A free import export trade leads B2B marketplace since 1996 for manufacturers, suppliers, exporters, importers, buyers, sellers, wholesalers, freight forwarders, shippers, trade shows, exhibits, and export management.

Hello visitor from USA - 67 visiting from

USA - 67 visiting from  25 USA

25 USA  13 Canada

13 Canada  10 Germany

10 Germany  5 Belgium

5 Belgium  3 Czech Republic

3 Czech Republic  3 France

3 France  3 Hong Kong

3 Hong Kong  2 UK

2 UK  1 Ukraine

1 Ukraine  1 Iran

1 Iran  1 China

1 China

Hello visitor from

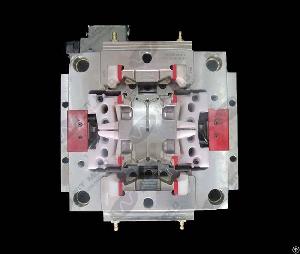

Inserted Molding Tool

Posted at: Offers to Sell and Export | Posted on: Wednesday 10 November 2021 2:05 am | Poster last visit: Wednesday 10 November 2021 |

Product Category: Main

» Manufacturing Components and Supplies

» Moldings

» Inserted injection moldings

» Plastic inserted injection molding

» Inserted Molding Tool

Product Description:

INSERTED MOLDING TOOL insert injection molding plastic injection tool Injection Mold Company

China

What does the manufacturing process look like for insert molding?

Insert molding is the process of molding thermoplastic material around a preformed component (an insert) to create a finished part that incorporates multiple materials. The inserts are typically metal parts that are used to reinforce the mechanical properties of the plastic part. The inserts are placed into the mold and thermoplastic is injected into the mold to form the part. As compared to installing inserts into a plastic part in a post-molding process, the use of molded-in inserts eliminates the need for secondary installation of the inserts and thereby reduces costs.

Tool features:

1. Over-moulding metal

2. Hasco 4200 for seal

Part function: Inserted Molding Tools for BMW automotive products.

Part material: TPU+ metal

Cavity: 2+2 cavties

Insert Injection Molding Benefits

Metal inserts and bushings are commonly used for reinforcing the mechanical properties of the plastic parts or thermoplastic elastomer products that are created through the insert injection molding process. Insert molding provides a number of benefits that will improve your companys processes all the way down to its bottom line. Some of the benefits of insert injection molding, include:

Improves component reliability

Improved strength & structure

Reduces assembly and labor costs

Reduces the size & weight of the part

Enhanced design flexibility

Applications for Insert Injection Molding

Insert molding is used in a broad range of industries for a variety of uses and applications. WIT MOLD primarily focuses on insert injection molding for the following sectors: Medical, Pharmaceutical, Dental, Defense, Safety, Industrial, and Electronics/Electrical.

WIT Mold supply all kinds of molds, such as conventional plastic molds, precision injection molding, unscrewing molds, two shot injection molds etc., and are mainly exported to North America, Europe and other parts of the world.

Company Contact:

Contact Name: Doris Lee

Company Name: Wit Mold

Email:

Tel: 86075586225026

Fax: 86075586225026

Street Address: Room 2304, The East

Building Of Haian Shidai, Shennan

Road #12069, Nanshan District

Shenzhen, China 518106 China

Other Contact Info:

Whatsapp: 8613823293321

Skype: Wit.mold

Website: https://witmold.com

Member name: witmoldltd

Country: China

China

Member Since: 10 November 2021

Total Leads: 10 witmoldltd Import Export Business Leads

Business focus: Precision Molds, Plastic Injection Mould

Chat:

Verify: Safe Import Export Tips

China

What does the manufacturing process look like for insert molding?

Insert molding is the process of molding thermoplastic material around a preformed component (an insert) to create a finished part that incorporates multiple materials. The inserts are typically metal parts that are used to reinforce the mechanical properties of the plastic part. The inserts are placed into the mold and thermoplastic is injected into the mold to form the part. As compared to installing inserts into a plastic part in a post-molding process, the use of molded-in inserts eliminates the need for secondary installation of the inserts and thereby reduces costs.

Tool features:

1. Over-moulding metal

2. Hasco 4200 for seal

Part function: Inserted Molding Tools for BMW automotive products.

Part material: TPU+ metal

Cavity: 2+2 cavties

Insert Injection Molding Benefits

Metal inserts and bushings are commonly used for reinforcing the mechanical properties of the plastic parts or thermoplastic elastomer products that are created through the insert injection molding process. Insert molding provides a number of benefits that will improve your companys processes all the way down to its bottom line. Some of the benefits of insert injection molding, include:

Improves component reliability

Improved strength & structure

Reduces assembly and labor costs

Reduces the size & weight of the part

Enhanced design flexibility

Applications for Insert Injection Molding

Insert molding is used in a broad range of industries for a variety of uses and applications. WIT MOLD primarily focuses on insert injection molding for the following sectors: Medical, Pharmaceutical, Dental, Defense, Safety, Industrial, and Electronics/Electrical.

WIT Mold supply all kinds of molds, such as conventional plastic molds, precision injection molding, unscrewing molds, two shot injection molds etc., and are mainly exported to North America, Europe and other parts of the world.

Company Contact:

Contact Name: Doris Lee

Company Name: Wit Mold

Email:

Tel: 86075586225026

Fax: 86075586225026

Street Address: Room 2304, The East

Building Of Haian Shidai, Shennan

Road #12069, Nanshan District

Shenzhen, China 518106 China

Other Contact Info:

Whatsapp: 8613823293321

Skype: Wit.mold

Website: https://witmold.com

Member name: witmoldltd

Country:

Member Since: 10 November 2021

Total Leads: 10 witmoldltd Import Export Business Leads

Business focus: Precision Molds, Plastic Injection Mould

Chat:

Verify: Safe Import Export Tips

Similar Suppliers And Manufacturers Import Export Trade Leads

Similar Suppliers And Manufacturers Import Export Trade Leads

Pulp Molding Machine - By BestonGroupCo - On Monday 5 September 2022 7:45 am: molding machine industrial packaging machine can make pulp products from waste paper our customers usually use this machine to make egg tray carton b....

Pulp Molding Machine - By BestonGroupCo - On Monday 5 September 2022 7:45 am: molding machine industrial packaging machine can make pulp products from waste paper our customers usually use this machine to make egg tray carton b.... Oem Bush Sintered Mim Metal Molding Part For Motorcycle Spare Parts And Gearbox Parts - By Yujiaxin - On Tuesday 23 January 2024 3:24 am: molding part motorcycle spare parts gearbox parts

we are a precision engineering manufacturer based in south china shenzhen specializing in the suppl....

Oem Bush Sintered Mim Metal Molding Part For Motorcycle Spare Parts And Gearbox Parts - By Yujiaxin - On Tuesday 23 January 2024 3:24 am: molding part motorcycle spare parts gearbox parts

we are a precision engineering manufacturer based in south china shenzhen specializing in the suppl.... F Connector Removal Tool - By stronictool - On Friday 10 June 2022 8:30 am: f connector removal tool

description

model cf8101

f connector removal tool

for security system use

remove f connectors in high density or hard-to-reach locations

mo....

F Connector Removal Tool - By stronictool - On Friday 10 June 2022 8:30 am: f connector removal tool

description

model cf8101

f connector removal tool

for security system use

remove f connectors in high density or hard-to-reach locations

mo.... Sell Grooving Tool Inserts Zthd0504-mg - By xinruico - On Wednesday 15 March 2023 8:15 am: tools our products are of high quality and competitive price

commodity grooving tool inserts zthd0504-mg

1 various grade and size are available....

Sell Grooving Tool Inserts Zthd0504-mg - By xinruico - On Wednesday 15 March 2023 8:15 am: tools our products are of high quality and competitive price

commodity grooving tool inserts zthd0504-mg

1 various grade and size are available.... Network Maintenance Tool Kit 133 Pcs - By stronictool - On Friday 10 June 2022 8:23 am: tool

punch down tool with 66 110 blades

utp cable stripper

rotary coaxial stripper

wire stripper tool

flashlight

rj-45 amp rat....

Network Maintenance Tool Kit 133 Pcs - By stronictool - On Friday 10 June 2022 8:23 am: tool

punch down tool with 66 110 blades

utp cable stripper

rotary coaxial stripper

wire stripper tool

flashlight

rj-45 amp rat.... Anti-static Computer Tool Kit 39 Pcs - By stronictool - On Friday 10 June 2022 8:27 am: anti-static computer tool kit 39 pcs

description

sy-8151 39 pcs

anti-static service pad

reversible ratch handle

bit group

7 pcs hex key

1 5 2 0 2 5 3 0 4 0 5 0 ....

Anti-static Computer Tool Kit 39 Pcs - By stronictool - On Friday 10 June 2022 8:27 am: anti-static computer tool kit 39 pcs

description

sy-8151 39 pcs

anti-static service pad

reversible ratch handle

bit group

7 pcs hex key

1 5 2 0 2 5 3 0 4 0 5 0 .... Stair Tool With Handle Coating Mts-20013 - By maximumco - On Tuesday 15 March 2022 3:09 am: stair tool with handle coating mts-20013

flooring accessories

1 used for tucking carpet into the tackles strip wall gully and to drive carpet into a stair crotch

2 forged chrome plated....

Stair Tool With Handle Coating Mts-20013 - By maximumco - On Tuesday 15 March 2022 3:09 am: stair tool with handle coating mts-20013

flooring accessories

1 used for tucking carpet into the tackles strip wall gully and to drive carpet into a stair crotch

2 forged chrome plated.... Single Door Garden Tool Storage Shed 1 Room - By topplabill - On Thursday 22 December 2022 4:37 am: single door garden tool storage shed 1 room

mini size storage solution for tooling with size 8 2 * 7 4 * 3 8 feet

external dimensions

1 room l1160*w2260*h2500mm

internal dimensions

1 roo....

Single Door Garden Tool Storage Shed 1 Room - By topplabill - On Thursday 22 December 2022 4:37 am: single door garden tool storage shed 1 room

mini size storage solution for tooling with size 8 2 * 7 4 * 3 8 feet

external dimensions

1 room l1160*w2260*h2500mm

internal dimensions

1 roo.... Import Export Startup Stories

Import Export Startup Stories

Share Your Story & Get Listed at StartImportExport.com- Jie Mei Precision Mould Ltd: John Zhang Of Jie Mei Precision Mould From China

- Mahadev Wood Industries: Bharat Variya Of Mahadev Wood Industries, Manufacturing Branded Coded Ready To Use Premium Wood products From India

- Guiyang Joint Win Import And Export Co Ltd: Shirley Of Guiyang Joint Win Import And Export From China

- Packware Corporation: Charles Wu Of Packware Corporation Specializing In Packaging Products From Taiwan

Plastic inserted injection molding Classification Navigation

Plastic inserted injection molding Classification Navigation

Main - Manufacturing Components and Supplies - Moldings - Inserted injection moldings - Plastic inserted injection molding [3]

TradersCity.com shall not be held liable for any user posted/submitted content including but not limited to trade leads, profiles, images, and any other data. TradersCity.com does not and did not verify any of users posted/submitted data nor is implicitly or explicitly recommending these business offers. TradersCity does not verify truthfulness, accuracy, completeness, nor legality of any businesses, services, and leads posted here. TradersCity does not represent Sellers or Buyers in any transaction between users of the website and is unable to make any opinion in regard to their performance in any transaction. TradersCity neither guarantees nor undertakes in any dispute between sellers and buyers. Protect your business from fraud by trading safely