A free import export trade leads B2B marketplace since 1996 for manufacturers, suppliers, exporters, importers, buyers, sellers, wholesalers, freight forwarders, shippers, trade shows, exhibits, and export management.

Hello visitor from USA - 196 visiting from

USA - 196 visiting from  167 USA

167 USA  6 France

6 France  5 Singapore

5 Singapore  4 Belgium

4 Belgium  2 UK

2 UK  2 Hong Kong

2 Hong Kong  2 Brazil

2 Brazil  1 Europe

1 Europe  1 Argentina

1 Argentina  1 Tunisia

1 Tunisia  1 Morocco

1 Morocco  1 Canada

1 Canada  1 Uzbekistan

1 Uzbekistan  1 Oman

1 Oman  1 Ecuador

1 Ecuador

Hello visitor from

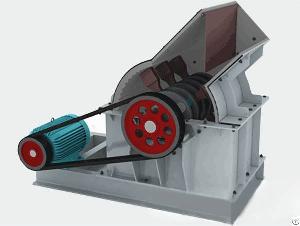

Hammer Crusher Manufacturer In China, Rock Pulverizer, Small Hammer Crusher On Sale At Factory Price

Posted at: Offers to Sell and Export | Posted on: Thursday 6 August 2020 6:02 am | Poster last visit: Thursday 6 August 2020 |

Product Category: Main

» Mining and Well Drilling Machinery and Accessories

» Mining and quarrying machinery and equipment

» Crushers and breakers and grinders

» Crusher hammer

» Hammer Crusher Manufacturer In China, Rock Pulverizer, Small Hammer Crusher On Sale At Factory Price

Product Description:

Hammer crusher manufacturer in China, rock crusher, Small hammer crusher on sale at factory price

Want

to find a hammer crusher for your business? Do you care about quality and service?

We Fier Machinery as a big professional crushing manufacture, our hammer crusher is Equivalent to two crusher reasonable combinations into one.

The efficiency is higher, the quality of the materials is higher, but our hammer crusher price is lower.

Not only the price and quality are superior, but also we can supply you with the one-stop turn-key solution for your hammer crusher order.

Don’t hesitate, Ask your free quote now!

Description of Fier Hammer crusher

Fier hammer crusher as know a doubler stage crusher, It is a new type of Jaw Crusher.

Our hammer mill crusher has overcome the defect that the material is not easy to discharge due to the large bonded grate bottom with water content.

FIER heavy hammer crusher has the advantages of high production efficiency and good crushing effect, etc.

Our machine is suitable for crushing materials such as calcite, limestone, cinder, slag, shale, gangue, construction waste, construction waste, etc.

It solves the problem of using gangue and cinder as additive and internal fuel in brick factories. The problem of high wet material crushing of standard brick and hollow brick produced by gangue and shale.

Fier hammer crusher working principle

when our impact crusher working under driven by two motors

Two sets of rotors connected to each other rotate at high speed at the same time, The material is broken in the machine cavity by the higher rotor and is immediately broken again by the hammerhead of the rapidly rotating lower rotor.

The materials in the inner cavity collide with each other at a high speed and break each other to achieve the effect of hammer powder and powder.

The cinder particles with a particle size of less than 3 mm were formed. To be able to meet your different needs.

Fier hammer crusher design features:

1. The upper and lower stages of the double rotors are crushed — two sets of rotors are connected to each other

so that the materials smashed by the superior rotor are immediately broken again by the hammerhead of the rapidly rotating lower rotor.

The inner cavity materials collide with each other rapidly, when each other is broken, to achieve the effect of hammer powder, powder, direct discharge.

2, there is no sieve bottom, high wet material, never block.

The traditional crusher with a grate sieve plate is not suitable for the raw material whose moisture content is higher than 8%.

When the moisture content of raw material is higher than 10%, the serious blockage is easy to occur.

It makes the hammerhead unable to rotate, material unable to discharge, and even burns out the motor, seriously affecting production.

Our swing hammer crusher does not need the bottom of the sieve net, there is no strict requirement on the moisture content of the material, there is no problem of plugging the sieve plate.

The water content of the feed can reach 100%, the fineness of the discharge 90% is all in 2MM (less than mm), 1MM (less than mm) accounts for 70%, both dry and wet, production as usual in rainy days.

Moreover, there is no problem that fine powder cannot be discharged in time and repeatedly crushed, so the crushing efficiency is high and there is no ineffective wear phenomenon of a hammerhead.

3, double rotor two pieces of grinding, the yield is large, the granularity of output is 3 mm less than, 2 mm less than 80%.

4. Wear-resistant combination hammerhead — high alloy wear-resistant hammerhead. Hammerhead hammer handle is used in combination, only the hammerhead is changed, not the hammer handle.

5. Unique shift gap adjustment technology — no repair is needed after the hammerhead is worn, and the moving position can be used repeatedly. One set of hammerheads can be used against three sets of hammerheads.

6. Hydraulic electric starting case — it can be opened and closed easily by only one person, which is not only light, fast, safe, and reliable, but also easy to maintain.

Special advantages of Fier Hammer Crusher

Simple operation, convenient installation and maintenance

Electric – hydraulic control, one person can easily complete the operation, maintenance, replacement parts

Uniform grain size and high yield

The output particle size is uniform, it can crush more than 20 tons of material per hour, and the cost of crushing coal cinder per ton does not exceed 0.25 USD

Wear parts have a long service life

The machine adopts high alloy wear-resisting hammerhead, which reduces the time of material staying in the crushing chamber, and thus improves the service life of the vulnerable parts

High utilization rate of hammerhead hammer crusher wear parts

Unique shift gap adjustment technology, no need to repair the worn hammerhead, the moving position is used repeatedly, one set of hammerhead can be used against three sets of hammerhead

Choice us

“Customer success” is what we strive for.

We seek success as much as you do. The more profit you earn, the more reputation we earn. Win-win situation!

Your satisfaction is our success! This is how we do business. We are not just selling products, we are selling you a brighter and greener future!

We FIER Machinery can give your best solution for your hammer crusher order.

It would be appreciated if you could contact us at any time. We will reply in 24 hours.

Company Contact:

Contact Name: Maxwell Wang

Company Name: Henan Fier Machinery Co., Ltd

Email:

Tel: +86 15716513255

Fax: +86-0371-67118166

Street Address: No.514 Zhengshuang

Huidu Center , Zhengzhou City, Henan

China Zhengzhou, Zhengzhou City

45000 China

Other Contact Info:

Mobile/whatsapp/wechat: +86 15716513255

Skype:

Website: https://fierchina.com

Member name: FierMachienry

Country: China

China

Member Since: 05 August 2020

Total Leads: 8 FierMachienry Import Export Business Leads

Business focus: Crushing Machines, Mixing Machines, Packing Machine, Drying Room

Chat:

Verify: Safe Import Export Tips

Want

to find a hammer crusher for your business? Do you care about quality and service?

We Fier Machinery as a big professional crushing manufacture, our hammer crusher is Equivalent to two crusher reasonable combinations into one.

The efficiency is higher, the quality of the materials is higher, but our hammer crusher price is lower.

Not only the price and quality are superior, but also we can supply you with the one-stop turn-key solution for your hammer crusher order.

Don’t hesitate, Ask your free quote now!

Description of Fier Hammer crusher

Fier hammer crusher as know a doubler stage crusher, It is a new type of Jaw Crusher.

Our hammer mill crusher has overcome the defect that the material is not easy to discharge due to the large bonded grate bottom with water content.

FIER heavy hammer crusher has the advantages of high production efficiency and good crushing effect, etc.

Our machine is suitable for crushing materials such as calcite, limestone, cinder, slag, shale, gangue, construction waste, construction waste, etc.

It solves the problem of using gangue and cinder as additive and internal fuel in brick factories. The problem of high wet material crushing of standard brick and hollow brick produced by gangue and shale.

Fier hammer crusher working principle

when our impact crusher working under driven by two motors

Two sets of rotors connected to each other rotate at high speed at the same time, The material is broken in the machine cavity by the higher rotor and is immediately broken again by the hammerhead of the rapidly rotating lower rotor.

The materials in the inner cavity collide with each other at a high speed and break each other to achieve the effect of hammer powder and powder.

The cinder particles with a particle size of less than 3 mm were formed. To be able to meet your different needs.

Fier hammer crusher design features:

1. The upper and lower stages of the double rotors are crushed — two sets of rotors are connected to each other

so that the materials smashed by the superior rotor are immediately broken again by the hammerhead of the rapidly rotating lower rotor.

The inner cavity materials collide with each other rapidly, when each other is broken, to achieve the effect of hammer powder, powder, direct discharge.

2, there is no sieve bottom, high wet material, never block.

The traditional crusher with a grate sieve plate is not suitable for the raw material whose moisture content is higher than 8%.

When the moisture content of raw material is higher than 10%, the serious blockage is easy to occur.

It makes the hammerhead unable to rotate, material unable to discharge, and even burns out the motor, seriously affecting production.

Our swing hammer crusher does not need the bottom of the sieve net, there is no strict requirement on the moisture content of the material, there is no problem of plugging the sieve plate.

The water content of the feed can reach 100%, the fineness of the discharge 90% is all in 2MM (less than mm), 1MM (less than mm) accounts for 70%, both dry and wet, production as usual in rainy days.

Moreover, there is no problem that fine powder cannot be discharged in time and repeatedly crushed, so the crushing efficiency is high and there is no ineffective wear phenomenon of a hammerhead.

3, double rotor two pieces of grinding, the yield is large, the granularity of output is 3 mm less than, 2 mm less than 80%.

4. Wear-resistant combination hammerhead — high alloy wear-resistant hammerhead. Hammerhead hammer handle is used in combination, only the hammerhead is changed, not the hammer handle.

5. Unique shift gap adjustment technology — no repair is needed after the hammerhead is worn, and the moving position can be used repeatedly. One set of hammerheads can be used against three sets of hammerheads.

6. Hydraulic electric starting case — it can be opened and closed easily by only one person, which is not only light, fast, safe, and reliable, but also easy to maintain.

Special advantages of Fier Hammer Crusher

Simple operation, convenient installation and maintenance

Electric – hydraulic control, one person can easily complete the operation, maintenance, replacement parts

Uniform grain size and high yield

The output particle size is uniform, it can crush more than 20 tons of material per hour, and the cost of crushing coal cinder per ton does not exceed 0.25 USD

Wear parts have a long service life

The machine adopts high alloy wear-resisting hammerhead, which reduces the time of material staying in the crushing chamber, and thus improves the service life of the vulnerable parts

High utilization rate of hammerhead hammer crusher wear parts

Unique shift gap adjustment technology, no need to repair the worn hammerhead, the moving position is used repeatedly, one set of hammerhead can be used against three sets of hammerhead

Choice us

“Customer success” is what we strive for.

We seek success as much as you do. The more profit you earn, the more reputation we earn. Win-win situation!

Your satisfaction is our success! This is how we do business. We are not just selling products, we are selling you a brighter and greener future!

We FIER Machinery can give your best solution for your hammer crusher order.

It would be appreciated if you could contact us at any time. We will reply in 24 hours.

Company Contact:

Contact Name: Maxwell Wang

Company Name: Henan Fier Machinery Co., Ltd

Email:

Tel: +86 15716513255

Fax: +86-0371-67118166

Street Address: No.514 Zhengshuang

Huidu Center , Zhengzhou City, Henan

China Zhengzhou, Zhengzhou City

45000 China

Other Contact Info:

Mobile/whatsapp/wechat: +86 15716513255

Skype:

Website: https://fierchina.com

Member name: FierMachienry

Country:

Member Since: 05 August 2020

Total Leads: 8 FierMachienry Import Export Business Leads

Business focus: Crushing Machines, Mixing Machines, Packing Machine, Drying Room

Chat:

Verify: Safe Import Export Tips

Similar Suppliers And Manufacturers Import Export Trade Leads

Similar Suppliers And Manufacturers Import Export Trade Leads

Rock Crusher - By SBM - On Friday 9 June 2023 1:27 am: hammer crusher a hammer crusher often called a hammer mill is a machine that crushes materials by impacting them with revolving hammers soft to me....

Rock Crusher - By SBM - On Friday 9 June 2023 1:27 am: hammer crusher a hammer crusher often called a hammer mill is a machine that crushes materials by impacting them with revolving hammers soft to me.... Maize Flour Milling Machine With Hammer Crusher - By pinglemachine - On Friday 18 August 2023 4:44 am: crusher with long life time

4 self-absorption percusion grinder integrates loading crushing and discharging which saves investment

maize flour mil....

Maize Flour Milling Machine With Hammer Crusher - By pinglemachine - On Friday 18 August 2023 4:44 am: crusher with long life time

4 self-absorption percusion grinder integrates loading crushing and discharging which saves investment

maize flour mil.... Jaw Crusher Pulley Crusher Wheel Customize According To Drawing - By zoeyguo - On Tuesday 31 May 2022 3:23 am: crusher spare part

note we can also manufacture other ferrous amp amp non-ferrous mechanical spares

as per customer’s drawings amp amp specific....

Jaw Crusher Pulley Crusher Wheel Customize According To Drawing - By zoeyguo - On Tuesday 31 May 2022 3:23 am: crusher spare part

note we can also manufacture other ferrous amp amp non-ferrous mechanical spares

as per customer’s drawings amp amp specific.... Dm100a Pneumatic Powered Rock Drilling Rig - By jcdrill - On Tuesday 10 May 2022 3:05 am: rock drilling rig

the rock blasting drilling rig dm100a b is high powered with easy operation system the pneumatic drill could be applied in open mi....

Dm100a Pneumatic Powered Rock Drilling Rig - By jcdrill - On Tuesday 10 May 2022 3:05 am: rock drilling rig

the rock blasting drilling rig dm100a b is high powered with easy operation system the pneumatic drill could be applied in open mi.... Cage Crusher - By zhengzhouhuaqiang - On Saturday 17 September 2022 7:50 am: crusher belongs to medium-sized horizontal cage mill it can crush all kinds of single chemical fertilizers with water content below 6% especially fo....

Cage Crusher - By zhengzhouhuaqiang - On Saturday 17 September 2022 7:50 am: crusher belongs to medium-sized horizontal cage mill it can crush all kinds of single chemical fertilizers with water content below 6% especially fo.... Chain Crusher - By tianci - On Thursday 8 September 2022 7:17 am: crusher is applied to the shattering of the block in the production of organic fertilizer also it is widely used in chemical industry building mate....

Chain Crusher - By tianci - On Thursday 8 September 2022 7:17 am: crusher is applied to the shattering of the block in the production of organic fertilizer also it is widely used in chemical industry building mate.... Straw Crusher - By fertilizerproductionline - On Wednesday 21 September 2022 9:09 am: crusher is mainly used for chopping processing of plant straws such as crop straws and branches with a diameter of 5 cm or less nd can also be used f....

Straw Crusher - By fertilizerproductionline - On Wednesday 21 September 2022 9:09 am: crusher is mainly used for chopping processing of plant straws such as crop straws and branches with a diameter of 5 cm or less nd can also be used f.... Straw Crusher - By tiancimachine - On Thursday 15 September 2022 6:36 am: crusher can crush corn straw straw peanut skin beanstalk flowers and other burning residues it avoided the burning of crop straw protected the e....

Straw Crusher - By tiancimachine - On Thursday 15 September 2022 6:36 am: crusher can crush corn straw straw peanut skin beanstalk flowers and other burning residues it avoided the burning of crop straw protected the e.... Import Export Startup Stories

Import Export Startup Stories

Share Your Story & Get Listed at StartImportExport.com- SpecsPro LLC: Cathy Huang Of SpecsPro LLC Integrated Sourcing Supply Chain Solutions From USA

- Alfa Sourcing International Co Ltd: Nancy Of Alfa Sourcing International Helping Provide Purchasing Expertise And Services From China

- Winfys Group Inc: Andy Xiong Of Winfys Group A Dongle Manufacturer From China

- China Nanchang Rising Sun Import and Export Corporation : Jackson Yu Of China Nanchang Rising Sun Supplying Overstock Garment

- Tianjin Shengjintai Steel and Iron Co Ltd: Eire Guo Of Tianjin Shengjintai Steel and Iron From China

Crusher hammer Classification Navigation

Crusher hammer Classification Navigation

Main - Mining and Well Drilling Machinery and Accessories - Mining and quarrying machinery and equipment - Crushers and breakers and grinders - Crusher hammer [53]

TradersCity.com shall not be held liable for any user posted/submitted content including but not limited to trade leads, profiles, images, and any other data. TradersCity.com does not and did not verify any of users posted/submitted data nor is implicitly or explicitly recommending these business offers. TradersCity does not verify truthfulness, accuracy, completeness, nor legality of any businesses, services, and leads posted here. TradersCity does not represent Sellers or Buyers in any transaction between users of the website and is unable to make any opinion in regard to their performance in any transaction. TradersCity neither guarantees nor undertakes in any dispute between sellers and buyers. Protect your business from fraud by trading safely