A free import export trade leads B2B marketplace since 1996 for manufacturers, suppliers, exporters, importers, buyers, sellers, wholesalers, freight forwarders, shippers, trade shows, exhibits, and export management.

Hello visitor from USA - 47 visiting from

USA - 47 visiting from  18 USA

18 USA  13 Canada

13 Canada  4 France

4 France  3 Germany

3 Germany  2 China

2 China  2 Hong Kong

2 Hong Kong  1 New Zealand

1 New Zealand  1 Singapore

1 Singapore  1 UK

1 UK  1 Zimbabwe

1 Zimbabwe  1 Ireland

1 Ireland

Hello visitor from

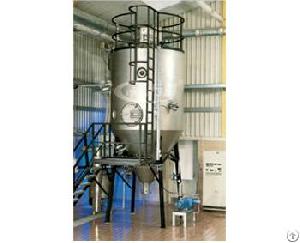

Lpg Series High-speed Centrifugal Spray Dryer

Posted at: Offers to Sell and Export | Posted on: Monday 7 October 2013 3:44 am | Poster last visit: Friday 18 July 2014 |

Product Description:

Description:

The spray drying is the technology widest used in the liquid technology shaping and in

the drying industry. This equipment is especially suitable for producing powder or particle solid products from materials such as solution, emulsion, suspension and pasty states. For this reason, the particle size and distribution of the final products, the residual water contents, the stacking density and the particle shape must meet the precision standard.

Features:

1. At a high speed of drying, the superficial of the feed liquid will be increased greatly after the spraying. In the hot-air flow, 95%-98% of wather can be evaporated at a moment. The time of completing the drying needs only several seconds.

2. This is especially suitable for drying the heat sensitive materials. Its final products are high in purity and good in quality. And they have good uniformity, mobility, dissolving capacity. The production procedures are simple, the operation and control are easy.

3. The liquid with the moisture contents 40%-60% (for special materials, the contents may reach 90%) can be dried into powder or particle products at one time. After the drying, there is no need for smashing and sorting, so it reduce the operation procedures in the production and enhance the product purity. The product particle diameters, looseness and water contents can be adjusted through changing the operation condition in a certain scope. It is very convenient to control and manage.

Principle:

After the filtering and heating, the air enters into the air distributor on the top of the dryer. The hot air enters into the drying room in the spiral form and uniformly. By passing through the high-speed centrifugal spray on the top of the tower, the liquid material will rotate and be sprayed into the extremely fine mist liquid beads. Through the very short time of contacting the hot air, the materials can be dried into the final products. The final products will be discharged continuously from the bottom of the drying tower and from the cyclone separator. The waste gas will be discharged from blower.

Applications:

1. Chemical: sodium fluoride(potassium), alkaline dyestuff and pigment, dyestuff intermediate, compound fertilizer, formic silicic acid, catalyst, sulphuric acid agent, amino acid, white carbon and so on.

2. Plastics and resin: AB, ABS emulsion, uric acid resin, phenolic aldehyde resin, urea-formaldehyde resin, formaldehyde resin, polythene, poly-chloroprene and so on.

3. Foodstuff: fatty milk powder, protein, cocoa milk powder, substitute milk powder, albumen (yolk), food and plant, oats, chicken juice, coffee, instant dissoluble tea, seasoning meat, protein, soybean, peanut protein, hydrolysate and so on.

4. Ceramic: aluminium oxide, ceramic tile material, magnesium oxide, talcum and so on.

Optional Information

- Payment : T/T

- Delivery : One to Two Month

- Origin : Jiangsu, China

- Minimum Order : 1

- Samples : Not Available

Company Contact:

Contact Name: Macy Gao

Company Name: Changzhou Wanji Drying & Granulating Equipment Co., Ltd

Email:

Tel: +86-519-88910006

Fax: +86-519-88902866

Street Address: Jiaoxi Town

Changzhou, Jiangsu 213116

China

Member name: WanjiEnterprise

Country: China

China

Member Since: 05 October 2013

Total Leads: 58 WanjiEnterprise Import Export Business Leads

Business focus: Dryer, Granulator, Mixer, Grinder

Chat:

Verify: Safe Import Export Tips

The spray drying is the technology widest used in the liquid technology shaping and in

the drying industry. This equipment is especially suitable for producing powder or particle solid products from materials such as solution, emulsion, suspension and pasty states. For this reason, the particle size and distribution of the final products, the residual water contents, the stacking density and the particle shape must meet the precision standard.

Features:

1. At a high speed of drying, the superficial of the feed liquid will be increased greatly after the spraying. In the hot-air flow, 95%-98% of wather can be evaporated at a moment. The time of completing the drying needs only several seconds.

2. This is especially suitable for drying the heat sensitive materials. Its final products are high in purity and good in quality. And they have good uniformity, mobility, dissolving capacity. The production procedures are simple, the operation and control are easy.

3. The liquid with the moisture contents 40%-60% (for special materials, the contents may reach 90%) can be dried into powder or particle products at one time. After the drying, there is no need for smashing and sorting, so it reduce the operation procedures in the production and enhance the product purity. The product particle diameters, looseness and water contents can be adjusted through changing the operation condition in a certain scope. It is very convenient to control and manage.

Principle:

After the filtering and heating, the air enters into the air distributor on the top of the dryer. The hot air enters into the drying room in the spiral form and uniformly. By passing through the high-speed centrifugal spray on the top of the tower, the liquid material will rotate and be sprayed into the extremely fine mist liquid beads. Through the very short time of contacting the hot air, the materials can be dried into the final products. The final products will be discharged continuously from the bottom of the drying tower and from the cyclone separator. The waste gas will be discharged from blower.

Applications:

1. Chemical: sodium fluoride(potassium), alkaline dyestuff and pigment, dyestuff intermediate, compound fertilizer, formic silicic acid, catalyst, sulphuric acid agent, amino acid, white carbon and so on.

2. Plastics and resin: AB, ABS emulsion, uric acid resin, phenolic aldehyde resin, urea-formaldehyde resin, formaldehyde resin, polythene, poly-chloroprene and so on.

3. Foodstuff: fatty milk powder, protein, cocoa milk powder, substitute milk powder, albumen (yolk), food and plant, oats, chicken juice, coffee, instant dissoluble tea, seasoning meat, protein, soybean, peanut protein, hydrolysate and so on.

4. Ceramic: aluminium oxide, ceramic tile material, magnesium oxide, talcum and so on.

Optional Information

- Payment : T/T

- Delivery : One to Two Month

- Origin : Jiangsu, China

- Minimum Order : 1

- Samples : Not Available

Company Contact:

Contact Name: Macy Gao

Company Name: Changzhou Wanji Drying & Granulating Equipment Co., Ltd

Email:

Tel: +86-519-88910006

Fax: +86-519-88902866

Street Address: Jiaoxi Town

Changzhou, Jiangsu 213116

China

Member name: WanjiEnterprise

Country:

Member Since: 05 October 2013

Total Leads: 58 WanjiEnterprise Import Export Business Leads

Business focus: Dryer, Granulator, Mixer, Grinder

Chat:

Verify: Safe Import Export Tips

Similar Suppliers And Manufacturers Import Export Trade Leads

Similar Suppliers And Manufacturers Import Export Trade Leads

Walk In Salt Spray Chamber Temperature Humidity Combine Salt Spray - By alibiota - On Thursday 25 April 2024 2:52 am: spray chamber is different from basic salt spray test chamber walk in salt spray chamber exposes sample to a series of different environments in repet....

Walk In Salt Spray Chamber Temperature Humidity Combine Salt Spray - By alibiota - On Thursday 25 April 2024 2:52 am: spray chamber is different from basic salt spray test chamber walk in salt spray chamber exposes sample to a series of different environments in repet.... Kge Construction Industry Powder Coating Spray Paint Polyester Resin Spray Powder Coating - By KGECHEMICAL - On Tuesday 28 May 2024 9:06 am: kge construction industry powder coating spray paint polyester resin spray powder coating

discription the series of products are made of saturated carboxylpolyester resin tgic or haa rutile titanium dioxide which are the main raw mater....

Kge Construction Industry Powder Coating Spray Paint Polyester Resin Spray Powder Coating - By KGECHEMICAL - On Tuesday 28 May 2024 9:06 am: kge construction industry powder coating spray paint polyester resin spray powder coating

discription the series of products are made of saturated carboxylpolyester resin tgic or haa rutile titanium dioxide which are the main raw mater.... Lpg Cylinder - By suppliercylinder - On Friday 12 May 2023 8:37 am: lpg is by far the most versatile portable cleanest most accessible and efficient energy source readily available to consumers around the world and....

Lpg Cylinder - By suppliercylinder - On Friday 12 May 2023 8:37 am: lpg is by far the most versatile portable cleanest most accessible and efficient energy source readily available to consumers around the world and.... Horizontal Centrifugal Pumps - By shoufei - On Tuesday 18 October 2022 6:05 am: centrifugal pumps

cm series are used in air conditioning systems cooling systems industrial cleaning water treatment purification of water aqua....

Horizontal Centrifugal Pumps - By shoufei - On Tuesday 18 October 2022 6:05 am: centrifugal pumps

cm series are used in air conditioning systems cooling systems industrial cleaning water treatment purification of water aqua.... Centrifugal Spinning Machine - By zongheng - On Saturday 13 May 2023 7:03 am: centrifugal spinning machine consists of base bearing seat coupling centrifugal shaft etc

amp #9679 centrifugal force acts to distribute the....

Centrifugal Spinning Machine - By zongheng - On Saturday 13 May 2023 7:03 am: centrifugal spinning machine consists of base bearing seat coupling centrifugal shaft etc

amp #9679 centrifugal force acts to distribute the.... Horizontal Multistage Centrifugal Pump - By shoufei - On Tuesday 18 October 2022 6:03 am: centrifugal pumps equipped with extended shaft motors the compact structure makes the pump small in size with axial inlet and radial outlet most pa....

Horizontal Multistage Centrifugal Pump - By shoufei - On Tuesday 18 October 2022 6:03 am: centrifugal pumps equipped with extended shaft motors the compact structure makes the pump small in size with axial inlet and radial outlet most pa.... Slurry Pump Centrifugal Ground - By kenshinepump - On Friday 31 March 2023 6:24 am: slurry pump centrifugal ground

zj slurry pump is a horizontal single stage single suction cantilever double shell structure widely used to transport slurry containing solid pa....

Slurry Pump Centrifugal Ground - By kenshinepump - On Friday 31 March 2023 6:24 am: slurry pump centrifugal ground

zj slurry pump is a horizontal single stage single suction cantilever double shell structure widely used to transport slurry containing solid pa.... Multipurpose Spray Adhesive - By DayangAerosol - On Saturday 22 July 2023 9:27 am: sprayidea 92 industrial multipurpose spray adhesive is suitable for bonding all kinds of light materials such as paper fabric foam plastic acrylic....

Multipurpose Spray Adhesive - By DayangAerosol - On Saturday 22 July 2023 9:27 am: sprayidea 92 industrial multipurpose spray adhesive is suitable for bonding all kinds of light materials such as paper fabric foam plastic acrylic.... Import Export Startup Stories

Import Export Startup Stories

Share Your Story & Get Listed at StartImportExport.com- Global CCTV Security Co Ltd: Julie Zhang Of Global CCTV Security, A Manufacturer Supplier Of Video Surveillance And Security camera Products

- Led Lamp Lighting Company: Tony Lee Of Led Lamp Lighting Company Specializing in Production And Sale Of Indoor And Outdoor LED Lights

- Xeno Company China: Lywin Of Xeno Specializing in Research, Design and Manufacturing High Power LED Flashlights From China

- Shaoxing Marina Biotechnology: James Han Of Shaoxing Marina Biotechnology From China

TradersCity.com shall not be held liable for any user posted/submitted content including but not limited to trade leads, profiles, images, and any other data. TradersCity.com does not and did not verify any of users posted/submitted data nor is implicitly or explicitly recommending these business offers. TradersCity does not verify truthfulness, accuracy, completeness, nor legality of any businesses, services, and leads posted here. TradersCity does not represent Sellers or Buyers in any transaction between users of the website and is unable to make any opinion in regard to their performance in any transaction. TradersCity neither guarantees nor undertakes in any dispute between sellers and buyers. Protect your business from fraud by trading safely