ....

Nodular Cast Iron Tree Grate - By kehuacasting - On Tuesday 24 May 2022 1:44 am: cast iron tree grate

nodular cast iron tree grate customized processing with drawings and samples

material nodular cast iron

strong adaptability .... Cast Iron Machinery Bench Mounting Platform - By kehuacasting - On Tuesday 24 May 2022 1:44 am: cast iron machinery bench mounting platform

the scribing platform is used for various inspection tasks such as the reference plane for precision mea....

Cast Iron Machinery Bench Mounting Platform - By kehuacasting - On Tuesday 24 May 2022 1:44 am: cast iron machinery bench mounting platform

the scribing platform is used for various inspection tasks such as the reference plane for precision mea.... High Chrome Cast Iron Rolls From Lonsun - By LONSUNMETALLURGY - On Thursday 30 June 2022 7:14 am: cast iron roll with lower carbon content of 1 0-1 8% the lower carbon grades are true steel with no eutectic carbides and higher carbon grades have so....

High Chrome Cast Iron Rolls From Lonsun - By LONSUNMETALLURGY - On Thursday 30 June 2022 7:14 am: cast iron roll with lower carbon content of 1 0-1 8% the lower carbon grades are true steel with no eutectic carbides and higher carbon grades have so.... Wholesale 12 Inch Cast Iron Frying Pan - By sarchicookware - On Friday 27 October 2023 7:50 am: cast iron skillet is the perfect vessel for family dinners whether you re searing steaks roasting a chicken or cooking a one-dish meal this belove....

Wholesale 12 Inch Cast Iron Frying Pan - By sarchicookware - On Friday 27 October 2023 7:50 am: cast iron skillet is the perfect vessel for family dinners whether you re searing steaks roasting a chicken or cooking a one-dish meal this belove.... Cast Iron Duo Plate Check Valve - By valvescenter - On Monday 13 February 2023 7:35 am: cast iron duo plate check valve

fasten screw

effectively prevent the shaft from travelling prevent valve work from failing and shaft end from leaking

body

short face to face ....

Cast Iron Duo Plate Check Valve - By valvescenter - On Monday 13 February 2023 7:35 am: cast iron duo plate check valve

fasten screw

effectively prevent the shaft from travelling prevent valve work from failing and shaft end from leaking

body

short face to face .... Import Export Startup Stories

Import Export Startup Stories

Share Your Story & Get Listed at StartImportExport.com- Kornik Export Company: Ekambi Pramarasse Of Kornik Export Company From Thailand

- Winfys Group Inc: Andy Xiong Of Winfys Group A Dongle Manufacturer From China

- Shandong Strong Casting Co Ltd: Emily Zhao Of Shandong Strong Casting Company An OEM Manufacturer Of Iron, Steel, Aluminium, And Non-Ferrous Casting Parts

TradersCity.com shall not be held liable for any user posted/submitted content including but not limited to trade leads, profiles, images, and any other data. TradersCity.com does not and did not verify any of users posted/submitted data nor is implicitly or explicitly recommending these business offers. TradersCity does not verify truthfulness, accuracy, completeness, nor legality of any businesses, services, and leads posted here. TradersCity does not represent Sellers or Buyers in any transaction between users of the website and is unable to make any opinion in regard to their performance in any transaction. TradersCity neither guarantees nor undertakes in any dispute between sellers and buyers. Protect your business from fraud by trading safely