A free import export trade leads B2B marketplace since 1996 for manufacturers, suppliers, exporters, importers, buyers, sellers, wholesalers, freight forwarders, shippers, trade shows, exhibits, and export management.

Hello visitor from USA - 43 visiting from

USA - 43 visiting from  27 USA

27 USA  10 Canada

10 Canada  2 UK

2 UK  1 Iran

1 Iran  1 Brazil

1 Brazil  1 China

1 China  1 Germany

1 Germany

Hello visitor from

Mlc-v235 Continuous Casting Mold Level Automatic Measurement System

Posted at: Offers to Sell and Export | Posted on: Friday 9 September 2022 1:52 am | Poster last visit: Friday 7 June 2024 |

Product Category: Main

» Industrial Production and Manufacturing Services

» Machinery and transport equipment manufacture

» Manufacture of machinery

» Metallurgical machinery or equipment manufacture services

» Mlc-v235 Continuous Casting Mold Level Automatic Measurement System

Product Description:

MLC-V235 Continuous Casting Mold Level Automatic Measurement System

Overview

The automatic control

for the molten steel level of the mold is one of the key technologies of continuous casting production. It is very important to reduce the labor intensity of workers, improve production efficiency, improve the quality and output of casting billet, reduce overflow and breakout of steel and improve the management level of steelmaking and continuous casting.

The molten steel is poured into the mold. In order to prevent overflow, the molten steel level must be kept stable. Otherwise, during the casting process, if the level will fluctuate too much, and slag will be involved, forming surface slag inclusion on the surface of the casting billet, affecting the quality of the billet. The test points out that the relationship between the level fluctuation and the depth of casting billet surface slag inclusion is as follows:

The experience has shown that surface slag inclusions can be eliminated when the level fluctuation is within ±10mm. At the same time, if the level fluctuation is more than 10mm, the rate of longitudinal cracks on the casting billet surface is 30%. It means that the level fluctuation directly affects the surface quality of the casting billet.

The principle of the system

The eddy current type molten steel level gauge is the key to the system. The system operates reliably and has excellent performance: high temperature resistance, strong anti-interference ability, fast dynamic response (lag time <0.10s), high detection accuracy (<±05mm), and large measurement range (0-150mm). The selected electromagnetic field frequency ensures that the level detection probe only detects the level change of the mold and does not detect the mold flux or steel slag layer. The system has the advantages of simple operation and no radiation protection problems. The system is insensitive to argon blowing, and its sensors can be mounted on the tundish car or on the platform.

The sensor is cooled by compressed air during use.

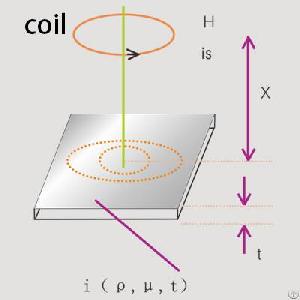

The principle is shown in the figure

A high-frequency exciting winding is installed above the molten steel surface of the mold. The magnetic field produced by exciting winding make induced eddy current appear. The magnetic field generated by the induced eddy current is in the opposite direction to the magnetic field generated by the high-frequency exciting winding, which changes the impedance of the high-frequency exciting winding. Under the condition that the winding material and structure, steel grade, temperature remain unchanged, the coil impedance change only has a single-value function relationship with the height of the molten steel level. As long as the impedance change of the high-frequency winding is detected, the change of the molten steel level in the mold can be converted.

The components of the system

Continuous casting mold level automatic control system is composed of eddy current tyoe molten steel level gauge, controller and digital actuator for adjusting the opening of tundish stopper.

The detection end of the mold level automatic control system is ① eddy current displacement sensor, which uses the eddy current mutual inductance effect between the energized coil and the metal conductor to detect the distance. The effective signal of the eddy current sensor is amplified and linearized by the circuit of ② mold level gauge, which converts the 0-150mm change in the molten steel level of the mold into a standard signal of 4-20mA.DC, and then transmits it to the ③ control computer to complete data processing and system control functions. We can also control the actuator manually and automatically through the ④on-site operation display control panel, and the opening of the stopper is controlled by the ⑤ actuator to realize the automatic control of the molten steel level.

1 Eddy current sensor;

2 mold level gauge;

3 control computer;

4 On-site operation display control panel;

5 digital actuator;

The control principle of the system

The system can be set to four control modes: automatic, semi-automatic, manual and motor clutch. The automatic mode is the closed-loop control system of the molten steel level, and control the opening of the stopper by the digital actuator; the semi-automatic mode uses opening degree setter and digital actuator to set the opening of the stopper manually; the manual mode is to open and close the button directly to control the opening of the stopper; the motor clutch mode is quickly changed from any of the above control methods to manual stopper operation.

The functions of the system also include: display and record of molten steel level, nozzle opening and casting speed; setting of molten steel level and nozzle opening; alarm of molten steel level at limit value etc.

In addition to taking the detection of molten steel level as the main feedback signal of the control system, the control system also considers various interference factors that have an impact on the level control. These interference factors include:

1. The influence of the change of the flow characteristics on the control system after the melt loss of the stopper

2. The influence of the weight change of molten steel in the tundish on the control system

3. The influence of the change of the casting speed of the continuous casting machine on the control system

4. The influence of the mold width change (the mold width is adjustable) on the control system

5. The influence of the vibration frequency and amplitude of the mold on the molten steel level gauge

The function and software implementation

In order to overcome these disturbances, the mold level control strategy adopts PID control. And on the basis of PID control, self-adaptive correction and feedforward control are introduced to form an advanced control system. The level control is the main loop, and there is a proportional gain of the main loop controller. According to the self-adaptive correction of the mold width change and feedforward compensation of casting speed, so as to further reduce and eliminate liquid level fluctuations caused by mold width adjustment and casting speed changes.

In order to reduce the frequent action of the stopper, the system adopts the intergarting time change of the controller, and automatically selects a longer intergarting time when the molten steel level fluctuates lightly. And the system will choose a shorter intergrating time when molten steel level fluctuates greatly. Thereby, the fluctuation of the controlled object caused by the frequent action of the stopper rod is suppressed.

In the signal processing of molten steel level gauge, an appropriate filtering link is added and the vibration frequency synchronous filter is used for filtering processing, which can overcome the interference of mold vibration frequency and amplitude variation.

The technical indexes

Company Contact:

Contact Name: Floria Liang

Company Name: Wuhan Centerrise M&c Engineering Co., Ltd.

Email:

Tel: 13995588597

Fax:

Street Address: Building 4, Hengxin

Industrial Park, No. 8 Xinhua

Avenue, Huangpi District

Wuhan, Hubei 432200

China

Member name: WuhanCenterRise

Country: China

China

Member Since: 06 September 2022

Total Leads: 25 WuhanCenterRise Import Export Business Leads

Business focus: Mold Breakout Prediction System, Ladle Slag Detection System, Mold Expert System, Continuous Casting Billet Detection System, Roll Gap Measuring Instr

Chat:

Verify: Safe Import Export Tips

Overview

The automatic control

for the molten steel level of the mold is one of the key technologies of continuous casting production. It is very important to reduce the labor intensity of workers, improve production efficiency, improve the quality and output of casting billet, reduce overflow and breakout of steel and improve the management level of steelmaking and continuous casting.

The molten steel is poured into the mold. In order to prevent overflow, the molten steel level must be kept stable. Otherwise, during the casting process, if the level will fluctuate too much, and slag will be involved, forming surface slag inclusion on the surface of the casting billet, affecting the quality of the billet. The test points out that the relationship between the level fluctuation and the depth of casting billet surface slag inclusion is as follows:

The experience has shown that surface slag inclusions can be eliminated when the level fluctuation is within ±10mm. At the same time, if the level fluctuation is more than 10mm, the rate of longitudinal cracks on the casting billet surface is 30%. It means that the level fluctuation directly affects the surface quality of the casting billet.

The principle of the system

The eddy current type molten steel level gauge is the key to the system. The system operates reliably and has excellent performance: high temperature resistance, strong anti-interference ability, fast dynamic response (lag time <0.10s), high detection accuracy (<±05mm), and large measurement range (0-150mm). The selected electromagnetic field frequency ensures that the level detection probe only detects the level change of the mold and does not detect the mold flux or steel slag layer. The system has the advantages of simple operation and no radiation protection problems. The system is insensitive to argon blowing, and its sensors can be mounted on the tundish car or on the platform.

The sensor is cooled by compressed air during use.

The principle is shown in the figure

A high-frequency exciting winding is installed above the molten steel surface of the mold. The magnetic field produced by exciting winding make induced eddy current appear. The magnetic field generated by the induced eddy current is in the opposite direction to the magnetic field generated by the high-frequency exciting winding, which changes the impedance of the high-frequency exciting winding. Under the condition that the winding material and structure, steel grade, temperature remain unchanged, the coil impedance change only has a single-value function relationship with the height of the molten steel level. As long as the impedance change of the high-frequency winding is detected, the change of the molten steel level in the mold can be converted.

The components of the system

Continuous casting mold level automatic control system is composed of eddy current tyoe molten steel level gauge, controller and digital actuator for adjusting the opening of tundish stopper.

The detection end of the mold level automatic control system is ① eddy current displacement sensor, which uses the eddy current mutual inductance effect between the energized coil and the metal conductor to detect the distance. The effective signal of the eddy current sensor is amplified and linearized by the circuit of ② mold level gauge, which converts the 0-150mm change in the molten steel level of the mold into a standard signal of 4-20mA.DC, and then transmits it to the ③ control computer to complete data processing and system control functions. We can also control the actuator manually and automatically through the ④on-site operation display control panel, and the opening of the stopper is controlled by the ⑤ actuator to realize the automatic control of the molten steel level.

1 Eddy current sensor;

2 mold level gauge;

3 control computer;

4 On-site operation display control panel;

5 digital actuator;

The control principle of the system

The system can be set to four control modes: automatic, semi-automatic, manual and motor clutch. The automatic mode is the closed-loop control system of the molten steel level, and control the opening of the stopper by the digital actuator; the semi-automatic mode uses opening degree setter and digital actuator to set the opening of the stopper manually; the manual mode is to open and close the button directly to control the opening of the stopper; the motor clutch mode is quickly changed from any of the above control methods to manual stopper operation.

The functions of the system also include: display and record of molten steel level, nozzle opening and casting speed; setting of molten steel level and nozzle opening; alarm of molten steel level at limit value etc.

In addition to taking the detection of molten steel level as the main feedback signal of the control system, the control system also considers various interference factors that have an impact on the level control. These interference factors include:

1. The influence of the change of the flow characteristics on the control system after the melt loss of the stopper

2. The influence of the weight change of molten steel in the tundish on the control system

3. The influence of the change of the casting speed of the continuous casting machine on the control system

4. The influence of the mold width change (the mold width is adjustable) on the control system

5. The influence of the vibration frequency and amplitude of the mold on the molten steel level gauge

The function and software implementation

In order to overcome these disturbances, the mold level control strategy adopts PID control. And on the basis of PID control, self-adaptive correction and feedforward control are introduced to form an advanced control system. The level control is the main loop, and there is a proportional gain of the main loop controller. According to the self-adaptive correction of the mold width change and feedforward compensation of casting speed, so as to further reduce and eliminate liquid level fluctuations caused by mold width adjustment and casting speed changes.

In order to reduce the frequent action of the stopper, the system adopts the intergarting time change of the controller, and automatically selects a longer intergarting time when the molten steel level fluctuates lightly. And the system will choose a shorter intergrating time when molten steel level fluctuates greatly. Thereby, the fluctuation of the controlled object caused by the frequent action of the stopper rod is suppressed.

In the signal processing of molten steel level gauge, an appropriate filtering link is added and the vibration frequency synchronous filter is used for filtering processing, which can overcome the interference of mold vibration frequency and amplitude variation.

The technical indexes

Company Contact:

Contact Name: Floria Liang

Company Name: Wuhan Centerrise M&c Engineering Co., Ltd.

Email:

Tel: 13995588597

Fax:

Street Address: Building 4, Hengxin

Industrial Park, No. 8 Xinhua

Avenue, Huangpi District

Wuhan, Hubei 432200

China

Member name: WuhanCenterRise

Country:

Member Since: 06 September 2022

Total Leads: 25 WuhanCenterRise Import Export Business Leads

Business focus: Mold Breakout Prediction System, Ladle Slag Detection System, Mold Expert System, Continuous Casting Billet Detection System, Roll Gap Measuring Instr

Chat:

Verify: Safe Import Export Tips

Similar Suppliers And Manufacturers Import Export Trade Leads

Similar Suppliers And Manufacturers Import Export Trade Leads

Bps-k600 Continuous Casting Mold Breakout System - By WuhanCenterRise - On Tuesday 6 September 2022 3:42 am: casting mold breakout system

overview

the continuous casting mould breakout prediction system is developed by wuhan centerrise m amp amp c measurin....

Bps-k600 Continuous Casting Mold Breakout System - By WuhanCenterRise - On Tuesday 6 September 2022 3:42 am: casting mold breakout system

overview

the continuous casting mould breakout prediction system is developed by wuhan centerrise m amp amp c measurin.... Zsq-t100 Online Surface Quality Inspection System For Casting Billet Eddy Current - By WuhanCenterRise - On Thursday 8 September 2022 3:05 am: casting billet eddy current

the principle of the system

the zsq-t100 online surface quality inspection system for casting billet adopts the princi....

Zsq-t100 Online Surface Quality Inspection System For Casting Billet Eddy Current - By WuhanCenterRise - On Thursday 8 September 2022 3:05 am: casting billet eddy current

the principle of the system

the zsq-t100 online surface quality inspection system for casting billet adopts the princi.... On-line Billet End Continuous Temperature Measurement - By WuhanCenterRise - On Friday 17 February 2023 8:37 am: casting machine the billets and their surrounding environmental factors such as scale steam shielding and other factors are considered in the sche....

On-line Billet End Continuous Temperature Measurement - By WuhanCenterRise - On Friday 17 February 2023 8:37 am: casting machine the billets and their surrounding environmental factors such as scale steam shielding and other factors are considered in the sche.... Mould Online Width Adjustment And Taper Measurement - By WuhanCenterRise - On Thursday 8 September 2022 2:50 am: casting machine the mold online width adjustment system is the key technology for efficient continuous casting the online mold width adjustment syst....

Mould Online Width Adjustment And Taper Measurement - By WuhanCenterRise - On Thursday 8 September 2022 2:50 am: casting machine the mold online width adjustment system is the key technology for efficient continuous casting the online mold width adjustment syst.... Video Measuring Machine Dimension Measurement Instruments X30y20 - By chutongelec - On Thursday 19 May 2022 6:04 am: measurement instruments x30y20 manual video image measuring machine

dimension measurement instruments move distance x30y20 axis the instrument machi....

Video Measuring Machine Dimension Measurement Instruments X30y20 - By chutongelec - On Thursday 19 May 2022 6:04 am: measurement instruments x30y20 manual video image measuring machine

dimension measurement instruments move distance x30y20 axis the instrument machi.... Tubular Level Vials - By hengshuiaohongg - On Friday 15 December 2023 4:30 am: level vials also known as bubble or spirit levels are used in construction and photography to ensure surface alignment

tubular level vials also kn....

Tubular Level Vials - By hengshuiaohongg - On Friday 15 December 2023 4:30 am: level vials also known as bubble or spirit levels are used in construction and photography to ensure surface alignment

tubular level vials also kn.... Round Level Vials - By hengshuiaohongg - On Friday 15 December 2023 4:23 am: level vials at a low price by aohong co

round level vials also known as circular level vials are spirit levels utilized to determine the levelness....

Round Level Vials - By hengshuiaohongg - On Friday 15 December 2023 4:23 am: level vials at a low price by aohong co

round level vials also known as circular level vials are spirit levels utilized to determine the levelness.... Acrylic Bubble Level Vials - By hengshuiaohongg - On Thursday 14 December 2023 3:41 am: level vials often use the terms “acrylic bubble level vial” and “pmma spirit level vial”

acrylic bubble spirit level vial is a sealed tube made of ac....

Acrylic Bubble Level Vials - By hengshuiaohongg - On Thursday 14 December 2023 3:41 am: level vials often use the terms “acrylic bubble level vial” and “pmma spirit level vial”

acrylic bubble spirit level vial is a sealed tube made of ac.... Import Export Startup Stories

Import Export Startup Stories

Share Your Story & Get Listed at StartImportExport.com- Shandong Strong Casting Co Ltd: Emily Zhao Of Shandong Strong Casting Company An OEM Manufacturer Of Iron, Steel, Aluminium, And Non-Ferrous Casting Parts

- K and R International: Vijay Rawal Of K And R International Offering Packaging And Filling Machines From India

- Ramo Selectronicx: Rahram Palaniyappan Of Ramo Selectronicx In the Business Of Security Electronic Products From India

- Shenzhen RiOu Refrigeration Machine Equipment Co Ltd: Vivian Hu Of Shenzhen RiOu Refrigeration Machine Equipment Company From China

- Umur Basim Ve Kirt. San. Ve Tic. A. S.: Canan Istemi Of Umur Basim Ve Kirt San Ve Tic From Turkey In The Production Of Continuous Form Printing

Metallurgical machinery or equipment manufacture services Classification Navigation

Metallurgical machinery or equipment manufacture services Classification Navigation

Main - Industrial Production and Manufacturing Services - Machinery and transport equipment manufacture - Manufacture of machinery - Metallurgical machinery or equipment manufacture services [39]

TradersCity.com shall not be held liable for any user posted/submitted content including but not limited to trade leads, profiles, images, and any other data. TradersCity.com does not and did not verify any of users posted/submitted data nor is implicitly or explicitly recommending these business offers. TradersCity does not verify truthfulness, accuracy, completeness, nor legality of any businesses, services, and leads posted here. TradersCity does not represent Sellers or Buyers in any transaction between users of the website and is unable to make any opinion in regard to their performance in any transaction. TradersCity neither guarantees nor undertakes in any dispute between sellers and buyers. Protect your business from fraud by trading safely