A free import export trade leads B2B marketplace since 1996 for manufacturers, suppliers, exporters, importers, buyers, sellers, wholesalers, freight forwarders, shippers, trade shows, exhibits, and export management.

Hello visitor from USA - 70 visiting from

USA - 70 visiting from  24 USA

24 USA  12 Germany

12 Germany  11 Canada

11 Canada  8 France

8 France  7 Belgium

7 Belgium  3 Czech Republic

3 Czech Republic  3 UK

3 UK  1 Iran

1 Iran  1 Ukraine

1 Ukraine

Hello visitor from

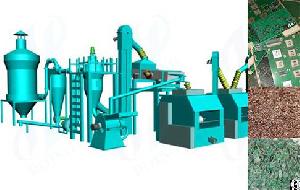

Pcb Recycling Machine / Circuit Board Recycling Machine

Posted at: Offers to Sell and Export | Posted on: Saturday 21 November 2015 6:40 am | Poster last visit: Friday 19 February 2016 |

Product Category: Main

» Industrial Cleaning Services

» Refuse disposal and treatment

» Recycling services

» Recycling of metal

» Pcb Recycling Machine / Circuit Board Recycling Machine

Product Description:

1.Brief inroduction of PCB recycling machine/circuit board recycling machine

PCB recycling machine/circuit

board recycling machine is mainly used to dismantle the electronic component from PCB of computer, TV set, and other electrical application facility. The PCB is heated by 7 electric resistance heaters to 250℃ to melt solder. The inner drum will spin out the solder and electronic component through 20mm*20mm screen from PCB board inside the drum. Then, the solder will be separated from the electronic component through vibrating screen 4mm*4mm. Solder recovery rate is 80%, and the purity is 60% as there is small pieces electronic component inside the solder. The recycled solder will be refined in an electrical resistance furnace to get the purity of 95%.

2.Working Principle of PCB recycling machine/circuit board recycling machine

PCB recycling machine/circuit board recycling machine adopts a process route that makes raw materials such as printed circuit boards to be a mixture of metal and resin fiber powder by dry crushing and pulverization and then separates the metals from the non-metal materials such as resin by high voltage electrostatic separator.

To avoid the pollution problem, it also equipped with impulse dust collector, it can work continually, which can effectively solve the pollution problem, all the indexes is up to national standard .

3.Features of PCB recycling machine/circuit board recycling machine:

1). New process of advanced mechanical pulverization and high voltage electrostatic separation is adopted so that the purity of metal and non-metal separated after crushing and dissociation is high;

2). The key technology is to organically integrate different breaking and dissociation equipment dedicated to various waste and used printed circuit board so as to achieve the maximum energy-saving effect and high metal separation rate;

3). The unit consumption of energy to treat one ton of waste and used printed circuit board is only about 3/5 of that of domestic product alike; the largest treatment capacity of one set of equipment is 1 ton per hour.

4). The price of it is only 1/5of the similar equipment at home and aboard, and the recovery rate of copper is about 3%-5% higher than other manufacturers of the sort.

5). It has good comprehensive performance, having special effect on computer board, calculator board, TV board and other control printed circuit board, and compatibility for recovery of various circuit boards with capacitor components.

Advantages of PCB recycling machine/circuit board recycling machine

1.Compact structure, reasonable layout, stable performance and low noise.

2. Uniform feed full production line adopts PLC control, coordinated operation.

3 three-stage crushing, handling capacity per hour 700-800kg.

4.Crushing chamber with circulating water temperature control and noise reduction.

5. full production line using negative pressure feeding effectively reduce dust overflow.

6.Back feeding system so crushed more efficient.

7. Airflow separation equipment sorting rate of 97 to 99%.

Company Contact:

Contact Name: Ms Bonnie

Company Name: Doingmechanical

Email:

Tel: +86 158 9380 0169

Fax:

Street Address: No.138 Yingxie Road,

Jinshui District, Zhengzhou, Henan

Province, China

Zhengzhou, Henan 450000

China

Website: https://www.copperwirerecyclingmachinery.com

Member name: DoingMechnical

Country: China

China

Member Since: 21 November 2015

Total Leads: 6 DoingMechnical Import Export Business Leads

Business focus: Copper Wire Recycling Machine, Pcb Circuit Board Recycling Machine, Aluminum Plastic Separation Machine

Chat:

Verify: Safe Import Export Tips

PCB recycling machine/circuit

board recycling machine is mainly used to dismantle the electronic component from PCB of computer, TV set, and other electrical application facility. The PCB is heated by 7 electric resistance heaters to 250℃ to melt solder. The inner drum will spin out the solder and electronic component through 20mm*20mm screen from PCB board inside the drum. Then, the solder will be separated from the electronic component through vibrating screen 4mm*4mm. Solder recovery rate is 80%, and the purity is 60% as there is small pieces electronic component inside the solder. The recycled solder will be refined in an electrical resistance furnace to get the purity of 95%.

2.Working Principle of PCB recycling machine/circuit board recycling machine

PCB recycling machine/circuit board recycling machine adopts a process route that makes raw materials such as printed circuit boards to be a mixture of metal and resin fiber powder by dry crushing and pulverization and then separates the metals from the non-metal materials such as resin by high voltage electrostatic separator.

To avoid the pollution problem, it also equipped with impulse dust collector, it can work continually, which can effectively solve the pollution problem, all the indexes is up to national standard .

3.Features of PCB recycling machine/circuit board recycling machine:

1). New process of advanced mechanical pulverization and high voltage electrostatic separation is adopted so that the purity of metal and non-metal separated after crushing and dissociation is high;

2). The key technology is to organically integrate different breaking and dissociation equipment dedicated to various waste and used printed circuit board so as to achieve the maximum energy-saving effect and high metal separation rate;

3). The unit consumption of energy to treat one ton of waste and used printed circuit board is only about 3/5 of that of domestic product alike; the largest treatment capacity of one set of equipment is 1 ton per hour.

4). The price of it is only 1/5of the similar equipment at home and aboard, and the recovery rate of copper is about 3%-5% higher than other manufacturers of the sort.

5). It has good comprehensive performance, having special effect on computer board, calculator board, TV board and other control printed circuit board, and compatibility for recovery of various circuit boards with capacitor components.

Advantages of PCB recycling machine/circuit board recycling machine

1.Compact structure, reasonable layout, stable performance and low noise.

2. Uniform feed full production line adopts PLC control, coordinated operation.

3 three-stage crushing, handling capacity per hour 700-800kg.

4.Crushing chamber with circulating water temperature control and noise reduction.

5. full production line using negative pressure feeding effectively reduce dust overflow.

6.Back feeding system so crushed more efficient.

7. Airflow separation equipment sorting rate of 97 to 99%.

Company Contact:

Contact Name: Ms Bonnie

Company Name: Doingmechanical

Email:

Tel: +86 158 9380 0169

Fax:

Street Address: No.138 Yingxie Road,

Jinshui District, Zhengzhou, Henan

Province, China

Zhengzhou, Henan 450000

China

Website: https://www.copperwirerecyclingmachinery.com

Member name: DoingMechnical

Country:

Member Since: 21 November 2015

Total Leads: 6 DoingMechnical Import Export Business Leads

Business focus: Copper Wire Recycling Machine, Pcb Circuit Board Recycling Machine, Aluminum Plastic Separation Machine

Chat:

Verify: Safe Import Export Tips

Similar Suppliers And Manufacturers Import Export Trade Leads

Similar Suppliers And Manufacturers Import Export Trade Leads

Radiator Recycling Machine - By optimarecycling - On Thursday 30 June 2022 1:31 am: recycling plant radiator recycling line manufacturer

optima radiator recycling plant can shred crush and separate scrap radiators to get se....

Radiator Recycling Machine - By optimarecycling - On Thursday 30 June 2022 1:31 am: recycling plant radiator recycling line manufacturer

optima radiator recycling plant can shred crush and separate scrap radiators to get se.... Waste Tire Recycling Machine - By optimarecycling - On Thursday 30 June 2022 1:30 am: recycling machine for sale

machine description

rubber crumb plant produce a fine wire free rubber granules that can be used for remanufactured rubbe....

Waste Tire Recycling Machine - By optimarecycling - On Thursday 30 June 2022 1:30 am: recycling machine for sale

machine description

rubber crumb plant produce a fine wire free rubber granules that can be used for remanufactured rubbe.... Scrap Radiator Recycling Machine - By optimarecycling - On Thursday 30 June 2022 1:30 am: pcb recycling copper and aluminum separator

Scrap Radiator Recycling Machine - By optimarecycling - On Thursday 30 June 2022 1:30 am: pcb recycling copper and aluminum separator  Dewatering Elements For Paper And Board Machine - By ShijiazhuangHuatao - On Saturday 11 June 2022 7:27 am: board is that it can be installed near the breast roller or the breast roller scraper can be installed it can move forwards and backwards and can b....

Dewatering Elements For Paper And Board Machine - By ShijiazhuangHuatao - On Saturday 11 June 2022 7:27 am: board is that it can be installed near the breast roller or the breast roller scraper can be installed it can move forwards and backwards and can b.... Recycling E Scraps - By POWERSTEP - On Tuesday 14 February 2023 8:28 am: recycling group powerstep hk always active in the recycling of

transformer scrap

electric motor scrap

shredder motor scrap

electric meter scrap

e....

Recycling E Scraps - By POWERSTEP - On Tuesday 14 February 2023 8:28 am: recycling group powerstep hk always active in the recycling of

transformer scrap

electric motor scrap

shredder motor scrap

electric meter scrap

e.... Sustainable Waste Management A And Recycling Services - By thekabadiwala - On Wednesday 26 April 2023 11:28 am: recycling industry to help support the system to create circular economy in india

through our tech enabled platform we are able to optimally utilize....

Sustainable Waste Management A And Recycling Services - By thekabadiwala - On Wednesday 26 April 2023 11:28 am: recycling industry to help support the system to create circular economy in india

through our tech enabled platform we are able to optimally utilize.... Circuit Breaker For Industrial Wiring - By arliselectric - On Wednesday 6 September 2023 8:10 am: circuit breaker for industrial wiring

circuit breaker for industrial wiring

type 100af 100 series

with a frame capacity of 100af the 100 series offers two main types the 100eb and ....

Circuit Breaker For Industrial Wiring - By arliselectric - On Wednesday 6 September 2023 8:10 am: circuit breaker for industrial wiring

circuit breaker for industrial wiring

type 100af 100 series

with a frame capacity of 100af the 100 series offers two main types the 100eb and .... Bh Type Circuit Breaker For Wiring - By arliselectric - On Wednesday 6 September 2023 8:09 am: circuit breaker

the bh general type offers a versatile range of options to meet various electrical needs with a frame capacity of af it provides fl....

Bh Type Circuit Breaker For Wiring - By arliselectric - On Wednesday 6 September 2023 8:09 am: circuit breaker

the bh general type offers a versatile range of options to meet various electrical needs with a frame capacity of af it provides fl.... Import Export Startup Stories

Import Export Startup Stories

Share Your Story & Get Listed at StartImportExport.com- Sheng Chyean Enterprise Co Ltd: Ming Liu Of Sheng Chyean Enterprise Providing Maintenance Service To Local Wire Drawing Mills From Taiwan

- Al Rahma For Import And Export: Yasser Arfa Of Al Rahma For Import And Export From Egypt

- Shanghai Allstar Industrial Co., Ltd: Tony Tang Of Shanghai Allstar Industrial, A Manufacturer Of Various Cold Roll Forming Machines From China

- Zhejiang Tianfeng Plastic Machinery Plant: Herbert He Of Zhejiang Tianfeng Plastic Machinery Plant, A Manufacturer Of PP Woven Bag Machinery From China

- Guangzhou Hi-Power Machine Co Ltd: Owen Zeng Of Guangzhou Hi-Power Machine, A Surface Preparation Equipment And Industrial Vacuum Cleaners From China

Recycling of metal Classification Navigation

Recycling of metal Classification Navigation

Main - Industrial Cleaning Services - Refuse disposal and treatment - Recycling services - Recycling of metal [18]

TradersCity.com shall not be held liable for any user posted/submitted content including but not limited to trade leads, profiles, images, and any other data. TradersCity.com does not and did not verify any of users posted/submitted data nor is implicitly or explicitly recommending these business offers. TradersCity does not verify truthfulness, accuracy, completeness, nor legality of any businesses, services, and leads posted here. TradersCity does not represent Sellers or Buyers in any transaction between users of the website and is unable to make any opinion in regard to their performance in any transaction. TradersCity neither guarantees nor undertakes in any dispute between sellers and buyers. Protect your business from fraud by trading safely