A free import export trade leads B2B marketplace since 1996 for manufacturers, suppliers, exporters, importers, buyers, sellers, wholesalers, freight forwarders, shippers, trade shows, exhibits, and export management.

Hello visitor from USA - 40 visiting from

USA - 40 visiting from  20 USA

20 USA  13 Canada

13 Canada  2 France

2 France  2 UK

2 UK  2 Brazil

2 Brazil  1 Ukraine

1 Ukraine

Hello visitor from

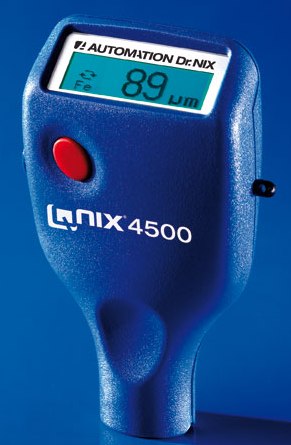

Coating Thickness Gauge, Paint Meter, Dry Film Thickness Gage

Posted at: Offers to Sell and Export | Posted on: Tuesday 5 May 2009 9:10 pm | Poster last visit: Thursday 23 July 2009 |

Product Category: Main

» Manufacturing Components and Supplies

» Paints and primers and finishes

» Paints and primers

» Coating paints

» Coating Thickness Gauge, Paint Meter, Dry Film Thickness Gage

Product Description:

QNix® 4500 was developed particularly for measuring tasks

in the automobile as well as fastidious painting

applications

in other industries. This com-pact gauge permits extremely

precise measurements of lac-quer and corrosion protection

thicknesses, both on steel and iron as well as on non-ferrous

metals such as aluminum, zinc, copper.

Automatic substrate recognition

• Increased measuring speed

• Backlight

• Graphic Display with high resolution

• Extended measuring range – Fe & NFe (both 120mil -3000 microns)

Extremely precise:

High measuring accuracy over

the entire measuring range.

Simple operation:

No calibration. Only one button.

One-hand operation.

Product advantages:

Optimal LCD display:

With the QNix® 4500 precise

measurements on steel, iron and non-

ferrous metals become simply perfect.

The automatic substrate recognition

makes the measuring easier and saver.

No calibration. With high precision

over the entire measuring range: Fe and

NFe from 0 to 3000 μm.

Gauge for standard applications -

simple, fast measurements.

Large clear numbers for optimal

readability

One-hand operation. Only one button.

Precise representation of readings, battery condition and mode of

operation

No calibration.

Automatic On/Off switching.

Backlight

High precision over the entire

measuring range:

Fe and NFe from 0 to 120 mil.

Scope of supply:

The sensitive measuring probe

of the extremely small, light and handy

QNix® 4500 is integrated into the gauge.

It is a equipped with a readable LCD

that informs about readings, battery

condition and mode of operation.

Broad spectrum of use for non-

destructive measurements on steel, iron and non-ferrous metals such as

aluminum, zinc, copper and brass.

Coating thickness gauge

QNix® 4500 (or QNix® 4200).

Gauge carrying case with reference

plates.

Compact design with integrated

probe.

2 x 1, 5 V Mignon Batteries

(Type AA Alkali).

Innovative, proven technology: Hall

sensor and Eddy Current technology.

Test Certificate.

Acoustic signal for confirmation that

measurement has been taken.

Instruction manual.

Non wearing ruby probe tip for long

term use.

For measurements on steel and iron, the identically designed QNix® 4200 is

available.

only QNix® 4500: Automatic substrate

recognition

Principle of Operation

Two magnetic measuring principles:

NFe: Eddy Current

(QNix® 4500 only)

Fe: Magnetic-Flux /

Hall Effect

See Fe*

Standards & Regulation

Din en iso 2808, din 50981, iso 2178, BS 5411 (3 & 11), BS 3900 - C5, ASTM B 499, ASTM D 1186, ASTM D 7091 (only QNix® 4500:

Din 50984, iso 2360, astm d 1400)

Probe Type

integrated

Measuring Range

Fe: 0, 0 - 120 mil

NFe: 0, 0 -120 mil

(QNix® 4500 only )

Measuring Frequency

Single measurement: 600 ms

Display Metric

from 0, 0 - 999 in μm, from 1000 μm in mm

Resolution

1 μm in the range up to 999 μm, 0, 01 mm in the range from 1 mm

Accuracy according

to Automation Dr. Nix Standards

± (2 μm + 3% of the readings)

Minimum Measuring Area (in mm x mm)

10 x 10

Minimum Curvature

convex : 5mm, concave : 25mm

DB E 4500/4200 DK 04/07/3000. Subject to change.

Minimum Substrate Thickness

Fe: 0, 2 mm

NFe: 0, 05 mm

(QNix® 4500 only)

Display

Graphic display with backlight

Temperature Range

0 - 50 °c

Permitted Storage Temperature

-10 °c - 60 °c

Power Supply

2 x Batteries: 1.5V (Type AA Alkali)

Dimensions (L x W x H in mm)

100 x 60 x 27

Weight incl. Battery

appr. 105 g

Fe*

Measuring of non-ferromagnetic coatings on ferromagnetic substrate, for example

Company Contact:

Contact Name: Francis Payne Awafong

Company Name: Testcoat, Inc.

Email:

Tel: 1-717-334-3372

Fax: 1-717-334-0238

Street Address: 1685 Baltimore St.

Ste. C Gettysburg, PA 17325, USA

Member name: TestCoat

Country: Usa

Usa

Member Since: 05 May 2009

Total Leads: 2 TestCoat Import Export Business Leads

Business focus: Coating Thickness Gauge, Paint Meter, Dry Film Thickness Gauge, Paint Gauge

Chat:

Verify: Safe Import Export Tips

in the automobile as well as fastidious painting

applications

in other industries. This com-pact gauge permits extremely

precise measurements of lac-quer and corrosion protection

thicknesses, both on steel and iron as well as on non-ferrous

metals such as aluminum, zinc, copper.

Automatic substrate recognition

• Increased measuring speed

• Backlight

• Graphic Display with high resolution

• Extended measuring range – Fe & NFe (both 120mil -3000 microns)

Extremely precise:

High measuring accuracy over

the entire measuring range.

Simple operation:

No calibration. Only one button.

One-hand operation.

Product advantages:

Optimal LCD display:

With the QNix® 4500 precise

measurements on steel, iron and non-

ferrous metals become simply perfect.

The automatic substrate recognition

makes the measuring easier and saver.

No calibration. With high precision

over the entire measuring range: Fe and

NFe from 0 to 3000 μm.

Gauge for standard applications -

simple, fast measurements.

Large clear numbers for optimal

readability

One-hand operation. Only one button.

Precise representation of readings, battery condition and mode of

operation

No calibration.

Automatic On/Off switching.

Backlight

High precision over the entire

measuring range:

Fe and NFe from 0 to 120 mil.

Scope of supply:

The sensitive measuring probe

of the extremely small, light and handy

QNix® 4500 is integrated into the gauge.

It is a equipped with a readable LCD

that informs about readings, battery

condition and mode of operation.

Broad spectrum of use for non-

destructive measurements on steel, iron and non-ferrous metals such as

aluminum, zinc, copper and brass.

Coating thickness gauge

QNix® 4500 (or QNix® 4200).

Gauge carrying case with reference

plates.

Compact design with integrated

probe.

2 x 1, 5 V Mignon Batteries

(Type AA Alkali).

Innovative, proven technology: Hall

sensor and Eddy Current technology.

Test Certificate.

Acoustic signal for confirmation that

measurement has been taken.

Instruction manual.

Non wearing ruby probe tip for long

term use.

For measurements on steel and iron, the identically designed QNix® 4200 is

available.

only QNix® 4500: Automatic substrate

recognition

Principle of Operation

Two magnetic measuring principles:

NFe: Eddy Current

(QNix® 4500 only)

Fe: Magnetic-Flux /

Hall Effect

See Fe*

Standards & Regulation

Din en iso 2808, din 50981, iso 2178, BS 5411 (3 & 11), BS 3900 - C5, ASTM B 499, ASTM D 1186, ASTM D 7091 (only QNix® 4500:

Din 50984, iso 2360, astm d 1400)

Probe Type

integrated

Measuring Range

Fe: 0, 0 - 120 mil

NFe: 0, 0 -120 mil

(QNix® 4500 only )

Measuring Frequency

Single measurement: 600 ms

Display Metric

from 0, 0 - 999 in μm, from 1000 μm in mm

Resolution

1 μm in the range up to 999 μm, 0, 01 mm in the range from 1 mm

Accuracy according

to Automation Dr. Nix Standards

± (2 μm + 3% of the readings)

Minimum Measuring Area (in mm x mm)

10 x 10

Minimum Curvature

convex : 5mm, concave : 25mm

DB E 4500/4200 DK 04/07/3000. Subject to change.

Minimum Substrate Thickness

Fe: 0, 2 mm

NFe: 0, 05 mm

(QNix® 4500 only)

Display

Graphic display with backlight

Temperature Range

0 - 50 °c

Permitted Storage Temperature

-10 °c - 60 °c

Power Supply

2 x Batteries: 1.5V (Type AA Alkali)

Dimensions (L x W x H in mm)

100 x 60 x 27

Weight incl. Battery

appr. 105 g

Fe*

Measuring of non-ferromagnetic coatings on ferromagnetic substrate, for example

Company Contact:

Contact Name: Francis Payne Awafong

Company Name: Testcoat, Inc.

Email:

Tel: 1-717-334-3372

Fax: 1-717-334-0238

Street Address: 1685 Baltimore St.

Ste. C Gettysburg, PA 17325, USA

Member name: TestCoat

Country:

Member Since: 05 May 2009

Total Leads: 2 TestCoat Import Export Business Leads

Business focus: Coating Thickness Gauge, Paint Meter, Dry Film Thickness Gauge, Paint Gauge

Chat:

Verify: Safe Import Export Tips

Similar Suppliers And Manufacturers Import Export Trade Leads

Similar Suppliers And Manufacturers Import Export Trade Leads

Clear Tpu Paint Protection Film - By UPPF - On Thursday 21 December 2023 2:19 am: coating technology platicoat™ for stain-resistance is specifically serving our customer besides clear ppf is a transparent adhesive film for protect....

Clear Tpu Paint Protection Film - By UPPF - On Thursday 21 December 2023 2:19 am: coating technology platicoat™ for stain-resistance is specifically serving our customer besides clear ppf is a transparent adhesive film for protect.... Spike Roller Floor Decor Paint Tool Professional Levering Epoxy Floor Coating - By gsbpainttool - On Saturday 23 December 2023 6:53 am: coating and floor preparation projects

premium construction our good quality spike roller is constructed with high-quality materials to ensure opt....

Spike Roller Floor Decor Paint Tool Professional Levering Epoxy Floor Coating - By gsbpainttool - On Saturday 23 December 2023 6:53 am: coating and floor preparation projects

premium construction our good quality spike roller is constructed with high-quality materials to ensure opt.... Tz1600-30 Single-coating Aluminium Coating Line - By ltcoatingline - On Thursday 12 May 2022 6:22 am: coating aluminium coating line

coating line features

this is an economic type of coating line apply to most acp top bottom coil coating product th....

Tz1600-30 Single-coating Aluminium Coating Line - By ltcoatingline - On Thursday 12 May 2022 6:22 am: coating aluminium coating line

coating line features

this is an economic type of coating line apply to most acp top bottom coil coating product th.... Rtm-2610 Digital Dew Point Meter Absolute Humidity Meter - By realltech - On Tuesday 18 April 2023 8:45 am: meter rtm-2610

1 introduction

rtm-2610 is a high accuracy of professional dew point meter it is able to measure ambient temperature dew point tem....

Rtm-2610 Digital Dew Point Meter Absolute Humidity Meter - By realltech - On Tuesday 18 April 2023 8:45 am: meter rtm-2610

1 introduction

rtm-2610 is a high accuracy of professional dew point meter it is able to measure ambient temperature dew point tem.... Prepaid Water Meter Prepayment Water Meter - By watermeters - On Friday 20 May 2022 7:43 am: meter co ltd focus on r amp amp d and produce mechanical water meter smart water meter ultrasonic water meter and

flow meter since 1995 we not o....

Prepaid Water Meter Prepayment Water Meter - By watermeters - On Friday 20 May 2022 7:43 am: meter co ltd focus on r amp amp d and produce mechanical water meter smart water meter ultrasonic water meter and

flow meter since 1995 we not o.... Paint Tape For Walls - By gsbpainttool - On Saturday 23 December 2023 6:52 am: painter s tape made in china

high performance tape designed to adhere quickly and easily to desired surface

clean removal adhesive system will n....

Paint Tape For Walls - By gsbpainttool - On Saturday 23 December 2023 6:52 am: painter s tape made in china

high performance tape designed to adhere quickly and easily to desired surface

clean removal adhesive system will n.... Wholesale High Performance Wrap Film Stretch Industry Grade Cast Stretch Wrap Film Vietnam - By Hanpak - On Friday 29 December 2023 8:47 am: meter into five meters use less stretch film per wrap cost- saving while have greater efficency in wrapping

product name

stretch film stretch ....

Wholesale High Performance Wrap Film Stretch Industry Grade Cast Stretch Wrap Film Vietnam - By Hanpak - On Friday 29 December 2023 8:47 am: meter into five meters use less stretch film per wrap cost- saving while have greater efficency in wrapping

product name

stretch film stretch .... Precipitated Calcium Carbonate Paint Filler - By diamondnano - On Thursday 14 July 2022 8:24 am: coating resin acid

package 25 kg bag

certifications iso 9001

product description

tdd is our precipitated calcium carbonate coated with resin ac....

Precipitated Calcium Carbonate Paint Filler - By diamondnano - On Thursday 14 July 2022 8:24 am: coating resin acid

package 25 kg bag

certifications iso 9001

product description

tdd is our precipitated calcium carbonate coated with resin ac.... Import Export Startup Stories

Import Export Startup Stories

Share Your Story & Get Listed at StartImportExport.com- Fujian Billion High Tech Material Industry Co Ltd: Janey Of Fujian Billion High Tech Material Industry From China

- Ningbohi Tech Wede Motor Machines Co Ltd: Emily Of Ningbo Hitech Wede Motor Machines From China

- Zhongshan Shangfang Instrument Meter Co Ltd: Sharon Lee Of Zhongshan Shangfang Instrument Meter From China

- Birchhill Plywood China Xuzhou Inc: Steven Yin Of Birchhill Plywood, A Manufacturer And Exporter Of Plywood Products From China

Coating paints Classification Navigation

Coating paints Classification Navigation

Main - Manufacturing Components and Supplies - Paints and primers and finishes - Paints and primers - Coating paints [19]

TradersCity.com shall not be held liable for any user posted/submitted content including but not limited to trade leads, profiles, images, and any other data. TradersCity.com does not and did not verify any of users posted/submitted data nor is implicitly or explicitly recommending these business offers. TradersCity does not verify truthfulness, accuracy, completeness, nor legality of any businesses, services, and leads posted here. TradersCity does not represent Sellers or Buyers in any transaction between users of the website and is unable to make any opinion in regard to their performance in any transaction. TradersCity neither guarantees nor undertakes in any dispute between sellers and buyers. Protect your business from fraud by trading safely