A free import export trade leads B2B marketplace since 1996 for manufacturers, suppliers, exporters, importers, buyers, sellers, wholesalers, freight forwarders, shippers, trade shows, exhibits, and export management.

Hello visitor from USA - 148 visiting from

USA - 148 visiting from  142 USA

142 USA  4 Singapore

4 Singapore  1 Sweden

1 Sweden  1 UK

1 UK

Hello visitor from

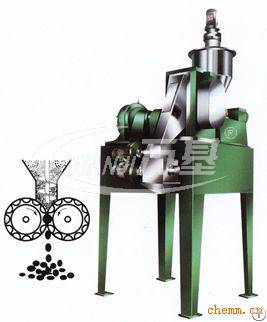

Gzl Series Dry Roller Pressing Granulator

Posted at: Offers to Sell and Export | Posted on: Monday 7 October 2013 2:47 am | Poster last visit: Friday 18 July 2014 |

Product Category: Main

» Industrial Manufacturing and Processing Machinery and Accessories

» Industrial process machinery and equipment and supplies

» Pharmaceutical industry machinery and equipment and supplies

» Granulators

» Gzl Series Dry Roller Pressing Granulator

Product Description:

Description:

This equipment adopts the technology of dry roll-extruding, the powder content moisture

(<10%) is compressed to sheet. then through the technique of fragmentized, sieving, the sheet material become lump, and reach the operating request.

The equipment is based on pressing from the outside and force material pass through two counter-rotating rollers, when rolling the actual density of material increases 1.5-3 times, thus reach the requirement of strength.

Features:

1. Material is compressed by force, doesn't add any humectant, the purity of the products gets the assurance.

2. Dry powder is granulated directly, needn't dry process, more favorable to the connection and transformation of existing process.

3. The strength of the granule is high, the enhance of bulk specific is more obvious than the other model of granulator, especially suitable for the product that need increase the bulk specific gravity.

4. It can control environmental pollution, reduce the powder wasting and the cost of packet, increase the capacity of transport.

5. Structure is compact, maintenance is convenient, operation is easy, technological process is short, energy and fault rate is low, efficiency is high, the application is wide and pressure of the roller can be adjusted freely according to the need.

6. The device of feeding adopt frequency conversion and infinitely variable adjustment, degree of automation is high, can achieve the purpose of multi-machine is controlled by one person, labor intensity is low and can running continuous.

7. The part of main transmission adopts the high quality alloy material, stainless steel, titanium products, chrome and other surface alloy, it improved abrasion resistant, corrosion proof, high temperature resistant and pressure ability greatly, make the machine durable in use.

Principle:

All kinds of dry starch are supplied from the top of the equipment, the material enters into two parallel rollers. After degassing and sprial pressing, the material is forced into the two rollers and is compressed by the two counter-rotating rollers, the surface tension and gravity of material make it deviate from the slot maturely after passing through compression area. The strip material which enters into pulverizer is crashed by rotary knife, the rotating knife of coordinated machine make material enter into vibrating sieve. After sieving, qualified products are sent into material storehouse through conveyor, unqualified products are sent into material storehouse and will be rolled again through conveyor. The size of pushing strength can be adjusted by the hydraulic pressure cylinder according to the need.

Through changing the form of slot on the roller can get the slice, strip, flat material.

Typical Raw Materials:

Granular Capsule Bleaching Agent Inorganic Salts Fertilizer

Catalyst Pigment Pesticide Chlorine Different Cyanogen Urea

White Carbon Black Strontium Carbonate Scour Oxide

Industry Retrieves the dust supplies

Powder of Iron Foundry Aluminium Dust Filtrated Dust

Lead, Zinc Dust of the Converter Grinding Dust

Optional Information

- Payment : T/T

- Delivery : One to Two Month

- Origin : Jiangsu, China

- Minimum Order : 1

- Packaging : Wooden Case

- Samples : Not Available

Company Contact:

Contact Name: Macy Gao

Company Name: Changzhou Wanji Drying & Granulating Equipment Co., Ltd

Email:

Tel: +86-519-88910006

Fax: +86-519-88902866

Street Address: Jiaoxi Town

Changzhou, Jiangsu 213116

China

Member name: WanjiEnterprise

Country: China

China

Member Since: 05 October 2013

Total Leads: 58 WanjiEnterprise Import Export Business Leads

Business focus: Dryer, Granulator, Mixer, Grinder

Chat:

Verify: Safe Import Export Tips

This equipment adopts the technology of dry roll-extruding, the powder content moisture

(<10%) is compressed to sheet. then through the technique of fragmentized, sieving, the sheet material become lump, and reach the operating request.

The equipment is based on pressing from the outside and force material pass through two counter-rotating rollers, when rolling the actual density of material increases 1.5-3 times, thus reach the requirement of strength.

Features:

1. Material is compressed by force, doesn't add any humectant, the purity of the products gets the assurance.

2. Dry powder is granulated directly, needn't dry process, more favorable to the connection and transformation of existing process.

3. The strength of the granule is high, the enhance of bulk specific is more obvious than the other model of granulator, especially suitable for the product that need increase the bulk specific gravity.

4. It can control environmental pollution, reduce the powder wasting and the cost of packet, increase the capacity of transport.

5. Structure is compact, maintenance is convenient, operation is easy, technological process is short, energy and fault rate is low, efficiency is high, the application is wide and pressure of the roller can be adjusted freely according to the need.

6. The device of feeding adopt frequency conversion and infinitely variable adjustment, degree of automation is high, can achieve the purpose of multi-machine is controlled by one person, labor intensity is low and can running continuous.

7. The part of main transmission adopts the high quality alloy material, stainless steel, titanium products, chrome and other surface alloy, it improved abrasion resistant, corrosion proof, high temperature resistant and pressure ability greatly, make the machine durable in use.

Principle:

All kinds of dry starch are supplied from the top of the equipment, the material enters into two parallel rollers. After degassing and sprial pressing, the material is forced into the two rollers and is compressed by the two counter-rotating rollers, the surface tension and gravity of material make it deviate from the slot maturely after passing through compression area. The strip material which enters into pulverizer is crashed by rotary knife, the rotating knife of coordinated machine make material enter into vibrating sieve. After sieving, qualified products are sent into material storehouse through conveyor, unqualified products are sent into material storehouse and will be rolled again through conveyor. The size of pushing strength can be adjusted by the hydraulic pressure cylinder according to the need.

Through changing the form of slot on the roller can get the slice, strip, flat material.

Typical Raw Materials:

Granular Capsule Bleaching Agent Inorganic Salts Fertilizer

Catalyst Pigment Pesticide Chlorine Different Cyanogen Urea

White Carbon Black Strontium Carbonate Scour Oxide

Industry Retrieves the dust supplies

Powder of Iron Foundry Aluminium Dust Filtrated Dust

Lead, Zinc Dust of the Converter Grinding Dust

Optional Information

- Payment : T/T

- Delivery : One to Two Month

- Origin : Jiangsu, China

- Minimum Order : 1

- Packaging : Wooden Case

- Samples : Not Available

Company Contact:

Contact Name: Macy Gao

Company Name: Changzhou Wanji Drying & Granulating Equipment Co., Ltd

Email:

Tel: +86-519-88910006

Fax: +86-519-88902866

Street Address: Jiaoxi Town

Changzhou, Jiangsu 213116

China

Member name: WanjiEnterprise

Country:

Member Since: 05 October 2013

Total Leads: 58 WanjiEnterprise Import Export Business Leads

Business focus: Dryer, Granulator, Mixer, Grinder

Chat:

Verify: Safe Import Export Tips

Similar Suppliers And Manufacturers Import Export Trade Leads

Similar Suppliers And Manufacturers Import Export Trade Leads

Hydraulic Roller Granulator - By fertilizerproductionline - On Saturday 17 September 2022 9:17 am: dry rolling granulation technology to compress the powdery materials with water content amp #8804 5% into flakes or blocks so as to meet the granul....

Hydraulic Roller Granulator - By fertilizerproductionline - On Saturday 17 September 2022 9:17 am: dry rolling granulation technology to compress the powdery materials with water content amp #8804 5% into flakes or blocks so as to meet the granul.... Hydraulic Roller Granulator - By tiancimachine - On Thursday 8 September 2022 3:41 am: granulator equipment manufacturing and the meticulous manufacture of high quality anticorrosion and wear-resistant materials with beautiful appearan....

Hydraulic Roller Granulator - By tiancimachine - On Thursday 8 September 2022 3:41 am: granulator equipment manufacturing and the meticulous manufacture of high quality anticorrosion and wear-resistant materials with beautiful appearan.... Roller Press Granulator - By zhengzhouhuaqiang - On Tuesday 6 September 2022 7:45 am: granulator the dzj-ii machine not only has the above characteristics but also has the updated frame part has also been upgraded the bearing frame i....

Roller Press Granulator - By zhengzhouhuaqiang - On Tuesday 6 September 2022 7:45 am: granulator the dzj-ii machine not only has the above characteristics but also has the updated frame part has also been upgraded the bearing frame i.... Double Roller Press Granulator - By tiancimachine - On Tuesday 6 September 2022 6:10 am: roller press granulator belong to the extrusion slip model its working principle is the motor drive the belt and pulley transfer to the drive shaf....

Double Roller Press Granulator - By tiancimachine - On Tuesday 6 September 2022 6:10 am: roller press granulator belong to the extrusion slip model its working principle is the motor drive the belt and pulley transfer to the drive shaf.... Double Roller Press Granulator - By fertilizerproductionline - On Tuesday 6 September 2022 9:07 am: roller press granulator is a new designed fertilizer equipment by our company based on the double roller fertilizer granulator machine the fertilizer....

Double Roller Press Granulator - By fertilizerproductionline - On Tuesday 6 September 2022 9:07 am: roller press granulator is a new designed fertilizer equipment by our company based on the double roller fertilizer granulator machine the fertilizer.... Six Advantages Of Double Roller Granulator - By tianci - On Thursday 9 February 2023 6:36 am: roller granulator granulates at room temperature without excessive pretreatment of raw materials

2 the double roller granulator is easy to use and....

Six Advantages Of Double Roller Granulator - By tianci - On Thursday 9 February 2023 6:36 am: roller granulator granulates at room temperature without excessive pretreatment of raw materials

2 the double roller granulator is easy to use and.... Reasons For Sticking Rolls Of Double Roller Granulator - By tianci - On Thursday 9 February 2023 6:40 am: roller granulator will inevitably encounter various problems during use the most troublesome thing is that the material sticks to the roll during the....

Reasons For Sticking Rolls Of Double Roller Granulator - By tianci - On Thursday 9 February 2023 6:40 am: roller granulator will inevitably encounter various problems during use the most troublesome thing is that the material sticks to the roll during the.... Disc Granulator Pan Granulator - By fertilizerproductionline - On Tuesday 6 September 2022 9:11 am: granulator machine is our star fertilizer machine and it is used to produce compound fertilizer disc granulator is the most common equipment for orga....

Disc Granulator Pan Granulator - By fertilizerproductionline - On Tuesday 6 September 2022 9:11 am: granulator machine is our star fertilizer machine and it is used to produce compound fertilizer disc granulator is the most common equipment for orga.... Import Export Startup Stories

Import Export Startup Stories

Share Your Story & Get Listed at StartImportExport.com- Zhangjiagang Yuanfeng Plastic Machinery CO Ltd: Nita Liang Of Zhangjiagang Yuanfeng Plastic Machinery Company From China

- Shijiazhuang Goldrain I E Co Ltd: Candy Liu Of Shijiazhuang Goldrain Flour Mill And Silo From China

Granulators Classification Navigation

Granulators Classification Navigation

Main - Industrial Manufacturing and Processing Machinery and Accessories - Industrial process machinery and equipment and supplies - Pharmaceutical industry machinery and equipment and supplies - Granulators [107]

TradersCity.com shall not be held liable for any user posted/submitted content including but not limited to trade leads, profiles, images, and any other data. TradersCity.com does not and did not verify any of users posted/submitted data nor is implicitly or explicitly recommending these business offers. TradersCity does not verify truthfulness, accuracy, completeness, nor legality of any businesses, services, and leads posted here. TradersCity does not represent Sellers or Buyers in any transaction between users of the website and is unable to make any opinion in regard to their performance in any transaction. TradersCity neither guarantees nor undertakes in any dispute between sellers and buyers. Protect your business from fraud by trading safely