A free import export trade leads B2B marketplace since 1996 for manufacturers, suppliers, exporters, importers, buyers, sellers, wholesalers, freight forwarders, shippers, trade shows, exhibits, and export management.

Hello visitor from USA - 39 visiting from

USA - 39 visiting from  23 USA

23 USA  8 Canada

8 Canada  2 UK

2 UK  2 Brazil

2 Brazil  1 Zimbabwe

1 Zimbabwe  1 Germany

1 Germany  1 Iran

1 Iran  1 Ukraine

1 Ukraine

Hello visitor from

Fuming Furnace

Posted at: Offers to Sell and Export | Posted on: Wednesday 2 April 2025 2:47 am | Poster last visit: Wednesday 2 April 2025 |

Product Category: Main

» Industrial Cleaning Services

» Refuse disposal and treatment

» Recycling services

» Recycling of metal

» Fuming Furnace

Product Description:

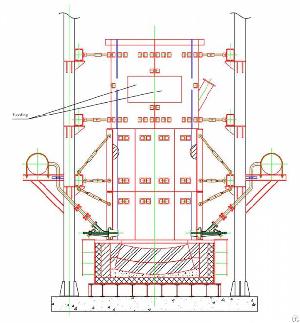

The principle of fuming is a reduction and volatilization process, which is to blow air and pulverized

coal into the slag in the fuming furnace, generate heat and carbon monoxide after combustion, keep the slag at high temperature, and make the compounds and free ZnO and PbO in the slag reduced to Zn and Pb vapors, the vapor will rise to the upper space of the furnace, meet CO2 or inhaled air and oxidize to zinc oxide and lead oxide again, and are collected in the state of soot.

The four walls of the fuming furnace are all composed of water jackets. The lowermost water jacket on the side is provided with a tuyere. The inner wall of the water jacket is welded with Φ16mm and 50mm long pins, and the distance between the nails is 50mm, so that the condensed slag adheres to it and forms slag layer protects the water jacket and reduces heat loss.

There is a slag outlet on the water jacket at the front end of the furnace.

The lower layer of the water jacket and the inclined flue are water-cooled and circulated, and the upper layer of the water jacket is cooled by vaporization.

The tuyere structure adopts a tuyere with a ball valve, and there are two branch pipes. The one near the water jacket is called the primary air coal pipe, and the one outside is the secondary air pipe.

In order to prevent pulverized coal from escaping out of the furnace, the secondary air pressure is slightly higher than the primary air pressure (about 100mmHg).

There are three air outlets on the upper part of the furnace, which is convenient for operation and observation, and can inhale air oxidized metal vapor.

Fuming Furnace Operational

In order to achieve good results in the fuming process, the following conditions must be well controlled:temperature, fuel and air supply volume, slag composition, molten pool depth.

1. Temperature

If the temperature is too high (such as exceeding 1350°C), iron deposits or Zn-Fe, Sn-Fe alloys may be formed, which is harmful to the fuming operation. If the temperature is too low, the reduction rate of metal oxides will slow down, the volatilization rate will decrease, the fluidity of the slag will deteriorate, and there may even be a danger of furnace formation, so the temperature in the fuming practice is kept in the range of 1150-1300 °C.

2. Fuel and air supply volume

The most active factor affecting the volatilization rate in the fuming process is the air supply volume. Because the temperature in the furnace, the ratio of CO/CO2, the amount of gas, and the vapor pressure of the metal are all related to the air supply volume. The volume of the air supply depends on the pulverized coal consumption and the air utilization coefficient (α). The larger the air utilization coefficient, the higher the thermal effect of the fuel, the greater the partial pressure of CO2, and the higher the temperature in the furnace; the smaller the air utilization coefficient, the thermal effect is reduced, the partial pressure of CO becomes larger, and the reducing ability is enhanced.

Pulverized coal is both a reducing agent and an exothermic agent in the fuming process, so the CO/CO2 should have an appropriate ratio during combustion. The air utilization factor actually adopted by the factory is variable. Usually, at the beginning of fuming, an air utilization factor close to 1.0 causes almost all carbon to be burned into CO2 to increase the temperature of the slag. In the reduction stage, adjust the air utilization factor to make carbon into CO as much as possible to improve the reduction ability.

3. Slag composition

In practical the actual zinc content of the slag feed into the fuming furnace should be >6%. Below 4%, fuming treatment is uneconomical.

Regarding the effect of slag composition on the volatilization rate of zinc, it can be summarized as follows:

The increase of CaO content can increase the volatilization rate of zinc;

The increase of FeO content in slag has little effect on ZnO activity;

The content of SiO2 increases, and the volatilization rate of zinc decreases. Therefore, the silicic acidity of the slag is preferably in the range of 1.1 to 1.2.

4. Molten pool depth

The thickness of the slag layer in production is generally in the range of 700-1000mm above the tuyere area.

Company Contact:

Contact Name: Liu Wei

Company Name: Hunan Re Technology Co., Ltd

Email:

Tel: 18207409461

Fax:

Street Address: Building.10,

Liandong U Valley Industrial Park

Changsha, Hunan 410036

China

Website: https://www.remetalrecycling.com/

Member name: remetalrecycling

Country: China

China

Member Since: 02 April 2025

Total Leads: 4 remetalrecycling Import Export Business Leads

Business focus: Lead Recycling, Refining Furnace, Lead Melting Furnace Solution Provider

Chat:

Verify: Safe Import Export Tips

coal into the slag in the fuming furnace, generate heat and carbon monoxide after combustion, keep the slag at high temperature, and make the compounds and free ZnO and PbO in the slag reduced to Zn and Pb vapors, the vapor will rise to the upper space of the furnace, meet CO2 or inhaled air and oxidize to zinc oxide and lead oxide again, and are collected in the state of soot.

The four walls of the fuming furnace are all composed of water jackets. The lowermost water jacket on the side is provided with a tuyere. The inner wall of the water jacket is welded with Φ16mm and 50mm long pins, and the distance between the nails is 50mm, so that the condensed slag adheres to it and forms slag layer protects the water jacket and reduces heat loss.

There is a slag outlet on the water jacket at the front end of the furnace.

The lower layer of the water jacket and the inclined flue are water-cooled and circulated, and the upper layer of the water jacket is cooled by vaporization.

The tuyere structure adopts a tuyere with a ball valve, and there are two branch pipes. The one near the water jacket is called the primary air coal pipe, and the one outside is the secondary air pipe.

In order to prevent pulverized coal from escaping out of the furnace, the secondary air pressure is slightly higher than the primary air pressure (about 100mmHg).

There are three air outlets on the upper part of the furnace, which is convenient for operation and observation, and can inhale air oxidized metal vapor.

Fuming Furnace Operational

In order to achieve good results in the fuming process, the following conditions must be well controlled:temperature, fuel and air supply volume, slag composition, molten pool depth.

1. Temperature

If the temperature is too high (such as exceeding 1350°C), iron deposits or Zn-Fe, Sn-Fe alloys may be formed, which is harmful to the fuming operation. If the temperature is too low, the reduction rate of metal oxides will slow down, the volatilization rate will decrease, the fluidity of the slag will deteriorate, and there may even be a danger of furnace formation, so the temperature in the fuming practice is kept in the range of 1150-1300 °C.

2. Fuel and air supply volume

The most active factor affecting the volatilization rate in the fuming process is the air supply volume. Because the temperature in the furnace, the ratio of CO/CO2, the amount of gas, and the vapor pressure of the metal are all related to the air supply volume. The volume of the air supply depends on the pulverized coal consumption and the air utilization coefficient (α). The larger the air utilization coefficient, the higher the thermal effect of the fuel, the greater the partial pressure of CO2, and the higher the temperature in the furnace; the smaller the air utilization coefficient, the thermal effect is reduced, the partial pressure of CO becomes larger, and the reducing ability is enhanced.

Pulverized coal is both a reducing agent and an exothermic agent in the fuming process, so the CO/CO2 should have an appropriate ratio during combustion. The air utilization factor actually adopted by the factory is variable. Usually, at the beginning of fuming, an air utilization factor close to 1.0 causes almost all carbon to be burned into CO2 to increase the temperature of the slag. In the reduction stage, adjust the air utilization factor to make carbon into CO as much as possible to improve the reduction ability.

3. Slag composition

In practical the actual zinc content of the slag feed into the fuming furnace should be >6%. Below 4%, fuming treatment is uneconomical.

Regarding the effect of slag composition on the volatilization rate of zinc, it can be summarized as follows:

The increase of CaO content can increase the volatilization rate of zinc;

The increase of FeO content in slag has little effect on ZnO activity;

The content of SiO2 increases, and the volatilization rate of zinc decreases. Therefore, the silicic acidity of the slag is preferably in the range of 1.1 to 1.2.

4. Molten pool depth

The thickness of the slag layer in production is generally in the range of 700-1000mm above the tuyere area.

Company Contact:

Contact Name: Liu Wei

Company Name: Hunan Re Technology Co., Ltd

Email:

Tel: 18207409461

Fax:

Street Address: Building.10,

Liandong U Valley Industrial Park

Changsha, Hunan 410036

China

Website: https://www.remetalrecycling.com/

Member name: remetalrecycling

Country:

Member Since: 02 April 2025

Total Leads: 4 remetalrecycling Import Export Business Leads

Business focus: Lead Recycling, Refining Furnace, Lead Melting Furnace Solution Provider

Chat:

Verify: Safe Import Export Tips

Similar Suppliers And Manufacturers Import Export Trade Leads

Similar Suppliers And Manufacturers Import Export Trade Leads

Arsenic Reduction Furnace - By remetalrecycling - On Wednesday 2 April 2025 2:47 am: furnace and arsenic reduction furnace is widely praised for its high level of environmental protection high level of automation and large treatment....

Arsenic Reduction Furnace - By remetalrecycling - On Wednesday 2 April 2025 2:47 am: furnace and arsenic reduction furnace is widely praised for its high level of environmental protection high level of automation and large treatment.... Low-temperature Pyrolysis Furnace - By remetalrecycling - On Wednesday 2 April 2025 2:46 am: furnace the technology adopts anaerobic pyrolysis to carry out comprehensive recovery avoiding the production of a large number of hazardous substan....

Low-temperature Pyrolysis Furnace - By remetalrecycling - On Wednesday 2 April 2025 2:46 am: furnace the technology adopts anaerobic pyrolysis to carry out comprehensive recovery avoiding the production of a large number of hazardous substan.... High Temperature Muffle Furnace - By alibiota - On Thursday 25 April 2024 2:37 am: furnace can be used for sample pretreatment in analytical chemistry such as ashing combustion and thermal decomposition of inorganic substances th....

High Temperature Muffle Furnace - By alibiota - On Thursday 25 April 2024 2:37 am: furnace can be used for sample pretreatment in analytical chemistry such as ashing combustion and thermal decomposition of inorganic substances th.... Fluorine-lining Sintering Furnace - By Babyyanfree1 - On Wednesday 7 May 2008 5:53 am: furnace is for manufacturing of fluorine lining for antiseptic valve pipe pipe fitting and chemical device s reaction boiler and others

feature....

Fluorine-lining Sintering Furnace - By Babyyanfree1 - On Wednesday 7 May 2008 5:53 am: furnace is for manufacturing of fluorine lining for antiseptic valve pipe pipe fitting and chemical device s reaction boiler and others

feature.... Smart Spray Coating Furnace - By Babyyanfree1 - On Wednesday 7 May 2008 5:56 am: furnace for the spray coating of static fluorine powder and fluorine paint

features of rfp series as follows

1 this series fluorine-lining si....

Smart Spray Coating Furnace - By Babyyanfree1 - On Wednesday 7 May 2008 5:56 am: furnace for the spray coating of static fluorine powder and fluorine paint

features of rfp series as follows

1 this series fluorine-lining si.... Sell Fuel Oil / Furnace Oil - By Sunimpexfze - On Thursday 15 May 2008 10:39 am: furnace oil it is widely used in industries uses of furnace oil or fuel oil

- used as an industrial fuel furnace oil fo is a dark viscous resi....

Sell Fuel Oil / Furnace Oil - By Sunimpexfze - On Thursday 15 May 2008 10:39 am: furnace oil it is widely used in industries uses of furnace oil or fuel oil

- used as an industrial fuel furnace oil fo is a dark viscous resi.... Rotary Calcining Furnace - By Diyuan - On Wednesday 15 October 2008 12:36 am: furnaces powder metallurgy furnaces annealing furnace powder reduction furnace dewaxing furnace sintering furnace rotary-hearth furnace muffle furn....

Rotary Calcining Furnace - By Diyuan - On Wednesday 15 October 2008 12:36 am: furnaces powder metallurgy furnaces annealing furnace powder reduction furnace dewaxing furnace sintering furnace rotary-hearth furnace muffle furn.... Recycling of metal Classification Navigation

Recycling of metal Classification Navigation

Main - Industrial Cleaning Services - Refuse disposal and treatment - Recycling services - Recycling of metal [18]

TradersCity.com shall not be held liable for any user posted/submitted content including but not limited to trade leads, profiles, images, and any other data. TradersCity.com does not and did not verify any of users posted/submitted data nor is implicitly or explicitly recommending these business offers. TradersCity does not verify truthfulness, accuracy, completeness, nor legality of any businesses, services, and leads posted here. TradersCity does not represent Sellers or Buyers in any transaction between users of the website and is unable to make any opinion in regard to their performance in any transaction. TradersCity neither guarantees nor undertakes in any dispute between sellers and buyers. Protect your business from fraud by trading safely