A free import export trade leads B2B marketplace since 1996 for manufacturers, suppliers, exporters, importers, buyers, sellers, wholesalers, freight forwarders, shippers, trade shows, exhibits, and export management.

Hello visitor from USA - 56 visiting from

USA - 56 visiting from  26 USA

26 USA  15 Canada

15 Canada  5 France

5 France  3 UK

3 UK  2 Belgium

2 Belgium  1 Singapore

1 Singapore  1 Brazil

1 Brazil  1 Ukraine

1 Ukraine  1 Liechtenstein

1 Liechtenstein  1 Australia

1 Australia

Hello visitor from

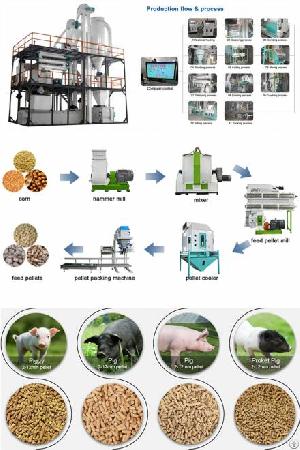

Pig Feed Pellets Production Process

Posted at: Offers to Sell and Export | Posted on: Friday 4 June 2021 8:38 am | Poster last visit: Thursday 28 October 2021 | Targeted Countries: Nigeria | Saudi Arabia | Botswana

Product Category: Main

» Live Plant and Animal Material and Accessories and Supplies

» Animal feed

» Livestock feed

» Feed alfalfa or lucerne meal or pellets

» Pig Feed Pellets Production Process

Product Description:

Pig in different growth stage has different requirements, so small pellets for piglets and big pellets

for big pigs as to pig feeding pellet size. Fusmar poultry feed pellet making machine can make high-quality pig feed pellets.

Raw Materials Crushing

Raw materials need to be crushed first before pelletizing. As to the materials grinding, you can weigh the raw materials according to the formula and then ground them in feed hammer mill, or you can ground them separately and then mix. These two methods are both OK and you can choose according to your self condition. The fineness of raw materials have a significant effect on feed use efficiency. The smaller the size of ground raw materials, the easier the gelatinization of materials, thus easier pellets to be formed. For pig feed pellets making, the screen sieve diameter of feed hammer mill is less than 1mm, while for weaned piglet is only 0.3mm.

Raw Materials Mixing

Mixing is an essential operation for the whole pig feed pellets production line. Grounded raw materials should mix evenly before sent to be pressed.

Pig Feed Pellets Pressing

Pressing is the core process for pig pellets producing. Ring die feed pellet mill is the indispensable equipment in this process. Moisture content, temperature, and steam pressure during this process have a great influence on the quality of the final pellets. Pellet’s hardness will increase if the moisture content of raw materials is higher than 8-10%. The most suitable moisture content is 16-17%.

Temperature requirement is not higher than 88% which can range from 82℃ to 88℃ according to the pellet formation status and moisture content of the pellets. If the pelletizing temperature is low, the starch gelatinization is not sufficient, then pelletizing effect is lower; however, if the temperature is too high, the nutrient will lose seriously.

Pig Feed Pellets Cooling And Packing

Pig feed pellets are soft and hot after processed by ring die feed pellet mill, so transfer them into the feed cooling machine to remove heat and moisture contained in the pellets becomes necessary. After cooling, pellets are dry and hard, they can be transported to the packing machine to be packed in bags, which then becomes convenient for storage and transportation.

Global Pig Market

Pork is the world’s most consumed meat from terrestrial animals. Demand for pork has been rising in recent decades. The reasons for this can be the changes in consumption patterns as a result of an income increase in the middle-class with fast-growing economies. Pig sector is the fastest-growing livestock subsector for its increasing consumption demand. There were more than one million pigs killed each year worldwide. Pig breeding technologies have also made a few improvements, such as pig feed pellets, to turn pig production into a high-input, high-output industry.

Why Choose Pig Feed Pellets

Pellet feed first appeared in Europe, and account for most of today’s feed market in America, Japan, Germany, etc. The average level of the world’s feed pellets using is about 60%. Then why choose feed pellets for breeding? Generally speaking, there are two types of pig feed: powdery feed and pellets feed. Powdery feed has two major feeding methods: dry feeding and wet feeding. Wet feeding is mixing the feed with water, which is not suitable for scientific feeding because of the reduction of food intake. As to dry feeding, if the powder is fine, it would affect pig food intake to some extent, while if the powder is coarse, pig food utilization rate may be influenced. Pellet feed has some superior advantages for pig breeding compared with powdery feed.

Advantages Of Pig Feed Pellets

1.Disinfection and sterilization. During the pelletizing process, toxic substances or inhibiting factors are damaged due to the 100 ~ 120℃ hot steam. So pellets are more healthy for pigs.

2.Reduce waste and improve feed palatability. Feed pellets have large density and high nutrition concentration, which can improve the palatability and digestibility of pig feed. Moreover, feed pellet has uniform size and pelleted type, which avoids pigs from choosing what they like to eat.

3.Convenient for storing and transport. The volume of feed particles reduced about 1/3 than powder, together with its high density makes pellets easy to store and transport. Unlike powdery feed which is easy to absorb moisture and then become moldy, pig feed pellets scattered well and have high storage stability.

Pig feed pellet production line is generally consisted of feed hammer mill, dryer, mixer, feed pellet mill, cooler, packing scales. Tell us your raw material, requirements of capacity and budget for the plant. Fusmar Machinery can design a suitable and specific solution for you.

Company Contact:

Contact Name: Amy Yan

Company Name: Zhengzhou Fusmar Machinery Co., Ltd

Email:

Tel: +8615838279423

Fax: +8615838279423

Street Address: No.45 Agricultural

Road, Jinshui District Zhengzhou,

Henan 450003 China

Other Contact Info:

Skype:

Website: https://www.feedpelletmills.com

Member name: FusmarMachinery

Country: China

China

Member Since: 28 May 2019

Total Leads: 216 FusmarMachinery Import Export Business Leads

Business focus: Pellet Mill, Fish Feed Machine, Charcoal Briquette Machine

Chat:

Verify: Safe Import Export Tips

for big pigs as to pig feeding pellet size. Fusmar poultry feed pellet making machine can make high-quality pig feed pellets.

Raw Materials Crushing

Raw materials need to be crushed first before pelletizing. As to the materials grinding, you can weigh the raw materials according to the formula and then ground them in feed hammer mill, or you can ground them separately and then mix. These two methods are both OK and you can choose according to your self condition. The fineness of raw materials have a significant effect on feed use efficiency. The smaller the size of ground raw materials, the easier the gelatinization of materials, thus easier pellets to be formed. For pig feed pellets making, the screen sieve diameter of feed hammer mill is less than 1mm, while for weaned piglet is only 0.3mm.

Raw Materials Mixing

Mixing is an essential operation for the whole pig feed pellets production line. Grounded raw materials should mix evenly before sent to be pressed.

Pig Feed Pellets Pressing

Pressing is the core process for pig pellets producing. Ring die feed pellet mill is the indispensable equipment in this process. Moisture content, temperature, and steam pressure during this process have a great influence on the quality of the final pellets. Pellet’s hardness will increase if the moisture content of raw materials is higher than 8-10%. The most suitable moisture content is 16-17%.

Temperature requirement is not higher than 88% which can range from 82℃ to 88℃ according to the pellet formation status and moisture content of the pellets. If the pelletizing temperature is low, the starch gelatinization is not sufficient, then pelletizing effect is lower; however, if the temperature is too high, the nutrient will lose seriously.

Pig Feed Pellets Cooling And Packing

Pig feed pellets are soft and hot after processed by ring die feed pellet mill, so transfer them into the feed cooling machine to remove heat and moisture contained in the pellets becomes necessary. After cooling, pellets are dry and hard, they can be transported to the packing machine to be packed in bags, which then becomes convenient for storage and transportation.

Global Pig Market

Pork is the world’s most consumed meat from terrestrial animals. Demand for pork has been rising in recent decades. The reasons for this can be the changes in consumption patterns as a result of an income increase in the middle-class with fast-growing economies. Pig sector is the fastest-growing livestock subsector for its increasing consumption demand. There were more than one million pigs killed each year worldwide. Pig breeding technologies have also made a few improvements, such as pig feed pellets, to turn pig production into a high-input, high-output industry.

Why Choose Pig Feed Pellets

Pellet feed first appeared in Europe, and account for most of today’s feed market in America, Japan, Germany, etc. The average level of the world’s feed pellets using is about 60%. Then why choose feed pellets for breeding? Generally speaking, there are two types of pig feed: powdery feed and pellets feed. Powdery feed has two major feeding methods: dry feeding and wet feeding. Wet feeding is mixing the feed with water, which is not suitable for scientific feeding because of the reduction of food intake. As to dry feeding, if the powder is fine, it would affect pig food intake to some extent, while if the powder is coarse, pig food utilization rate may be influenced. Pellet feed has some superior advantages for pig breeding compared with powdery feed.

Advantages Of Pig Feed Pellets

1.Disinfection and sterilization. During the pelletizing process, toxic substances or inhibiting factors are damaged due to the 100 ~ 120℃ hot steam. So pellets are more healthy for pigs.

2.Reduce waste and improve feed palatability. Feed pellets have large density and high nutrition concentration, which can improve the palatability and digestibility of pig feed. Moreover, feed pellet has uniform size and pelleted type, which avoids pigs from choosing what they like to eat.

3.Convenient for storing and transport. The volume of feed particles reduced about 1/3 than powder, together with its high density makes pellets easy to store and transport. Unlike powdery feed which is easy to absorb moisture and then become moldy, pig feed pellets scattered well and have high storage stability.

Pig feed pellet production line is generally consisted of feed hammer mill, dryer, mixer, feed pellet mill, cooler, packing scales. Tell us your raw material, requirements of capacity and budget for the plant. Fusmar Machinery can design a suitable and specific solution for you.

Company Contact:

Contact Name: Amy Yan

Company Name: Zhengzhou Fusmar Machinery Co., Ltd

Email:

Tel: +8615838279423

Fax: +8615838279423

Street Address: No.45 Agricultural

Road, Jinshui District Zhengzhou,

Henan 450003 China

Other Contact Info:

Skype:

Website: https://www.feedpelletmills.com

Member name: FusmarMachinery

Country:

Member Since: 28 May 2019

Total Leads: 216 FusmarMachinery Import Export Business Leads

Business focus: Pellet Mill, Fish Feed Machine, Charcoal Briquette Machine

Chat:

Verify: Safe Import Export Tips

Similar Suppliers And Manufacturers Import Export Trade Leads

Similar Suppliers And Manufacturers Import Export Trade Leads

F-81395 T3ar Feed Pig Extruder Roller Bearing - By lyjhbearing - On Sunday 5 February 2023 10:42 am: pig extruder roller bearing

f-81395 t3ar f-81395 t3ar bearings specification as following

bearing old bearing code rows no dimensions load rating....

F-81395 T3ar Feed Pig Extruder Roller Bearing - By lyjhbearing - On Sunday 5 February 2023 10:42 am: pig extruder roller bearing

f-81395 t3ar f-81395 t3ar bearings specification as following

bearing old bearing code rows no dimensions load rating.... Feed Pig Extruder Axial Roller Bearing F-51909 T3ar - By jinshuobearing - On Monday 3 July 2023 1:50 am: pig extruder axial roller bearing f-51909 t3ar

our products have been widely used in the fields of engineering machinery industrial pumps machine ....

Feed Pig Extruder Axial Roller Bearing F-51909 T3ar - By jinshuobearing - On Monday 3 July 2023 1:50 am: pig extruder axial roller bearing f-51909 t3ar

our products have been widely used in the fields of engineering machinery industrial pumps machine .... Tamdem Roller Bearing F-53871 T4ar For Feed Pig Extruder - By jinshuobearing - On Wednesday 28 June 2023 1:24 am: pig extruder

bearing factory model f-53871 t4ar

china bearing old type f-53871 t4ar

bearing boundary dimension 35x80x90mm

id inner diameter 35 ....

Tamdem Roller Bearing F-53871 T4ar For Feed Pig Extruder - By jinshuobearing - On Wednesday 28 June 2023 1:24 am: pig extruder

bearing factory model f-53871 t4ar

china bearing old type f-53871 t4ar

bearing boundary dimension 35x80x90mm

id inner diameter 35 .... Tamdem Roller Bearing F-52523-100.t6ar For Feed Pig Extruder - By jinshuobearing - On Sunday 25 June 2023 2:59 am: pig extruder

tandem bearings have the following characteristics

the tandem thrust cylindrical roller bearing provided by luoyang jinshuo precision ....

Tamdem Roller Bearing F-52523-100.t6ar For Feed Pig Extruder - By jinshuobearing - On Sunday 25 June 2023 2:59 am: pig extruder

tandem bearings have the following characteristics

the tandem thrust cylindrical roller bearing provided by luoyang jinshuo precision .... Multi-stage Tandem Roller Bearing F-213625 T6ar For Feed Pig Extrusion - By lyjhbearing - On Sunday 5 February 2023 10:07 am: pig extrusion

f-213625 t6ar f-213625 t6ar bearings specification as following

bearing old bearing code rows no dimensions load rating kn weig....

Multi-stage Tandem Roller Bearing F-213625 T6ar For Feed Pig Extrusion - By lyjhbearing - On Sunday 5 February 2023 10:07 am: pig extrusion

f-213625 t6ar f-213625 t6ar bearings specification as following

bearing old bearing code rows no dimensions load rating kn weig.... Apoaqua Sludge Dewatering Machine For Pig Farm - By Apoaqua - On Friday 12 July 2024 7:04 am: pig manure sludge dewatering screw press for sale

in the livestock industry manure wastewater is a vexing problem apoaqua s dewatering screw press....

Apoaqua Sludge Dewatering Machine For Pig Farm - By Apoaqua - On Friday 12 July 2024 7:04 am: pig manure sludge dewatering screw press for sale

in the livestock industry manure wastewater is a vexing problem apoaqua s dewatering screw press.... Pto Shaft For Feed Mixers - By ptoshaft - On Tuesday 9 May 2023 9:54 am: feed mixer

mainshaft cvo constant velocity

category series tractor

shear bolt yokes

part number model diameter no of splines c-to-bolt bolt c-e....

Pto Shaft For Feed Mixers - By ptoshaft - On Tuesday 9 May 2023 9:54 am: feed mixer

mainshaft cvo constant velocity

category series tractor

shear bolt yokes

part number model diameter no of splines c-to-bolt bolt c-e.... Dg Series Filter Press Feed Pump - By sgbslurrypump - On Monday 25 September 2023 3:06 am: feed pump

product description

- single stage single suction horizontal centrifugal pump

- wet parts such as casing impeller liner plate in anti....

Dg Series Filter Press Feed Pump - By sgbslurrypump - On Monday 25 September 2023 3:06 am: feed pump

product description

- single stage single suction horizontal centrifugal pump

- wet parts such as casing impeller liner plate in anti.... Import Export Startup Stories

Import Export Startup Stories

Share Your Story & Get Listed at StartImportExport.com- Jinan Darin Machinery Co Ltd: Chill Zhang Of Jinan Darin Machinery, A Food Machinery Manufacturer From China

- East International Toys Co Ltd: Bao shujian Of East International Toys Company, A Toys Manufacturer From China

- Shanghai Allstar Industrial Co., Ltd: Tony Tang Of Shanghai Allstar Industrial, A Manufacturer Of Various Cold Roll Forming Machines From China

- Shanghai MTC Industrial Co Ltd: Tony Tang Of Shanghai MTC Industrial Designing And Manufacturing Cold Roll Forming Machines From China

Feed alfalfa or lucerne meal or pellets Classification Navigation

Feed alfalfa or lucerne meal or pellets Classification Navigation

Main - Live Plant and Animal Material and Accessories and Supplies - Animal feed - Livestock feed - Feed alfalfa or lucerne meal or pellets [53]

TradersCity.com shall not be held liable for any user posted/submitted content including but not limited to trade leads, profiles, images, and any other data. TradersCity.com does not and did not verify any of users posted/submitted data nor is implicitly or explicitly recommending these business offers. TradersCity does not verify truthfulness, accuracy, completeness, nor legality of any businesses, services, and leads posted here. TradersCity does not represent Sellers or Buyers in any transaction between users of the website and is unable to make any opinion in regard to their performance in any transaction. TradersCity neither guarantees nor undertakes in any dispute between sellers and buyers. Protect your business from fraud by trading safely