A free import export trade leads B2B marketplace since 1996 for manufacturers, suppliers, exporters, importers, buyers, sellers, wholesalers, freight forwarders, shippers, trade shows, exhibits, and export management.

Hello visitor from USA - 57 visiting from

USA - 57 visiting from  27 USA

27 USA  11 Canada

11 Canada  7 Germany

7 Germany  6 France

6 France  3 Belgium

3 Belgium  1 Hong Kong

1 Hong Kong  1 Iran

1 Iran  1 Ukraine

1 Ukraine

Hello visitor from

Mac-g320 Automatic Mold Flux Feeding Machine

Posted at: Offers to Sell and Export | Posted on: Thursday 8 September 2022 3:06 am | Poster last visit: Friday 7 June 2024 |

Product Category: Main

» Industrial Production and Manufacturing Services

» Machinery and transport equipment manufacture

» Manufacture of machinery

» Metallurgical machinery or equipment manufacture services

» Mac-g320 Automatic Mold Flux Feeding Machine

Product Description:

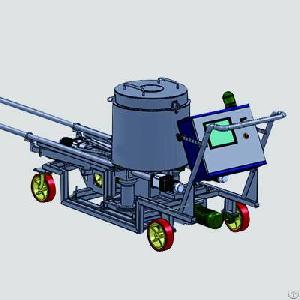

MAC-G320 Automatic Mold Flux Feeding Machine

Overview

MAC-G320 automatic mold flux feeding system is

a new generation product of automatic adding mold flux, which is independently developed by Wuhan CenterRise M&C Engineering Co., Ltd. According to different steel grades, casting speed, vibration and other process parameters, then the system can analyze and calculate the accurate mold flux addition amount through intelligent software. Then the system sends out signals to control the mold flux addition process and mold flux addition amount, and designs appropriate nozzles and propellers according to the fluidity of molten steel in the mold and the ductility of mold flux. After the system setting is completed, there is no manual intervention is required. It completely replaces the whole process of manual addition of mold flux, and realizes the automation of mold flux addition.

The features of the system

1. The system automatically controls the amount, process and time of adding mold flux according to the process requirements of automatic mold flux addition, so as to maintain the physical state of the mold flux and prevent it from being broken.

2. The user can match different parameters according to actual needs, so as to change the length of the mold flux feeding time and the amount of mold flux, which can suit for the use of different sections and different casting speeds.

3. The casting speed signal is used and the amount of adding mold flux can be automatically adjusted according to the casting speed. The mold flux can be added timely and evenly, which can improve the quality of the billet and reduce labor intensity.

4. The time is controlled by PLC, no manual intervention is required. The adjustment is very convenient. It has manual, automatic, local and remote control modes.

5. The system has reliable performance and simple structure, and can be adapted to powder and granular mold flux.

6. It has a special anti-blocking nozzle and backflushing design to overcome the phenomenon of pipeline blockage.

7. Strong operability, simple and convenient maintenance, and low maintenance cost.

8. It can maintain the even distribution of the flux layer in the mold.

The composition of the system

The system consists of feeding trolley, feeding bucket, swing arm and feeder motor, swing arm transmission device, PLC and control equipment.

1. The feeding trolley is the support and walking equipment of the mold flux feeder. The basic equipment of the adding mold flux machine is installed on the feeding trolley. At the same time, the trolley can easily make the mold flux feeder walk to the working position or the parking position.

2. The feeding bucket is a device for holding mold flux. The mold flux is pre-filled in the feeding bucket and is evenly output through the feeder. The feeding bucket is provided with alarm contact of mold flux level limit..

3. The swing arm and the feeder motor form a feeding and conveying device. The mold flux is evenly transmitted to the feed opening at the front end of the swing arm through the screw distributing device controlled by the motor. Then the mold flux can be used for mold distribution.

4. PLC and control equipment adjust and control the mold flux feeding speed, operation mode and control mode of the mold flux feeding machine, and realize various control modes and rates.

5. The swing arm transmission device controls the reciprocating motion of the swing arm according to the size of different molds, so that the mold flux is evenly distributed in the mold.

The technical parameter

Mold width: 500-2000mm

Mold thickness: 100-500mm

Type: screw conveying type mold flux feeding machine

Heating method: stirring electric heating

Arrangement location: on the pouring platform (with its own wheels to move)

Adding capacity: 0.5~7.5L/min, continuously adjustable feeding tube

Molding flux storage tank: ~125 L, with material level detection and alarm

Control mode: local/remote control, automatic /manual mode

Molding flux type: granular flux or powder flux

flux adding method: spiral swing adding flux

Casting speed interlock: yes

Mould size setting: yes

Signal transmission: DP/Industrial Ethernet

Company Contact:

Contact Name: Floria Liang

Company Name: Wuhan Centerrise M&c Engineering Co., Ltd.

Email:

Tel: 13995588597

Fax:

Street Address: Building 4, Hengxin

Industrial Park, No. 8 Xinhua

Avenue, Huangpi District

Wuhan, Hubei 432200

China

Member name: WuhanCenterRise

Country: China

China

Member Since: 06 September 2022

Total Leads: 25 WuhanCenterRise Import Export Business Leads

Business focus: Mold Breakout Prediction System, Ladle Slag Detection System, Mold Expert System, Continuous Casting Billet Detection System, Roll Gap Measuring Instr

Chat:

Verify: Safe Import Export Tips

Overview

MAC-G320 automatic mold flux feeding system is

a new generation product of automatic adding mold flux, which is independently developed by Wuhan CenterRise M&C Engineering Co., Ltd. According to different steel grades, casting speed, vibration and other process parameters, then the system can analyze and calculate the accurate mold flux addition amount through intelligent software. Then the system sends out signals to control the mold flux addition process and mold flux addition amount, and designs appropriate nozzles and propellers according to the fluidity of molten steel in the mold and the ductility of mold flux. After the system setting is completed, there is no manual intervention is required. It completely replaces the whole process of manual addition of mold flux, and realizes the automation of mold flux addition.

The features of the system

1. The system automatically controls the amount, process and time of adding mold flux according to the process requirements of automatic mold flux addition, so as to maintain the physical state of the mold flux and prevent it from being broken.

2. The user can match different parameters according to actual needs, so as to change the length of the mold flux feeding time and the amount of mold flux, which can suit for the use of different sections and different casting speeds.

3. The casting speed signal is used and the amount of adding mold flux can be automatically adjusted according to the casting speed. The mold flux can be added timely and evenly, which can improve the quality of the billet and reduce labor intensity.

4. The time is controlled by PLC, no manual intervention is required. The adjustment is very convenient. It has manual, automatic, local and remote control modes.

5. The system has reliable performance and simple structure, and can be adapted to powder and granular mold flux.

6. It has a special anti-blocking nozzle and backflushing design to overcome the phenomenon of pipeline blockage.

7. Strong operability, simple and convenient maintenance, and low maintenance cost.

8. It can maintain the even distribution of the flux layer in the mold.

The composition of the system

The system consists of feeding trolley, feeding bucket, swing arm and feeder motor, swing arm transmission device, PLC and control equipment.

1. The feeding trolley is the support and walking equipment of the mold flux feeder. The basic equipment of the adding mold flux machine is installed on the feeding trolley. At the same time, the trolley can easily make the mold flux feeder walk to the working position or the parking position.

2. The feeding bucket is a device for holding mold flux. The mold flux is pre-filled in the feeding bucket and is evenly output through the feeder. The feeding bucket is provided with alarm contact of mold flux level limit..

3. The swing arm and the feeder motor form a feeding and conveying device. The mold flux is evenly transmitted to the feed opening at the front end of the swing arm through the screw distributing device controlled by the motor. Then the mold flux can be used for mold distribution.

4. PLC and control equipment adjust and control the mold flux feeding speed, operation mode and control mode of the mold flux feeding machine, and realize various control modes and rates.

5. The swing arm transmission device controls the reciprocating motion of the swing arm according to the size of different molds, so that the mold flux is evenly distributed in the mold.

The technical parameter

Mold width: 500-2000mm

Mold thickness: 100-500mm

Type: screw conveying type mold flux feeding machine

Heating method: stirring electric heating

Arrangement location: on the pouring platform (with its own wheels to move)

Adding capacity: 0.5~7.5L/min, continuously adjustable feeding tube

Molding flux storage tank: ~125 L, with material level detection and alarm

Control mode: local/remote control, automatic /manual mode

Molding flux type: granular flux or powder flux

flux adding method: spiral swing adding flux

Casting speed interlock: yes

Mould size setting: yes

Signal transmission: DP/Industrial Ethernet

Company Contact:

Contact Name: Floria Liang

Company Name: Wuhan Centerrise M&c Engineering Co., Ltd.

Email:

Tel: 13995588597

Fax:

Street Address: Building 4, Hengxin

Industrial Park, No. 8 Xinhua

Avenue, Huangpi District

Wuhan, Hubei 432200

China

Member name: WuhanCenterRise

Country:

Member Since: 06 September 2022

Total Leads: 25 WuhanCenterRise Import Export Business Leads

Business focus: Mold Breakout Prediction System, Ladle Slag Detection System, Mold Expert System, Continuous Casting Billet Detection System, Roll Gap Measuring Instr

Chat:

Verify: Safe Import Export Tips

Similar Suppliers And Manufacturers Import Export Trade Leads

Similar Suppliers And Manufacturers Import Export Trade Leads

Nipple Feeding Machine Wheel Assembly Equipment - By juichihco - On Monday 4 March 2024 7:45 am: feeding our advanced solution redefines efficiency and accuracy in the bicycle and automotive manufacturing industries tailored specifically for the....

Nipple Feeding Machine Wheel Assembly Equipment - By juichihco - On Monday 4 March 2024 7:45 am: feeding our advanced solution redefines efficiency and accuracy in the bicycle and automotive manufacturing industries tailored specifically for the.... Pneumatic Flux Chipper Sm04a - By syairtool - On Thursday 30 March 2023 11:26 am: machine and

large instrument to clear off the rust and adhesion underside

specification

1 blow per minute 3000 b min

2 air inlet 1 4 quot

3 ....

Pneumatic Flux Chipper Sm04a - By syairtool - On Thursday 30 March 2023 11:26 am: machine and

large instrument to clear off the rust and adhesion underside

specification

1 blow per minute 3000 b min

2 air inlet 1 4 quot

3 .... Mac Aura Max Eye 19x40w Rgbw 4in1 Led Zoom Beam Wash Moving Head Light With Ring Effect - By yueyuanlights - On Friday 1 March 2024 1:57 am: mac aura max eye 19x40w rgbw 4in1 led zoom beam wash moving head light with ring effect model yy-sl8389 which is a wash moving head with a linear m....

Mac Aura Max Eye 19x40w Rgbw 4in1 Led Zoom Beam Wash Moving Head Light With Ring Effect - By yueyuanlights - On Friday 1 March 2024 1:57 am: mac aura max eye 19x40w rgbw 4in1 led zoom beam wash moving head light with ring effect model yy-sl8389 which is a wash moving head with a linear m.... Pump Feeding System For Precast Concrete Piles Manufacturing - By zongheng - On Saturday 13 May 2023 6:40 am: feeding system contains weighing amp amp measurement system walking system electronic control system and it consists of concrete pump weighting ....

Pump Feeding System For Precast Concrete Piles Manufacturing - By zongheng - On Saturday 13 May 2023 6:40 am: feeding system contains weighing amp amp measurement system walking system electronic control system and it consists of concrete pump weighting .... Injection Mold Engineering / Design - By eastoncorp - On Wednesday 30 March 2022 6:23 am: mold design engineering provider established in 1987 makes efforts in research and development of custom mold design

keep an open mind to explore ....

Injection Mold Engineering / Design - By eastoncorp - On Wednesday 30 March 2022 6:23 am: mold design engineering provider established in 1987 makes efforts in research and development of custom mold design

keep an open mind to explore .... Mold Surface Cladding Detection Equipment - By WuhanCenterRise - On Friday 17 February 2023 8:44 am: mold surface cladding detection equipment

overview amp #65306

this product is a new type of mold copper plate surface cladding detection equipment ....

Mold Surface Cladding Detection Equipment - By WuhanCenterRise - On Friday 17 February 2023 8:44 am: mold surface cladding detection equipment

overview amp #65306

this product is a new type of mold copper plate surface cladding detection equipment .... Laser Mold Taper Measuring Instrument - By WuhanCenterRise - On Friday 17 February 2023 8:45 am: mold multi-taper measuring instrument developed by our company the instrument adopts a high-precision high-sensitivity laser measurement and positio....

Laser Mold Taper Measuring Instrument - By WuhanCenterRise - On Friday 17 February 2023 8:45 am: mold multi-taper measuring instrument developed by our company the instrument adopts a high-precision high-sensitivity laser measurement and positio.... Fiberglass Hand Lay-up Mold Exterior Parts - By FiberglassComposites - On Monday 22 August 2022 2:23 am: mold design

6 reverse engineering

main advantages

1 light weight and strong

2 corrosion resistant

3 insulation for heat amp amp electric ....

Fiberglass Hand Lay-up Mold Exterior Parts - By FiberglassComposites - On Monday 22 August 2022 2:23 am: mold design

6 reverse engineering

main advantages

1 light weight and strong

2 corrosion resistant

3 insulation for heat amp amp electric .... Import Export Startup Stories

Import Export Startup Stories

Share Your Story & Get Listed at StartImportExport.com- K and R International: Vijay Rawal Of K And R International Offering Packaging And Filling Machines From India

- Sheng Chyean Enterprise Co Ltd: Ming Liu Of Sheng Chyean Enterprise Providing Maintenance Service To Local Wire Drawing Mills From Taiwan

- Shenzhen RiOu Refrigeration Machine Equipment Co Ltd: Vivian Hu Of Shenzhen RiOu Refrigeration Machine Equipment Company From China

- Sunware Corporation Limited: Evan Yang Of Sunware Corporation From China Supplying Antimicrobial Borosilicate Glass

- Al Rahma For Import And Export: Yasser Arfa Of Al Rahma For Import And Export From Egypt

Metallurgical machinery or equipment manufacture services Classification Navigation

Metallurgical machinery or equipment manufacture services Classification Navigation

Main - Industrial Production and Manufacturing Services - Machinery and transport equipment manufacture - Manufacture of machinery - Metallurgical machinery or equipment manufacture services [39]

TradersCity.com shall not be held liable for any user posted/submitted content including but not limited to trade leads, profiles, images, and any other data. TradersCity.com does not and did not verify any of users posted/submitted data nor is implicitly or explicitly recommending these business offers. TradersCity does not verify truthfulness, accuracy, completeness, nor legality of any businesses, services, and leads posted here. TradersCity does not represent Sellers or Buyers in any transaction between users of the website and is unable to make any opinion in regard to their performance in any transaction. TradersCity neither guarantees nor undertakes in any dispute between sellers and buyers. Protect your business from fraud by trading safely