A free import export trade leads B2B marketplace since 1996 for manufacturers, suppliers, exporters, importers, buyers, sellers, wholesalers, freight forwarders, shippers, trade shows, exhibits, and export management.

Hello visitor from USA - 218 visiting from

USA - 218 visiting from  195 USA

195 USA  8 Singapore

8 Singapore  5 Hong Kong

5 Hong Kong  4 Brazil

4 Brazil  3 UK

3 UK  1 Turkey

1 Turkey  1 Bangladesh

1 Bangladesh  1 Germany

1 Germany

Hello visitor from

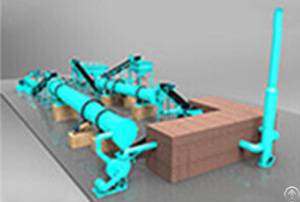

Organic Fertilizer Production Line Equipment

Posted at: Offers to Sell and Export | Posted on: Friday 4 September 2020 9:11 am | Poster last visit: Thursday 28 October 2021 | Targeted Countries: Nigeria | Rwanda | UAE

Product Category: Main

» Industrial Production and Manufacturing Services

» Plastic and chemical industries

» Chemicals and fertilizers production

» Fertilizers production services

» Organic Fertilizer Production Line Equipment

Product Description:

With the rapid development of the livestock and poultry industry, a large amount of manure and sewage

are generated. The harmful elements in these manures are seriously exceeded. It is difficult to treat them in the traditional returning method. In response to this situation, people have developed an organic fertilizer production line that integrates high-efficiency mixers, turning machines, granulators, and other fertilizer production equipment with mobile and high-efficiency solid-liquid separation technology as the core.

Use And Characteristics Of The Organic Fertilizer Production Line

The organic fertilizer production line is chicken manure, pig manure as raw materials, and does not contain any chemical ingredients. Chickens and pigs have poor digestion ability and can only consume 25% of the nutrients, while the other 75% of the nutrients in the feed discharged with the feces. The dried product contains nitrogen, phosphorus, potassium, organic matter, amino acids, proteins, and so on. Organic fertilizer granulation machinery has not only created economic benefits for enterprises but also made great contributions to human environmental protection projects.

Organic Fertilizer Production Line Includes Equipment

The organic fertilizer production line includes the following equipment:

Fertilizer crusher, belt conveyor machine, mixer, fertilizer granulator machine, dryer, cooler, sieving machine, finished product warehouse, packaging machine.

The production line consists of seven processes: batching, crushing, granulating, drying, sifting, cooling, and packaging.

Process Features

1. The particles are cylindrical.

2. The high content of organic matter, achieve pure organic granulation.

3. The use of organic particles under the force can inlay with each other's characteristics, no need to add adhesive when granulation.

4. The particles are strong, can sieve after granulation, reducing drying energy consumption.

5. The organic matter after fermentation does not need to dry, and the moisture content of the raw material can be 20-40%.

Market Prospect

1. Abundant resources

Biological waste is the same as oil, coal, and ore. It is the wealth and resources of society. The organic fertilizer production plant is rich in raw material resources.

2. High-quality fertilizer

These organic fertilizers are rich in various nutrients such as nitrogen, phosphorus, and potassium, with a content of more than 6% and an organic matter content of more than 35%, which are higher than the national standard.

3. High output

An organic fertilizer production line has an annual production capacity of 30, 000 tons and an annual treatment capacity of 80, 000 square meters.

4. Great market demand

An organic fertilizer production line can not only meet the local fertilizer needs but also provide to meet the needs of the surrounding market. Biological organic fertilizer widely used in fields such as farmland, fruit trees, flowers, landscaping, high-grade lawn, soil improvement, and so on.

Company Contact:

Contact Name: Amy Yan

Company Name: Zhengzhou Fusmar Machinery Co., Ltd

Email:

Tel: +8615838279423

Fax: +8615838279423

Street Address: No.45 Agricultural

Road, Jinshui District Zhengzhou,

Henan 450003 China

Other Contact Info:

Skype:

Website: https://www.feedpelletmills.com

Member name: FusmarMachinery

Country: China

China

Member Since: 28 May 2019

Total Leads: 216 FusmarMachinery Import Export Business Leads

Business focus: Pellet Mill, Fish Feed Machine, Charcoal Briquette Machine

Chat:

Verify: Safe Import Export Tips

are generated. The harmful elements in these manures are seriously exceeded. It is difficult to treat them in the traditional returning method. In response to this situation, people have developed an organic fertilizer production line that integrates high-efficiency mixers, turning machines, granulators, and other fertilizer production equipment with mobile and high-efficiency solid-liquid separation technology as the core.

Use And Characteristics Of The Organic Fertilizer Production Line

The organic fertilizer production line is chicken manure, pig manure as raw materials, and does not contain any chemical ingredients. Chickens and pigs have poor digestion ability and can only consume 25% of the nutrients, while the other 75% of the nutrients in the feed discharged with the feces. The dried product contains nitrogen, phosphorus, potassium, organic matter, amino acids, proteins, and so on. Organic fertilizer granulation machinery has not only created economic benefits for enterprises but also made great contributions to human environmental protection projects.

Organic Fertilizer Production Line Includes Equipment

The organic fertilizer production line includes the following equipment:

Fertilizer crusher, belt conveyor machine, mixer, fertilizer granulator machine, dryer, cooler, sieving machine, finished product warehouse, packaging machine.

The production line consists of seven processes: batching, crushing, granulating, drying, sifting, cooling, and packaging.

Process Features

1. The particles are cylindrical.

2. The high content of organic matter, achieve pure organic granulation.

3. The use of organic particles under the force can inlay with each other's characteristics, no need to add adhesive when granulation.

4. The particles are strong, can sieve after granulation, reducing drying energy consumption.

5. The organic matter after fermentation does not need to dry, and the moisture content of the raw material can be 20-40%.

Market Prospect

1. Abundant resources

Biological waste is the same as oil, coal, and ore. It is the wealth and resources of society. The organic fertilizer production plant is rich in raw material resources.

2. High-quality fertilizer

These organic fertilizers are rich in various nutrients such as nitrogen, phosphorus, and potassium, with a content of more than 6% and an organic matter content of more than 35%, which are higher than the national standard.

3. High output

An organic fertilizer production line has an annual production capacity of 30, 000 tons and an annual treatment capacity of 80, 000 square meters.

4. Great market demand

An organic fertilizer production line can not only meet the local fertilizer needs but also provide to meet the needs of the surrounding market. Biological organic fertilizer widely used in fields such as farmland, fruit trees, flowers, landscaping, high-grade lawn, soil improvement, and so on.

Company Contact:

Contact Name: Amy Yan

Company Name: Zhengzhou Fusmar Machinery Co., Ltd

Email:

Tel: +8615838279423

Fax: +8615838279423

Street Address: No.45 Agricultural

Road, Jinshui District Zhengzhou,

Henan 450003 China

Other Contact Info:

Skype:

Website: https://www.feedpelletmills.com

Member name: FusmarMachinery

Country:

Member Since: 28 May 2019

Total Leads: 216 FusmarMachinery Import Export Business Leads

Business focus: Pellet Mill, Fish Feed Machine, Charcoal Briquette Machine

Chat:

Verify: Safe Import Export Tips

Similar Suppliers And Manufacturers Import Export Trade Leads

Similar Suppliers And Manufacturers Import Export Trade Leads

Organic Matter Fertilizer - By diamondnano - On Thursday 14 July 2022 8:31 am: organic matter fertilizer manufacturer all liquid nutrients for plants are produced under strict quality control

product manufacturing technology i....

Organic Matter Fertilizer - By diamondnano - On Thursday 14 July 2022 8:31 am: organic matter fertilizer manufacturer all liquid nutrients for plants are produced under strict quality control

product manufacturing technology i.... New Type Organic Fertilizer Granulator - By tiancimachine - On Tuesday 6 September 2022 6:08 am: organic matter after fermentation crushing through the conventional organic prilling before granulating need not to dry and crush the raw materials ....

New Type Organic Fertilizer Granulator - By tiancimachine - On Tuesday 6 September 2022 6:08 am: organic matter after fermentation crushing through the conventional organic prilling before granulating need not to dry and crush the raw materials .... New Type Two In One Organic Fertilizer Granulator - By fertilizerproductionline - On Saturday 17 September 2022 9:15 am: organic substances after fermentation breaking through the convenientional organic granulation process the new technology of wet continuous putter g....

New Type Two In One Organic Fertilizer Granulator - By fertilizerproductionline - On Saturday 17 September 2022 9:15 am: organic substances after fermentation breaking through the convenientional organic granulation process the new technology of wet continuous putter g.... New Type Organic Fertilizer Granulator - By zhengzhouhuaqiang - On Tuesday 6 September 2022 7:43 am: organic fertilizer granulator manufacturer in china this series of new type organic fertilizer granulator is a new patented product developed by our c....

New Type Organic Fertilizer Granulator - By zhengzhouhuaqiang - On Tuesday 6 September 2022 7:43 am: organic fertilizer granulator manufacturer in china this series of new type organic fertilizer granulator is a new patented product developed by our c.... New Type Organic Fertilizer Granulator - By tianci - On Tuesday 6 September 2022 6:57 am: organic fertilizer granulator series is a new patented product researched and developed by our company and the agricultural machinery research institu....

New Type Organic Fertilizer Granulator - By tianci - On Tuesday 6 September 2022 6:57 am: organic fertilizer granulator series is a new patented product researched and developed by our company and the agricultural machinery research institu.... New Type Two In One Organic Fertilizer Granulator - By tianci - On Thursday 8 September 2022 7:12 am: organic matter especially for the coarse fiber materials which are difficult to be granulated by conventional equipment such as crop straw wine res....

New Type Two In One Organic Fertilizer Granulator - By tianci - On Thursday 8 September 2022 7:12 am: organic matter especially for the coarse fiber materials which are difficult to be granulated by conventional equipment such as crop straw wine res.... New Type Organic Fertilizer Granulator - By fertilizerproductionline - On Tuesday 6 September 2022 9:10 am: organic fertilizer granulator is widely used in organic fertilizer granulation due to more granulation rate stable operation strong and durable equ....

New Type Organic Fertilizer Granulator - By fertilizerproductionline - On Tuesday 6 September 2022 9:10 am: organic fertilizer granulator is widely used in organic fertilizer granulation due to more granulation rate stable operation strong and durable equ.... New Type Two In One Organic Fertilizer Granulator - By tiancimachine - On Thursday 8 September 2022 3:39 am: organic fertilizer granulator is used for granulation of various organic compounds after fermentation raw materials after crushing direct can be proc....

New Type Two In One Organic Fertilizer Granulator - By tiancimachine - On Thursday 8 September 2022 3:39 am: organic fertilizer granulator is used for granulation of various organic compounds after fermentation raw materials after crushing direct can be proc.... Import Export Startup Stories

Import Export Startup Stories

Share Your Story & Get Listed at StartImportExport.com- Shanghai MTC Industrial Co Ltd: Tony Tang Of Shanghai MTC Industrial Designing And Manufacturing Cold Roll Forming Machines From China

- Shanghai Allstar Industrial Co., Ltd: Tony Tang Of Shanghai Allstar Industrial, A Manufacturer Of Various Cold Roll Forming Machines From China

- KR Exports and Imports : Raguram Of KR Exports and Imports From India

- East International Toys Co Ltd: Bao shujian Of East International Toys Company, A Toys Manufacturer From China

- Zhejiang Kepu Water Industry Co Ltd: Jacky Of Zhejiang Kepu Water Industry, A Piping Systems And Irrigation Equipments Supplier From China

Fertilizers production services Classification Navigation

Fertilizers production services Classification Navigation

Main - Industrial Production and Manufacturing Services - Plastic and chemical industries - Chemicals and fertilizers production - Fertilizers production services [93]

TradersCity.com shall not be held liable for any user posted/submitted content including but not limited to trade leads, profiles, images, and any other data. TradersCity.com does not and did not verify any of users posted/submitted data nor is implicitly or explicitly recommending these business offers. TradersCity does not verify truthfulness, accuracy, completeness, nor legality of any businesses, services, and leads posted here. TradersCity does not represent Sellers or Buyers in any transaction between users of the website and is unable to make any opinion in regard to their performance in any transaction. TradersCity neither guarantees nor undertakes in any dispute between sellers and buyers. Protect your business from fraud by trading safely