A free import export trade leads B2B marketplace since 1996 for manufacturers, suppliers, exporters, importers, buyers, sellers, wholesalers, freight forwarders, shippers, trade shows, exhibits, and export management.

Hello visitor from USA - 28 visiting from

USA - 28 visiting from  19 USA

19 USA  4 Germany

4 Germany  3 France

3 France  1 Hong Kong

1 Hong Kong  1 Ukraine

1 Ukraine

Hello visitor from

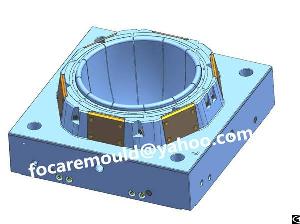

China Iml Pail Moulding, In Mold Labeling Tub Mould, Paint Box Mould, Bucket Molds

Posted at: Offers to Sell and Export | Posted on: Saturday 27 June 2015 12:21 am | Poster last visit: Wednesday 28 October 2015 |

Product Category: Main

» Industrial Manufacturing and Processing Machinery and Accessories

» Industrial process machinery and equipment and supplies

» Rubber and plastic processing machinery and equipment and supplies

» Plastic injection molds

» China Iml Pail Moulding, In Mold Labeling Tub Mould, Paint Box Mould, Bucket Molds

Product Description:

IML in mold labeling production line should include the following:

1) IML high precision mold

2) Energy

saving high speed injection molding machine

IML technology is widely used for highly output consumer goods, considering long term manufacturing, energy saving injection machine will be the best type chosed, which can save 50-60% electricity power compared to the standard molding machine.

3) Necessary auxiliary machineries

4) IML robot

Must includes the high precision CNC robot, label magazine for storage

Gripper to pick up the label from label magazine, and then transfer into the mould

Stacking unit to stack products after labeled, and sucked out from the mould

Safety doors to ensure safety manufacturing.

And of course the transport belts.

And for example 20liter paint bucket mould in mold labeling, due to mould height and injection machine toggle stroke, we usually choose robot system enter from the vertical way.

For more information, feel free to contact me.

Lucia

Company Contact:

Contact Name: Lucia Huang

Company Name: Focaremouldcoltd

Email:

Tel: 8618357616586

Fax: 8618357616586

Street Address: 15 Jinchuan Rd.

North Industry Huangyan

Taizhou, Zhejiang 318020

China

Website: http://www.focaremould.com

Member name: FocareMouldCoLtd

Country: China

China

Member Since: 26 June 2015

Total Leads: 38 FocareMouldCoLtd Import Export Business Leads

Business focus: Injection Molds, Moulds

Chat:

Verify: Safe Import Export Tips

1) IML high precision mold

2) Energy

saving high speed injection molding machine

IML technology is widely used for highly output consumer goods, considering long term manufacturing, energy saving injection machine will be the best type chosed, which can save 50-60% electricity power compared to the standard molding machine.

3) Necessary auxiliary machineries

4) IML robot

Must includes the high precision CNC robot, label magazine for storage

Gripper to pick up the label from label magazine, and then transfer into the mould

Stacking unit to stack products after labeled, and sucked out from the mould

Safety doors to ensure safety manufacturing.

And of course the transport belts.

And for example 20liter paint bucket mould in mold labeling, due to mould height and injection machine toggle stroke, we usually choose robot system enter from the vertical way.

For more information, feel free to contact me.

Lucia

Company Contact:

Contact Name: Lucia Huang

Company Name: Focaremouldcoltd

Email:

Tel: 8618357616586

Fax: 8618357616586

Street Address: 15 Jinchuan Rd.

North Industry Huangyan

Taizhou, Zhejiang 318020

China

Website: http://www.focaremould.com

Member name: FocareMouldCoLtd

Country:

Member Since: 26 June 2015

Total Leads: 38 FocareMouldCoLtd Import Export Business Leads

Business focus: Injection Molds, Moulds

Chat:

Verify: Safe Import Export Tips

Similar Suppliers And Manufacturers Import Export Trade Leads

Similar Suppliers And Manufacturers Import Export Trade Leads

Freestanding Tub - By HangzhouEbathImport - On Monday 17 October 2022 3:36 am: tub is one of the most popular additions to any home we offer 48 x 48 soaking tub and bathtub 30 x 48

with 48 quot x 48 quot dimensions this bat....

Freestanding Tub - By HangzhouEbathImport - On Monday 17 October 2022 3:36 am: tub is one of the most popular additions to any home we offer 48 x 48 soaking tub and bathtub 30 x 48

with 48 quot x 48 quot dimensions this bat.... Freestanding Tub 48 Inches - By HangzhouEbathImport - On Monday 17 October 2022 3:38 am: tub

48 inch freestanding tub is easy to move around- perfect for any bathroom

extra large bathtub with a deep end and a wide base- perfect for soak....

Freestanding Tub 48 Inches - By HangzhouEbathImport - On Monday 17 October 2022 3:38 am: tub

48 inch freestanding tub is easy to move around- perfect for any bathroom

extra large bathtub with a deep end and a wide base- perfect for soak.... Bath Tub Pillow - By knitfabric - On Saturday 9 July 2022 1:05 am: mold and mildew the thousands of “x-90” middle hollow structure can effectively prevent the breeding of dust-mite take care of skin healthy reduce....

Bath Tub Pillow - By knitfabric - On Saturday 9 July 2022 1:05 am: mold and mildew the thousands of “x-90” middle hollow structure can effectively prevent the breeding of dust-mite take care of skin healthy reduce.... Freestanding Tub 48inch - By HangzhouEbathImport - On Monday 17 October 2022 3:34 am: tub that is 48 inches wide if so you may be interested in the freestanding bathtub from jacuzzi this bathtub is made from high-quality materials an....

Freestanding Tub 48inch - By HangzhouEbathImport - On Monday 17 October 2022 3:34 am: tub that is 48 inches wide if so you may be interested in the freestanding bathtub from jacuzzi this bathtub is made from high-quality materials an.... Long Soaking Tub 48 Inch - By HangzhouEbathImport - On Monday 17 October 2022 3:37 am: tub manufacturers and suppliers

amp #12288 amp #12288 ebath is one of the leading 48 inch freestanding soaking tub manufacturers and suppliers wit....

Long Soaking Tub 48 Inch - By HangzhouEbathImport - On Monday 17 October 2022 3:37 am: tub manufacturers and suppliers

amp #12288 amp #12288 ebath is one of the leading 48 inch freestanding soaking tub manufacturers and suppliers wit.... American Style Freestanding Tub - By HangzhouEbathImport - On Thursday 29 September 2022 7:35 am: tub supplier

model no dh6849

color white

size

1700x800x580

1600x800x580

1500x800x580

1400x750x580

1300x700x580

cabinet finish lacquer cus....

American Style Freestanding Tub - By HangzhouEbathImport - On Thursday 29 September 2022 7:35 am: tub supplier

model no dh6849

color white

size

1700x800x580

1600x800x580

1500x800x580

1400x750x580

1300x700x580

cabinet finish lacquer cus.... Freestanding Soaking Tub 48 Inch - By HangzhouEbathImport - On Monday 17 October 2022 3:36 am: tub

48 inch freestanding tub is easy to move around- perfect for any bathroom

extra large bathtub with a deep end and a wide base- perfect for soak....

Freestanding Soaking Tub 48 Inch - By HangzhouEbathImport - On Monday 17 October 2022 3:36 am: tub

48 inch freestanding tub is easy to move around- perfect for any bathroom

extra large bathtub with a deep end and a wide base- perfect for soak.... Freestanding Soaking Tub 48 Inch Ebath Bathroom Products - By HangzhouEbathImport - On Thursday 29 September 2022 7:05 am: tub

8 elegant looking and comfortable bathtub

9 the size specification and color can be custom-made bathtub

about 48 inch freestanding bathtub

do....

Freestanding Soaking Tub 48 Inch Ebath Bathroom Products - By HangzhouEbathImport - On Thursday 29 September 2022 7:05 am: tub

8 elegant looking and comfortable bathtub

9 the size specification and color can be custom-made bathtub

about 48 inch freestanding bathtub

do.... Import Export Startup Stories

Import Export Startup Stories

Share Your Story & Get Listed at StartImportExport.com- Taizhou Huangyan Chengxun Plastic Mould Factory: Sissi Of Taizhou Huangyan Chengxun Plastic Mould Factory From China

- Nice Mold Industrials Ltd: Peter Pi oF Nice Mold Industrials Ltd, A Mold Maker From China

- Jie Mei Precision Mould Ltd: John Zhang Of Jie Mei Precision Mould From China

- SpecsPro LLC: Cathy Huang Of SpecsPro LLC Integrated Sourcing Supply Chain Solutions From USA

- Prelead Industy Co Ltd: Norman Cao Of Prelead Industry, A Trading Company Specializing In Industrial And Electrical Products And Plastic Injection Molding From China

Plastic injection molds Classification Navigation

Plastic injection molds Classification Navigation

Main - Industrial Manufacturing and Processing Machinery and Accessories - Industrial process machinery and equipment and supplies - Rubber and plastic processing machinery and equipment and supplies - Plastic injection molds [211]

TradersCity.com shall not be held liable for any user posted/submitted content including but not limited to trade leads, profiles, images, and any other data. TradersCity.com does not and did not verify any of users posted/submitted data nor is implicitly or explicitly recommending these business offers. TradersCity does not verify truthfulness, accuracy, completeness, nor legality of any businesses, services, and leads posted here. TradersCity does not represent Sellers or Buyers in any transaction between users of the website and is unable to make any opinion in regard to their performance in any transaction. TradersCity neither guarantees nor undertakes in any dispute between sellers and buyers. Protect your business from fraud by trading safely