A free import export trade leads B2B marketplace since 1996 for manufacturers, suppliers, exporters, importers, buyers, sellers, wholesalers, freight forwarders, shippers, trade shows, exhibits, and export management.

Hello visitor from USA - 62 visiting from

USA - 62 visiting from  27 USA

27 USA  12 Germany

12 Germany  12 Canada

12 Canada  3 Belgium

3 Belgium  2 Brazil

2 Brazil  2 France

2 France  1 Iran

1 Iran  1 Singapore

1 Singapore  1 UK

1 UK  1 Czech Republic

1 Czech Republic

Hello visitor from

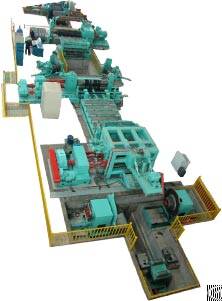

Heavy Gauge Cut To Length Lines

Posted at: Offers to Sell and Export | Posted on: Tuesday 4 December 2018 4:39 am | Poster last visit: Thursday 6 December 2018 |

Product Category: Main

» Industrial Manufacturing and Processing Machinery and Accessories

» Raw materials processing machinery

» Machinery for working wood and stone and ceramic and the like

» Milling machines

» Heavy Gauge Cut To Length Lines

Product Description:

Cut To Length line is a high efficient metal processing production line for cutting metal flat sheet

from metal coils. The metal coils unwind, leveled, cut to length and blanking. RISHBIN supply full range of cut to length line China according to client’s special requirement by combining different component. Every CTL line is engineered and constructed differently for customers, it is customized designed and built, it is considered when choosing a right CTL line about some specifics like production capacity, running speed, material thickness and width, etc. Quality and standard checks are strictly performed on our product before releasing to our valued customers.

Available raw material for cut to length line is hot rolled steel, cold rolled steel, galvanized steel, pre-painted steel, high tensile steel, stainless steel, aluminum, copper, alloys.

The whole line consists of coil car, double support uncoiler, hydraulic pressing and guiding side device, shovel head, pre-leveler, high precision leveler, cut to length machine, stacker, electric control system, hydraulic system, etc. as well as pendulum middle plate and steering device.

Main Technical Parameters of Heavy Gauge Cut To Length Lines

1.Coil properties: δs≤550MPa, δb≤600MPa

2.Coil thickness: 8mm-25mm

3.Coil width: Max. 2500mm

4.Coil I.D: 508 mm

5.Coil O.D: Max. 2500 mm

6.Coil weight: 40000 kg

7.Line speed: 0-25 m/min

8.Leveler shaft diameter: 260 mm

9.Leveler rollers quantity: 9

10.Cutting length: 800-12000 mm

11.Cutting rate: 8 pieces/min

12.Length tolerance: ±1 mm

13.Diagonal tolerance: ±2 mm

14.Straightening tolerance: ±2 mm/m2

15.Total power: about 250 KW

16.Total weight: about 80 T

RISHBIN heavy gauge cut to length lines are built for speed and ease of use and can produce higher line speeds without experiencing material slippage. Cut-To-Length Line and Blanking Line will make your job easier, cut costs, and increase your profits.

The lines can be supplied with start-stop shears, flying shears. For start stop shear, the sheet is stopped for each cut of the shear. They can cut a variety of lengths and thicknesses. Electric controls are used to stop the leveler drive after the required length has been fed through the shear and to initiate shear action, then the subsequent feeding of the sheared length to the stacker. For flying shear, it’s a high production solution

Here is working process:

Steel coils are transferred by an entry coil car and loaded onto an uncoiler. From uncoiler the strip proceeds through a five-high precision leveler designed to level steel within the desired material gauge range and yield strength. The strip then proceeds through a squaring unit and precision roll-feed unit to the high speed shear, where it is cut to required length. The cut sheet then moves to float sheet stacker where it is stacked on a pallet and is then moved onto the semiautomatic packaging line for wrapping.

Benefits of RISHBIN Cut to Length lines

Minimal tooling preparations and higher productivity rates

Energy efficient

Reduced operating costs

High in speed and strength

High input and output rates

Extreme sheet flatness due to high precision levelers

Exact cutting accuracy

Company Contact:

Contact Name: Chris Ho

Company Name: Rishbin Co., Ltd

Email:

Tel: 051085853379

Fax:

Street Address: Room 702a, No.

787-1, Five Star Garden, Wuxi

Wuxi, Jiangsu 214000

China

Website: http://www.steelslitter.com/

Member name: ChrisHo

Country: China

China

Member Since: 01 December 2018

Total Leads: 5 ChrisHo Import Export Business Leads

Business focus: Roll Forming Machine, Steel Slitting Line, Tube Mill, Pu Sandwich Panel Line

Chat:

Verify: Safe Import Export Tips

from metal coils. The metal coils unwind, leveled, cut to length and blanking. RISHBIN supply full range of cut to length line China according to client’s special requirement by combining different component. Every CTL line is engineered and constructed differently for customers, it is customized designed and built, it is considered when choosing a right CTL line about some specifics like production capacity, running speed, material thickness and width, etc. Quality and standard checks are strictly performed on our product before releasing to our valued customers.

Available raw material for cut to length line is hot rolled steel, cold rolled steel, galvanized steel, pre-painted steel, high tensile steel, stainless steel, aluminum, copper, alloys.

The whole line consists of coil car, double support uncoiler, hydraulic pressing and guiding side device, shovel head, pre-leveler, high precision leveler, cut to length machine, stacker, electric control system, hydraulic system, etc. as well as pendulum middle plate and steering device.

Main Technical Parameters of Heavy Gauge Cut To Length Lines

1.Coil properties: δs≤550MPa, δb≤600MPa

2.Coil thickness: 8mm-25mm

3.Coil width: Max. 2500mm

4.Coil I.D: 508 mm

5.Coil O.D: Max. 2500 mm

6.Coil weight: 40000 kg

7.Line speed: 0-25 m/min

8.Leveler shaft diameter: 260 mm

9.Leveler rollers quantity: 9

10.Cutting length: 800-12000 mm

11.Cutting rate: 8 pieces/min

12.Length tolerance: ±1 mm

13.Diagonal tolerance: ±2 mm

14.Straightening tolerance: ±2 mm/m2

15.Total power: about 250 KW

16.Total weight: about 80 T

RISHBIN heavy gauge cut to length lines are built for speed and ease of use and can produce higher line speeds without experiencing material slippage. Cut-To-Length Line and Blanking Line will make your job easier, cut costs, and increase your profits.

The lines can be supplied with start-stop shears, flying shears. For start stop shear, the sheet is stopped for each cut of the shear. They can cut a variety of lengths and thicknesses. Electric controls are used to stop the leveler drive after the required length has been fed through the shear and to initiate shear action, then the subsequent feeding of the sheared length to the stacker. For flying shear, it’s a high production solution

Here is working process:

Steel coils are transferred by an entry coil car and loaded onto an uncoiler. From uncoiler the strip proceeds through a five-high precision leveler designed to level steel within the desired material gauge range and yield strength. The strip then proceeds through a squaring unit and precision roll-feed unit to the high speed shear, where it is cut to required length. The cut sheet then moves to float sheet stacker where it is stacked on a pallet and is then moved onto the semiautomatic packaging line for wrapping.

Benefits of RISHBIN Cut to Length lines

Minimal tooling preparations and higher productivity rates

Energy efficient

Reduced operating costs

High in speed and strength

High input and output rates

Extreme sheet flatness due to high precision levelers

Exact cutting accuracy

Company Contact:

Contact Name: Chris Ho

Company Name: Rishbin Co., Ltd

Email:

Tel: 051085853379

Fax:

Street Address: Room 702a, No.

787-1, Five Star Garden, Wuxi

Wuxi, Jiangsu 214000

China

Website: http://www.steelslitter.com/

Member name: ChrisHo

Country:

Member Since: 01 December 2018

Total Leads: 5 ChrisHo Import Export Business Leads

Business focus: Roll Forming Machine, Steel Slitting Line, Tube Mill, Pu Sandwich Panel Line

Chat:

Verify: Safe Import Export Tips

Similar Suppliers And Manufacturers Import Export Trade Leads

Similar Suppliers And Manufacturers Import Export Trade Leads

Heavy Duty Spur Gear Slewing Drives S-iii-o-0955 Used For Heavy Equipment - By UniqueTransmission - On Friday 21 October 2022 4:37 am: heavy equipment to drive the workpieces to rotate at a low speed so that the workpieces can reach the designated positions the equipment that requir....

Heavy Duty Spur Gear Slewing Drives S-iii-o-0955 Used For Heavy Equipment - By UniqueTransmission - On Friday 21 October 2022 4:37 am: heavy equipment to drive the workpieces to rotate at a low speed so that the workpieces can reach the designated positions the equipment that requir.... Helical Gear Slewing Drives Specially Designed For Production Workshop Lines - By UniqueTransmission - On Saturday 22 October 2022 3:32 am: lines which are installed and used vertically on the equipment

the slewing drives are responsible for driving the four-station worktables to rotate....

Helical Gear Slewing Drives Specially Designed For Production Workshop Lines - By UniqueTransmission - On Saturday 22 October 2022 3:32 am: lines which are installed and used vertically on the equipment

the slewing drives are responsible for driving the four-station worktables to rotate.... Reflex Gauge Glass - By aohonggaugeglass - On Monday 16 October 2023 8:57 am: gauge glass also named reflex sight glass reflex level gauge glass boiler glass and reflex level gauge

aohong special glass manufacturing co lt....

Reflex Gauge Glass - By aohonggaugeglass - On Monday 16 October 2023 8:57 am: gauge glass also named reflex sight glass reflex level gauge glass boiler glass and reflex level gauge

aohong special glass manufacturing co lt.... Frame Acurate Gauge - By juichihco - On Monday 4 March 2024 7:49 am: gauge is engineered with state-of-the-art technology ensuring unparalleled precision in your measurements whether you are working on bicycle frames ....

Frame Acurate Gauge - By juichihco - On Monday 4 March 2024 7:49 am: gauge is engineered with state-of-the-art technology ensuring unparalleled precision in your measurements whether you are working on bicycle frames .... Ldt-l200 Ladle Lining Laser Thickness Gauge - By WuhanCenterRise - On Wednesday 7 September 2022 3:49 am: gauge

overview

ldt-l200 is a new generation of ladle lining thickness gauge launched by our company the system equipment emits a pulsed laser beam ....

Ldt-l200 Ladle Lining Laser Thickness Gauge - By WuhanCenterRise - On Wednesday 7 September 2022 3:49 am: gauge

overview

ldt-l200 is a new generation of ladle lining thickness gauge launched by our company the system equipment emits a pulsed laser beam .... Nc Cut Off Machine - By HTLida - On Saturday 11 June 2022 1:50 am: cut off machine vailable breadth 1400-2200mm

specification

1 max machine speed 200m min when cutting length is 0 5m speed is 100m min

2 cutting....

Nc Cut Off Machine - By HTLida - On Saturday 11 June 2022 1:50 am: cut off machine vailable breadth 1400-2200mm

specification

1 max machine speed 200m min when cutting length is 0 5m speed is 100m min

2 cutting.... Huatao Nc Cut Off Machine - By HTLida - On Thursday 23 June 2022 1:09 am: cut off machine vailable breadth 1400-2200mm

specification

1 max machine speed 200m min when cutting length is 0 5m speed is 100m min

2 cutting....

Huatao Nc Cut Off Machine - By HTLida - On Thursday 23 June 2022 1:09 am: cut off machine vailable breadth 1400-2200mm

specification

1 max machine speed 200m min when cutting length is 0 5m speed is 100m min

2 cutting.... Straightened Cut Tie Wire - By WireTie - On Friday 10 February 2023 7:27 am: gauge wire 20 22 and 24 gauge cut at least 39”

cut galvanized wire for hanging vines in a commercial greenhouse 13 gauge wire in 34 quot straigh....

Straightened Cut Tie Wire - By WireTie - On Friday 10 February 2023 7:27 am: gauge wire 20 22 and 24 gauge cut at least 39”

cut galvanized wire for hanging vines in a commercial greenhouse 13 gauge wire in 34 quot straigh.... Import Export Startup Stories

Import Export Startup Stories

Share Your Story & Get Listed at StartImportExport.com- Mag Makina imalat: Mustafa Yildiz Of Mag Makina Imalat From Turkey For Marine, Automotive And Heavy Equipment Parts

- Gltak Automobile Germany Co Ltd : Sophie Of GLTAK Automobile Germany, A Heavy Duty Truck Spare Parts Production Company From China

Milling machines Classification Navigation

Milling machines Classification Navigation

Main - Industrial Manufacturing and Processing Machinery and Accessories - Raw materials processing machinery - Machinery for working wood and stone and ceramic and the like - Milling machines [208]

TradersCity.com shall not be held liable for any user posted/submitted content including but not limited to trade leads, profiles, images, and any other data. TradersCity.com does not and did not verify any of users posted/submitted data nor is implicitly or explicitly recommending these business offers. TradersCity does not verify truthfulness, accuracy, completeness, nor legality of any businesses, services, and leads posted here. TradersCity does not represent Sellers or Buyers in any transaction between users of the website and is unable to make any opinion in regard to their performance in any transaction. TradersCity neither guarantees nor undertakes in any dispute between sellers and buyers. Protect your business from fraud by trading safely