A free import export trade leads B2B marketplace since 1996 for manufacturers, suppliers, exporters, importers, buyers, sellers, wholesalers, freight forwarders, shippers, trade shows, exhibits, and export management.

Hello visitor from USA - 47 visiting from

USA - 47 visiting from  23 USA

23 USA  14 Canada

14 Canada  4 France

4 France  1 Zimbabwe

1 Zimbabwe  1 India

1 India  1 Ireland

1 Ireland  1 Singapore

1 Singapore  1 Brazil

1 Brazil  1 UK

1 UK

Hello visitor from

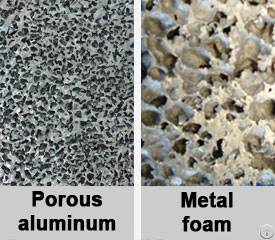

Porous Aluminum Vs Metal Foam

Posted at: Offers to Sell and Export | Posted on: Wednesday 19 December 2012 3:14 pm | Poster last visit: Friday 10 May 2019 |

Product Description:

Metal foam and porous aluminum are both permeable for gaseous and liquid media but have different manufacturing

technologies and therefore different properties.

Aluminum is casted together with crystal salt into the desired shape before the salt is washed out. The salt grains and their contact points are thus replaced by pores. This is how porous aluminium is produced.

Thanks to the high strength and low weight, foamed metals are gaining importance as industrial material. Because of the large internal surface area and good thermal conductivity, foamed metals are used in the automative industry and heat engineering.

Metal foams are usually made of aluminum or aluminum alloys, although it is possible to foam copper, zinc or lead.

We know of two manufacturing technologies for metal foams:

Metal powder or metal chip is mixed with titanium hydride or other explosiv agents and heated above the melting point of the metal, thereby releasing gaseous hydrogen so that the mixture foams.

Gas is injected into the molten metal, after cooling the porous structure remains.

The main difficulties in the production of metal foams are finding the right combination of metal and explosiv agent and heating them up in the right time to the correct temperature, as this is the only way of obtaining the desired result. In doing so, it is practically unpredictable how porosity, pore size and distribution of pores will be.

For these reasons, porous aluminum, with its simple manufacturing technology, is the valuable alternative. The broad range of precisely defined filter grades / cell sizes from 5µm to 200µm can differentiate the application accurately. The extra strong cast interface between porous and non-porous parts opens up a wide range of different applications.

POROUS ALUMINUM vs. METAL FOAM

Broad range of precisely defined filter grades / cell sizes from 5µm to 200µm

Extra strong cast interface between porous and non-porous parts

Extrem strength thanks to cast structure

Simple post-processing (e.g. threading)

Cost-effective manufacturing technology

Company Contact:

Contact Name: Olga Muehldorfer

Company Name: Exxentis

Email:

Tel: +41564300300

Fax:

Street Address: Schartenfelsstrasse

6

Wettingen 5430

Switzerland

Website: https://www.exxentis.co.uk

Member name: Exxentis

Country: Switzerland

Switzerland

Member Since: 19 December 2012

Total Leads: 4 Exxentis Import Export Business Leads

Business focus: Porous Aluminum, Filter, Silencers, Heat Exchangers, Pneumatic Silencers

Chat:

Verify: Safe Import Export Tips

technologies and therefore different properties.

Aluminum is casted together with crystal salt into the desired shape before the salt is washed out. The salt grains and their contact points are thus replaced by pores. This is how porous aluminium is produced.

Thanks to the high strength and low weight, foamed metals are gaining importance as industrial material. Because of the large internal surface area and good thermal conductivity, foamed metals are used in the automative industry and heat engineering.

Metal foams are usually made of aluminum or aluminum alloys, although it is possible to foam copper, zinc or lead.

We know of two manufacturing technologies for metal foams:

Metal powder or metal chip is mixed with titanium hydride or other explosiv agents and heated above the melting point of the metal, thereby releasing gaseous hydrogen so that the mixture foams.

Gas is injected into the molten metal, after cooling the porous structure remains.

The main difficulties in the production of metal foams are finding the right combination of metal and explosiv agent and heating them up in the right time to the correct temperature, as this is the only way of obtaining the desired result. In doing so, it is practically unpredictable how porosity, pore size and distribution of pores will be.

For these reasons, porous aluminum, with its simple manufacturing technology, is the valuable alternative. The broad range of precisely defined filter grades / cell sizes from 5µm to 200µm can differentiate the application accurately. The extra strong cast interface between porous and non-porous parts opens up a wide range of different applications.

POROUS ALUMINUM vs. METAL FOAM

Broad range of precisely defined filter grades / cell sizes from 5µm to 200µm

Extra strong cast interface between porous and non-porous parts

Extrem strength thanks to cast structure

Simple post-processing (e.g. threading)

Cost-effective manufacturing technology

Company Contact:

Contact Name: Olga Muehldorfer

Company Name: Exxentis

Email:

Tel: +41564300300

Fax:

Street Address: Schartenfelsstrasse

6

Wettingen 5430

Switzerland

Website: https://www.exxentis.co.uk

Member name: Exxentis

Country:

Member Since: 19 December 2012

Total Leads: 4 Exxentis Import Export Business Leads

Business focus: Porous Aluminum, Filter, Silencers, Heat Exchangers, Pneumatic Silencers

Chat:

Verify: Safe Import Export Tips

Similar Suppliers And Manufacturers Import Export Trade Leads

Similar Suppliers And Manufacturers Import Export Trade Leads

Sintered Porous Metal Filters For Industry - By YUBOFiltrationEquipment - On Tuesday 16 August 2022 8:30 am: porous metal filters are manufactured from isostatic cool pressing and high-temperature vacuum sintering the micron rating and distribution of the po....

Sintered Porous Metal Filters For Industry - By YUBOFiltrationEquipment - On Tuesday 16 August 2022 8:30 am: porous metal filters are manufactured from isostatic cool pressing and high-temperature vacuum sintering the micron rating and distribution of the po.... Pu Foam For Aluminum Alloy And Plastic Plate - By raywincoating - On Friday 27 October 2023 2:58 am: aluminum alloy and plastic plate

product description

pu foam for making fire door and sanwishboard has the characteristics of high bonding strength ....

Pu Foam For Aluminum Alloy And Plastic Plate - By raywincoating - On Friday 27 October 2023 2:58 am: aluminum alloy and plastic plate

product description

pu foam for making fire door and sanwishboard has the characteristics of high bonding strength .... Ptfe Porous Fabric - By bcptfe - On Monday 27 June 2022 1:47 am: porous ptfe fabric ptfe fabric wholesale supplier

product description

our ptfe porous fabric is made of fiberglass fabric impregnated with spei....

Ptfe Porous Fabric - By bcptfe - On Monday 27 June 2022 1:47 am: porous ptfe fabric ptfe fabric wholesale supplier

product description

our ptfe porous fabric is made of fiberglass fabric impregnated with spei.... We Buy Aluminum Scrap, Aluminum Ingots And Residues - By ComtradeRecycling - On Wednesday 20 July 2022 3:53 am: aluminum scrap ingots amp amp residues

aluminium scraps such as wheels taint tabor tense extrusion airplane alloy used beverage cans and any ....

We Buy Aluminum Scrap, Aluminum Ingots And Residues - By ComtradeRecycling - On Wednesday 20 July 2022 3:53 am: aluminum scrap ingots amp amp residues

aluminium scraps such as wheels taint tabor tense extrusion airplane alloy used beverage cans and any .... Sell Triple-offset Multi-layers Metal To Metal Hard Sealing Butterfly Valve - By IndustrialValveChina - On Thursday 5 May 2022 1:23 am: metal to metal hard sealing

size 2 quot -78 quot dn50-1800

pressure ratings pn16 25 40 60 class150-600lbs

end connections double flanged ....

Sell Triple-offset Multi-layers Metal To Metal Hard Sealing Butterfly Valve - By IndustrialValveChina - On Thursday 5 May 2022 1:23 am: metal to metal hard sealing

size 2 quot -78 quot dn50-1800

pressure ratings pn16 25 40 60 class150-600lbs

end connections double flanged .... Good Using Mixer For Foam Concrete - By buybay - On Tuesday 14 June 2022 7:39 am: foamed concrete fast and

evenly disadvantages of double spindle mixer are a more and heavier however longer lifetime

foamed concrete consumes a ....

Good Using Mixer For Foam Concrete - By buybay - On Tuesday 14 June 2022 7:39 am: foamed concrete fast and

evenly disadvantages of double spindle mixer are a more and heavier however longer lifetime

foamed concrete consumes a .... Foam Genertor To Make All Kinds Of Clc - By buybay - On Tuesday 14 June 2022 7:37 am: foam out of foaming agent

2 the foam generator fg-20 is a ready to use foaming system with integrated air compressor no further requirements are n....

Foam Genertor To Make All Kinds Of Clc - By buybay - On Tuesday 14 June 2022 7:37 am: foam out of foaming agent

2 the foam generator fg-20 is a ready to use foaming system with integrated air compressor no further requirements are n.... Foaming Agent To Make Foam Concete - By buybay - On Tuesday 14 June 2022 7:41 am: foaming agent

amp #61557 product variety improved silicone oil resistance frost resistance anti-bacterial properties effective

against mildew ....

Foaming Agent To Make Foam Concete - By buybay - On Tuesday 14 June 2022 7:41 am: foaming agent

amp #61557 product variety improved silicone oil resistance frost resistance anti-bacterial properties effective

against mildew .... Import Export Startup Stories

Import Export Startup Stories

Share Your Story & Get Listed at StartImportExport.com- Shanghai Minjian Aluminum Co Ltd: Don Yang Of Shanghai Minjian Aluminum From China

- Miraclean Technology Co Ltd: Stephen Au Of Miraclean Technology Manufacturer Of Cleanroom Supplies From China

- Keen Sourcing Shanghai Co Ltd : Alina Of Keen Sourcing Helping Overseas Buyers To Source From China

- ALAKS Aluminyum: Ammar Meshhadi Of ALAKS Aluminyum, A leader in aluminum door and window accessories sector From Turkey

- Sudmen Display Products Co Ltd: Charlie Lu Of Sudmen Display Products Specializing In Designing And Manufacturing Various Display Items

TradersCity.com shall not be held liable for any user posted/submitted content including but not limited to trade leads, profiles, images, and any other data. TradersCity.com does not and did not verify any of users posted/submitted data nor is implicitly or explicitly recommending these business offers. TradersCity does not verify truthfulness, accuracy, completeness, nor legality of any businesses, services, and leads posted here. TradersCity does not represent Sellers or Buyers in any transaction between users of the website and is unable to make any opinion in regard to their performance in any transaction. TradersCity neither guarantees nor undertakes in any dispute between sellers and buyers. Protect your business from fraud by trading safely