A free import export trade leads B2B marketplace since 1996 for manufacturers, suppliers, exporters, importers, buyers, sellers, wholesalers, freight forwarders, shippers, trade shows, exhibits, and export management.

Hello visitor from USA - 313 visiting from

USA - 313 visiting from  294 USA

294 USA  7 Singapore

7 Singapore  4 Brazil

4 Brazil  4 Hong Kong

4 Hong Kong  2 Europe

2 Europe  1 UK

1 UK  1 Uzbekistan

1 Uzbekistan

Hello visitor from

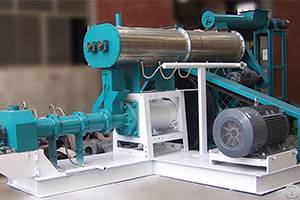

Do You Know Tilapia Fish Feed Production Line Large Fish Feed Extruder

Posted at: Offers to Sell and Export | Posted on: Wednesday 25 March 2020 9:09 am | Poster last visit: Thursday 28 October 2021 | Targeted Countries: Iran | Nigeria | Rwanda

Product Category: Main

» Industrial Manufacturing and Processing Machinery and Accessories

» Raw materials processing machinery

» Machinery for working wood and stone and ceramic and the like

» Milling machines

» Do You Know Tilapia Fish Feed Production Line Large Fish Feed Extruder

Product Description:

With the development of the aquaculture industry in the direction of large-scale, intensive and professional,

its requirements for aquaculture feeds are becoming higher and higher. The traditional powder compound feed, pellet compound feed, and other types of compound feed all have disadvantages, such as poor water stability, fast settling rate, easy to cause feed loss, and water pollution. It is no longer suitable for the development of modern aquaculture. Puffed fish feed has completely solved these drawbacks, and more and more aquaculture farmers and feed mills have installed puffed feed machine equipment.

Tilapia Feed Production Line Process: Large fish feed extruder production line

Raw material crushing → Preparation of raw materials (corn meal, soybean meal, starch, fish meal, etc.) → feed mixer → conveyor → twin screw fish feed extruder → conveyor → drying equipment (electric oven, gas oil oven or steam oven) → fuel injection → double-cylinder seasoning system → cooling conveyor → screening → silo → packaging machine

Extruded Fish Feed Processing Equipment Configuration: Fish Feed Pellet Machine Hot Sale

Crusher → Mixer → Feeder → Twin Screw Fish Feed Extruder → Conveyor → Multi-layer Drying Equipment → Flavoring Machine → Cooler → Vibrating Screen → Packaging Machine

Fish feed size range: 1mm, 1.5mm, 2.0mm-10mm.

This fish feed production line can produce and process feed pellets such as catfish, grass carp, tilapia, ornamental fish, turtles, bullfrogs, and so on.

Fish Feed Production Line Equipment Introduction

1. Mixer: Adding a certain percentage of water to the raw material corn flour, rice flour, soybean flour, fish flour, meat flour, cereal flour, etc. and mix well.

2. Feeding machine: Using the motor as the power, the screw-type transport, transfer the mixed material to the hopper of the twin-screw extruder. This equipment is convenient and efficient for feeding, saving labor and high efficiency.

3. Twin-screw feed extruder: Under the condition of high-temperature high pressure and twin-screw extrusion of the mixed raw materials. The starch structure of the raw materials changes and becomes easily absorbed nutrients. It extruded through the feed mold and adjusted by rotary cutting, until the same size pellets extruded. The specific particle size and shape are obtained by changing the mold. The fish feed extruder uses advanced frequency conversion speed regulation technology, which is more energy-saving and more accurate speed control. The current and speed of the motor can be directly seen through the inverter panel to ensure the safety of the equipment.

4. Conveyor: The produced feed pellets conveyed into the multilayer drying equipment.

5. Multi-layer oven: The oven divided into electric oven, fuel oven, gas oven, and steam oven. The temperature adjusted through the control cabinet between 0 and 150 degrees. The stainless steel mesh belt is inside the oven, and the conveyance is smooth and the failure rate is low. The feed pellets circulated through a multi-layer S-shaped track, and the feed pellets dried to safe moisture content to increase the shelf life.

6. Spraying seasoning machine: The sprayer sprays oil, attractant, etc. According to the output and product properties, spray the fat on the surface of the feed, and at the same time spray the minced meat and spices, and spread evenly. After this process, the burrs on the surface of the feed pellets can be removed, making the surface of the feed pellets smoother.

7. Cooling conveyor: Reduce the surface temperature of dried feed pellets, promote the solidification of fats, reduce the pellet temperature, and easy to pack.

8. Vibrating sieve: Sieve away excess external material and granulated slag to ensure quality while ensuring the reuse of raw materials.

9. Packaging machine: Manual sealing machine and automatic packaging machine can be used.

Hope this article can help you know more about fish feed production line, if you want to build your own fish feed plant, please contact us.

Company Contact:

Contact Name: Amy Yan

Company Name: Zhengzhou Fusmar Machinery Co., Ltd

Email:

Tel: +8615838279423

Fax: +8615838279423

Street Address: No.45 Agricultural

Road, Jinshui District Zhengzhou,

Henan 450003 China

Other Contact Info:

Skype:

Website: https://www.feedpelletmills.com

Member name: FusmarMachinery

Country: China

China

Member Since: 28 May 2019

Total Leads: 216 FusmarMachinery Import Export Business Leads

Business focus: Pellet Mill, Fish Feed Machine, Charcoal Briquette Machine

Chat:

Verify: Safe Import Export Tips

its requirements for aquaculture feeds are becoming higher and higher. The traditional powder compound feed, pellet compound feed, and other types of compound feed all have disadvantages, such as poor water stability, fast settling rate, easy to cause feed loss, and water pollution. It is no longer suitable for the development of modern aquaculture. Puffed fish feed has completely solved these drawbacks, and more and more aquaculture farmers and feed mills have installed puffed feed machine equipment.

Tilapia Feed Production Line Process: Large fish feed extruder production line

Raw material crushing → Preparation of raw materials (corn meal, soybean meal, starch, fish meal, etc.) → feed mixer → conveyor → twin screw fish feed extruder → conveyor → drying equipment (electric oven, gas oil oven or steam oven) → fuel injection → double-cylinder seasoning system → cooling conveyor → screening → silo → packaging machine

Extruded Fish Feed Processing Equipment Configuration: Fish Feed Pellet Machine Hot Sale

Crusher → Mixer → Feeder → Twin Screw Fish Feed Extruder → Conveyor → Multi-layer Drying Equipment → Flavoring Machine → Cooler → Vibrating Screen → Packaging Machine

Fish feed size range: 1mm, 1.5mm, 2.0mm-10mm.

This fish feed production line can produce and process feed pellets such as catfish, grass carp, tilapia, ornamental fish, turtles, bullfrogs, and so on.

Fish Feed Production Line Equipment Introduction

1. Mixer: Adding a certain percentage of water to the raw material corn flour, rice flour, soybean flour, fish flour, meat flour, cereal flour, etc. and mix well.

2. Feeding machine: Using the motor as the power, the screw-type transport, transfer the mixed material to the hopper of the twin-screw extruder. This equipment is convenient and efficient for feeding, saving labor and high efficiency.

3. Twin-screw feed extruder: Under the condition of high-temperature high pressure and twin-screw extrusion of the mixed raw materials. The starch structure of the raw materials changes and becomes easily absorbed nutrients. It extruded through the feed mold and adjusted by rotary cutting, until the same size pellets extruded. The specific particle size and shape are obtained by changing the mold. The fish feed extruder uses advanced frequency conversion speed regulation technology, which is more energy-saving and more accurate speed control. The current and speed of the motor can be directly seen through the inverter panel to ensure the safety of the equipment.

4. Conveyor: The produced feed pellets conveyed into the multilayer drying equipment.

5. Multi-layer oven: The oven divided into electric oven, fuel oven, gas oven, and steam oven. The temperature adjusted through the control cabinet between 0 and 150 degrees. The stainless steel mesh belt is inside the oven, and the conveyance is smooth and the failure rate is low. The feed pellets circulated through a multi-layer S-shaped track, and the feed pellets dried to safe moisture content to increase the shelf life.

6. Spraying seasoning machine: The sprayer sprays oil, attractant, etc. According to the output and product properties, spray the fat on the surface of the feed, and at the same time spray the minced meat and spices, and spread evenly. After this process, the burrs on the surface of the feed pellets can be removed, making the surface of the feed pellets smoother.

7. Cooling conveyor: Reduce the surface temperature of dried feed pellets, promote the solidification of fats, reduce the pellet temperature, and easy to pack.

8. Vibrating sieve: Sieve away excess external material and granulated slag to ensure quality while ensuring the reuse of raw materials.

9. Packaging machine: Manual sealing machine and automatic packaging machine can be used.

Hope this article can help you know more about fish feed production line, if you want to build your own fish feed plant, please contact us.

Company Contact:

Contact Name: Amy Yan

Company Name: Zhengzhou Fusmar Machinery Co., Ltd

Email:

Tel: +8615838279423

Fax: +8615838279423

Street Address: No.45 Agricultural

Road, Jinshui District Zhengzhou,

Henan 450003 China

Other Contact Info:

Skype:

Website: https://www.feedpelletmills.com

Member name: FusmarMachinery

Country:

Member Since: 28 May 2019

Total Leads: 216 FusmarMachinery Import Export Business Leads

Business focus: Pellet Mill, Fish Feed Machine, Charcoal Briquette Machine

Chat:

Verify: Safe Import Export Tips

Similar Suppliers And Manufacturers Import Export Trade Leads

Similar Suppliers And Manufacturers Import Export Trade Leads

F-81395 T3ar Feed Pig Extruder Roller Bearing - By lyjhbearing - On Sunday 5 February 2023 10:42 am: feed pig extruder roller bearing

f-81395 t3ar f-81395 t3ar bearings specification as following

bearing old bearing code rows no dimensions load r....

F-81395 T3ar Feed Pig Extruder Roller Bearing - By lyjhbearing - On Sunday 5 February 2023 10:42 am: feed pig extruder roller bearing

f-81395 t3ar f-81395 t3ar bearings specification as following

bearing old bearing code rows no dimensions load r.... F-81672 T4ar Cylindrical Roller Bearing For Feed Extruder - By jinshuobearing - On Wednesday 28 June 2023 1:27 am: feed extruder

f-81672 t4ar cylindrical roller bearing for feed extruder with high efficiency high performance low noise long life customizable c....

F-81672 T4ar Cylindrical Roller Bearing For Feed Extruder - By jinshuobearing - On Wednesday 28 June 2023 1:27 am: feed extruder

f-81672 t4ar cylindrical roller bearing for feed extruder with high efficiency high performance low noise long life customizable c.... Tamdem Roller Bearing F-53871 T4ar For Feed Pig Extruder - By jinshuobearing - On Wednesday 28 June 2023 1:24 am: feed pig extruder

bearing factory model f-53871 t4ar

china bearing old type f-53871 t4ar

bearing boundary dimension 35x80x90mm

id inner diameter ....

Tamdem Roller Bearing F-53871 T4ar For Feed Pig Extruder - By jinshuobearing - On Wednesday 28 June 2023 1:24 am: feed pig extruder

bearing factory model f-53871 t4ar

china bearing old type f-53871 t4ar

bearing boundary dimension 35x80x90mm

id inner diameter .... Feed Pig Extruder Axial Roller Bearing F-51909 T3ar - By jinshuobearing - On Monday 3 July 2023 1:50 am: extruder axial roller bearing f-51909 t3ar

our products have been widely used in the fields of engineering machinery industrial pumps machine tool....

Feed Pig Extruder Axial Roller Bearing F-51909 T3ar - By jinshuobearing - On Monday 3 July 2023 1:50 am: extruder axial roller bearing f-51909 t3ar

our products have been widely used in the fields of engineering machinery industrial pumps machine tool.... Tamdem Roller Bearing F-52523-100.t6ar For Feed Pig Extruder - By jinshuobearing - On Sunday 25 June 2023 2:59 am: feed pig extruder

tandem bearings have the following characteristics

the tandem thrust cylindrical roller bearing provided by luoyang jinshuo preci....

Tamdem Roller Bearing F-52523-100.t6ar For Feed Pig Extruder - By jinshuobearing - On Sunday 25 June 2023 2:59 am: feed pig extruder

tandem bearings have the following characteristics

the tandem thrust cylindrical roller bearing provided by luoyang jinshuo preci.... Pp / Pe / Hdpe Pipe Extruder Machine Production Line - By QingdaoTrustyMachine - On Saturday 22 October 2022 2:54 am: line plastic pipe extruder pipe production line pe pipe equipment

factory supply pe water pipe making machine is mainly used in the production of ....

Pp / Pe / Hdpe Pipe Extruder Machine Production Line - By QingdaoTrustyMachine - On Saturday 22 October 2022 2:54 am: line plastic pipe extruder pipe production line pe pipe equipment

factory supply pe water pipe making machine is mainly used in the production of .... Frozen Red Tilapia Fillet - By ThaiLienExporters - On Thursday 17 November 2022 6:44 am: tilapia fillet

shelf life 24 month

weight kg 10

packing bulk ivp

freezing process iqf

size 120 150 150 200 200 300 300 400 400 600

o....

Frozen Red Tilapia Fillet - By ThaiLienExporters - On Thursday 17 November 2022 6:44 am: tilapia fillet

shelf life 24 month

weight kg 10

packing bulk ivp

freezing process iqf

size 120 150 150 200 200 300 300 400 400 600

o.... Durable Overhead Line Conductor Steel Core Transmission Line Standard Size - By HenanTanoCableCoLtd - On Friday 3 June 2022 1:28 am: durable overhead line conductor steel core transmission line standard size

brand name tano cable

model number acsr rabbit conductor

certification iso ce ccc

place of origin china

moq 1000 meters

price negot....

Durable Overhead Line Conductor Steel Core Transmission Line Standard Size - By HenanTanoCableCoLtd - On Friday 3 June 2022 1:28 am: durable overhead line conductor steel core transmission line standard size

brand name tano cable

model number acsr rabbit conductor

certification iso ce ccc

place of origin china

moq 1000 meters

price negot.... Import Export Startup Stories

Import Export Startup Stories

Share Your Story & Get Listed at StartImportExport.com- Jinan Darin Machinery Co Ltd: Chill Zhang Of Jinan Darin Machinery, A Food Machinery Manufacturer From China

- Omoshiroi Trading Co Ltd: Jack Sakana Of Omoshiroi Trading Seafood And Surimi From Thailand

- Song Bien SOBICO Co Ltd: Huyen Trang Of Song Bien SOBICO, A Frozen Seafood Supplier From Vietnam

- JMT Business : Yulian Ciobanu Of JMT Business Import And Export Of Foodstuff From Spain

- Zhangjiagang Yuanfeng Plastic Machinery CO Ltd: Nita Liang Of Zhangjiagang Yuanfeng Plastic Machinery Company From China

Milling machines Classification Navigation

Milling machines Classification Navigation

Main - Industrial Manufacturing and Processing Machinery and Accessories - Raw materials processing machinery - Machinery for working wood and stone and ceramic and the like - Milling machines [208]

TradersCity.com shall not be held liable for any user posted/submitted content including but not limited to trade leads, profiles, images, and any other data. TradersCity.com does not and did not verify any of users posted/submitted data nor is implicitly or explicitly recommending these business offers. TradersCity does not verify truthfulness, accuracy, completeness, nor legality of any businesses, services, and leads posted here. TradersCity does not represent Sellers or Buyers in any transaction between users of the website and is unable to make any opinion in regard to their performance in any transaction. TradersCity neither guarantees nor undertakes in any dispute between sellers and buyers. Protect your business from fraud by trading safely