A free import export trade leads B2B marketplace since 1996 for manufacturers, suppliers, exporters, importers, buyers, sellers, wholesalers, freight forwarders, shippers, trade shows, exhibits, and export management.

Hello visitor from USA - 42 visiting from

USA - 42 visiting from  25 USA

25 USA  11 Canada

11 Canada  2 UK

2 UK  1 Germany

1 Germany  1 Iran

1 Iran  1 Ukraine

1 Ukraine  1 Brazil

1 Brazil

Hello visitor from

Sewage Intermediate Pumping Stations

Posted at: Offers to Sell and Export | Posted on: Wednesday 26 March 2008 12:16 pm | Poster last visit: Monday 7 April 2008 |

Product Category: Main

» Distribution and Conditioning Systems and Equipment and Components

» Industrial pumps and compressors

» Pumps

» Sewage pumps

» Sewage Intermediate Pumping Stations

Product Description:

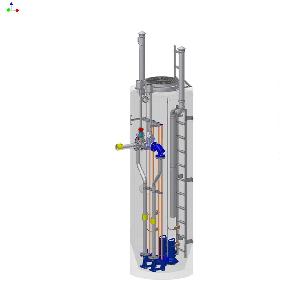

Sewage intermediate pumping stations manufactured by Hydro-Vacuum S.A. are used in gravity-and-pressurized

and pressurized sewerage systems and they are designed to transfer sewage at long distances or to lift them to a high level. Hence pumping stations enable the users located away from the sewage collectors to connect to them.

These users include:

- individual households,

- farms,

- estates of detached houses,

- leisure-and-holiday centres,

- industrial plants,

- municipal and rural sewerage systems.

Thus they can pump sewage, draining and rain water as well as effluent to the cumulative collectors or directly to the sewage treatment plant.

Those pumping stations can be used in sewerage systems as intermediate, area or central pumping stations.

Hydro-Vacuum S.A. sewage intermediate pumping stations are fully automated and do not require constant supervision. A complete sewage pumping station consists of four main sub-assemblies:

- one or two FZ type pumping units,

- a tank,

- UZS type protection-and-control unit,

- hydraulic system.

Sewage intermediate pumping stations are produced with single pumping unit or as multi-pump units. In case of multi-pump units, one pump is always so called active reserve. There are three types of

pumps, depending on the diameter of the pumping connector pipe: FZ1, FZ2, FZ3. Depending on the type of pumped sewage and parameters of operation (Q-H), the are following versions of pumps:

- FZR type, with a shredder,

- FZV type, with free flow (vortex),

- FZB type, with channel impeller,

Pumps equipped with shredders can pump sewage through pipelines of smaller diameters (min. DN 32). Pumps with free flow (vortex) reduce the risk of pump clogging. Pumps with channel impeller are

used mainly to pump rain water, industrial effluent that do not contain long-fibre particles or sewage after pre-separation of solid bodies sewage (pumping station).

Sewage intermediate pumping station are manufactured of four main types of tanks:

- polyethylene PE,

- polymer-concrete,

- concrete B 45,

- polyester reinforced with glass fibre with poured polymer-concrete bottom,

Depending on the designer’s requirements, the above tanks are produced with diameters from 600 to 2500 mm and height up to 6000mm. At the top of the tank there is a manhole that allows the

personnel to go down to the intermediate pumping station or take out the pumps and hydraulic equipment items. Types of manholes are selected depending on the location of the intermediate pumping

station: in or outside the communication passage.

Pumps are controlled using protection-and-control units UZS-4, UZS-7, UZS-8. Those units use float-type level indicators or hydrostatic and ultrasound level control systems. All units are by standard

equipped with acoustic-and-visual signalling of emergency states. Offered GSM monitoring systems are designed to monitor operation of intermediate pumping stations that are located within the reach of

GSM communication.

Internal hydraulic system by standard consists of:

- coupling foots with or without guides – so called top coupling,

- vertical pumping pipes,

- check valves,

- cut-off valves,

- the collector – (dual-pump sewage intermediate pumping stations),

- system rinsing connector.

Pipelines, the collector and fittings are made of acid-resistant steel. Coupling foots and valves are made of cast iron and protected against corrosion using powder paints.

Moreover, intermediate pumping stations are equipped with:

- climb-down ladder,

- access platform (for tanks higher than 5000 mm),

- chains to lower and to lift pumps,

- a chain to mount the level indicator,

- gravity-type venting system.

The above listed parts are made of acid-resistant steel. Venting system is made of PVC.

Main advantages of intermediate sewage pumping station manufactured by Hydro-Vacuum S.A. include:

- modern design solutions,

- complete intermediate pumping station equipment,

- the station can be built quickly and easily on any ground and with any water conditions, with minimum of ground works and fitting operations,

- automated, unattended unit operation,

- pipelines can be flushed through the “fireman’s” tube coupling,

- energy saving, motors available also in an explosion-proof version,

- low purchase and operation costs,

- permanent technical supervision as well as guarantee and post-guarantee technical service,

- easily accessible spare parts,

- intermediate pumping stations can be executed according to individual requirements and adjusted to customer’s needs,

- cheap accessories,

- high efficiency and long life in particularly heavy-duty conditions,

- inflow connector pipe diameter and angle according to customer’s requirements,

- GSM communication with the system,

- guarantee of long-standing, reliable operation.

Company Contact:

Contact Name: Sales

Company Name: Hydro-Vacuum S.A.

Email:

Tel: +48 (56) 45 07 547

Fax: +48 (56) 45 07 346

Street Address: Droga Jeziorna 8

86-303 Grudziądz

Poland

Website: http://www.hydro-vacuum.com.pl

Member name: Hydrovacuumsa

Country: Poland

Poland

Member Since: 25 March 2008

Total Leads: 38 Hydrovacuumsa Import Export Business Leads

Business focus: Pumps, Motors, Protection, Control Systems, Sewage Pumping Stations, Pressure Boosting Systems

Chat:

Verify: Safe Import Export Tips

and pressurized sewerage systems and they are designed to transfer sewage at long distances or to lift them to a high level. Hence pumping stations enable the users located away from the sewage collectors to connect to them.

These users include:

- individual households,

- farms,

- estates of detached houses,

- leisure-and-holiday centres,

- industrial plants,

- municipal and rural sewerage systems.

Thus they can pump sewage, draining and rain water as well as effluent to the cumulative collectors or directly to the sewage treatment plant.

Those pumping stations can be used in sewerage systems as intermediate, area or central pumping stations.

Hydro-Vacuum S.A. sewage intermediate pumping stations are fully automated and do not require constant supervision. A complete sewage pumping station consists of four main sub-assemblies:

- one or two FZ type pumping units,

- a tank,

- UZS type protection-and-control unit,

- hydraulic system.

Sewage intermediate pumping stations are produced with single pumping unit or as multi-pump units. In case of multi-pump units, one pump is always so called active reserve. There are three types of

pumps, depending on the diameter of the pumping connector pipe: FZ1, FZ2, FZ3. Depending on the type of pumped sewage and parameters of operation (Q-H), the are following versions of pumps:

- FZR type, with a shredder,

- FZV type, with free flow (vortex),

- FZB type, with channel impeller,

Pumps equipped with shredders can pump sewage through pipelines of smaller diameters (min. DN 32). Pumps with free flow (vortex) reduce the risk of pump clogging. Pumps with channel impeller are

used mainly to pump rain water, industrial effluent that do not contain long-fibre particles or sewage after pre-separation of solid bodies sewage (pumping station).

Sewage intermediate pumping station are manufactured of four main types of tanks:

- polyethylene PE,

- polymer-concrete,

- concrete B 45,

- polyester reinforced with glass fibre with poured polymer-concrete bottom,

Depending on the designer’s requirements, the above tanks are produced with diameters from 600 to 2500 mm and height up to 6000mm. At the top of the tank there is a manhole that allows the

personnel to go down to the intermediate pumping station or take out the pumps and hydraulic equipment items. Types of manholes are selected depending on the location of the intermediate pumping

station: in or outside the communication passage.

Pumps are controlled using protection-and-control units UZS-4, UZS-7, UZS-8. Those units use float-type level indicators or hydrostatic and ultrasound level control systems. All units are by standard

equipped with acoustic-and-visual signalling of emergency states. Offered GSM monitoring systems are designed to monitor operation of intermediate pumping stations that are located within the reach of

GSM communication.

Internal hydraulic system by standard consists of:

- coupling foots with or without guides – so called top coupling,

- vertical pumping pipes,

- check valves,

- cut-off valves,

- the collector – (dual-pump sewage intermediate pumping stations),

- system rinsing connector.

Pipelines, the collector and fittings are made of acid-resistant steel. Coupling foots and valves are made of cast iron and protected against corrosion using powder paints.

Moreover, intermediate pumping stations are equipped with:

- climb-down ladder,

- access platform (for tanks higher than 5000 mm),

- chains to lower and to lift pumps,

- a chain to mount the level indicator,

- gravity-type venting system.

The above listed parts are made of acid-resistant steel. Venting system is made of PVC.

Main advantages of intermediate sewage pumping station manufactured by Hydro-Vacuum S.A. include:

- modern design solutions,

- complete intermediate pumping station equipment,

- the station can be built quickly and easily on any ground and with any water conditions, with minimum of ground works and fitting operations,

- automated, unattended unit operation,

- pipelines can be flushed through the “fireman’s” tube coupling,

- energy saving, motors available also in an explosion-proof version,

- low purchase and operation costs,

- permanent technical supervision as well as guarantee and post-guarantee technical service,

- easily accessible spare parts,

- intermediate pumping stations can be executed according to individual requirements and adjusted to customer’s needs,

- cheap accessories,

- high efficiency and long life in particularly heavy-duty conditions,

- inflow connector pipe diameter and angle according to customer’s requirements,

- GSM communication with the system,

- guarantee of long-standing, reliable operation.

Company Contact:

Contact Name: Sales

Company Name: Hydro-Vacuum S.A.

Email:

Tel: +48 (56) 45 07 547

Fax: +48 (56) 45 07 346

Street Address: Droga Jeziorna 8

86-303 Grudziądz

Poland

Website: http://www.hydro-vacuum.com.pl

Member name: Hydrovacuumsa

Country:

Member Since: 25 March 2008

Total Leads: 38 Hydrovacuumsa Import Export Business Leads

Business focus: Pumps, Motors, Protection, Control Systems, Sewage Pumping Stations, Pressure Boosting Systems

Chat:

Verify: Safe Import Export Tips

Similar Suppliers And Manufacturers Import Export Trade Leads

Similar Suppliers And Manufacturers Import Export Trade Leads

Api 11 E Conventional Beam Pumping Unit For Oil Sucking Machine - By yppetro - On Friday 14 April 2023 6:32 am: pumping unit for oil sucking machine

product description

beam pumping unit for oil sucking

api c series pumping unit a conventional beam pumping u....

Api 11 E Conventional Beam Pumping Unit For Oil Sucking Machine - By yppetro - On Friday 14 April 2023 6:32 am: pumping unit for oil sucking machine

product description

beam pumping unit for oil sucking

api c series pumping unit a conventional beam pumping u.... Factory Supplier Handcrated Marble Bas Relief Sculpture Of Stations Of The Cross For Church For Sale - By stonekingsculpture - On Monday 8 January 2024 4:33 am: factory supplier handcrated marble bas relief sculpture of stations of the cross for church for sale

this exquisitely hand carved marble low relief sculpture depicts jesus is taken down from the cross and in his mother s arms this bas relief sculpt....

Factory Supplier Handcrated Marble Bas Relief Sculpture Of Stations Of The Cross For Church For Sale - By stonekingsculpture - On Monday 8 January 2024 4:33 am: factory supplier handcrated marble bas relief sculpture of stations of the cross for church for sale

this exquisitely hand carved marble low relief sculpture depicts jesus is taken down from the cross and in his mother s arms this bas relief sculpt.... Submersible Sewage Pump - By sonhopump - On Sunday 2 April 2023 3:56 am: sewage pump series 50hz

1 output 1hp 15hp

2 discharge 2 quot 4 quot inch

3 phase 1 amp #1060 3 amp #1060

4 capacity 0 2 2 5 m3 ....

Submersible Sewage Pump - By sonhopump - On Sunday 2 April 2023 3:56 am: sewage pump series 50hz

1 output 1hp 15hp

2 discharge 2 quot 4 quot inch

3 phase 1 amp #1060 3 amp #1060

4 capacity 0 2 2 5 m3 .... Stainless Steel Sewage Pump - By sonhopump - On Sunday 2 April 2023 3:57 am: sewage pump series 50hz

1 output 0 5kw 15hp

2 discharge 2 quot 4 quot inch

3 phase 1 amp #1060 3 amp #1060

4 capacity 0 1 2 3 m....

Stainless Steel Sewage Pump - By sonhopump - On Sunday 2 April 2023 3:57 am: sewage pump series 50hz

1 output 0 5kw 15hp

2 discharge 2 quot 4 quot inch

3 phase 1 amp #1060 3 amp #1060

4 capacity 0 1 2 3 m.... Gnwq Alloy Cutter Sewage Pump - By kenshinepump - On Thursday 2 March 2023 8:35 am: sewage pump

vortex impeller high chrome alloy cutter 48hr with strong cutting force thermal protection device is built in the sewage submersible....

Gnwq Alloy Cutter Sewage Pump - By kenshinepump - On Thursday 2 March 2023 8:35 am: sewage pump

vortex impeller high chrome alloy cutter 48hr with strong cutting force thermal protection device is built in the sewage submersible.... Ss Parabolic Curved Screen Plate For Sewage Treatment - By YUBOFiltrationEquipment - On Monday 4 July 2022 7:36 am: ss parabolic curved screen plate for sewage treatment

stainless steel wedge wire screen parabolic cureved screen plate for sweage treatment is a screen surface for the arc to open away from wet fine scr....

Ss Parabolic Curved Screen Plate For Sewage Treatment - By YUBOFiltrationEquipment - On Monday 4 July 2022 7:36 am: ss parabolic curved screen plate for sewage treatment

stainless steel wedge wire screen parabolic cureved screen plate for sweage treatment is a screen surface for the arc to open away from wet fine scr.... Trench Grate For Sewage Water - By apple817 - On Thursday 14 June 2007 1:49 am: trench grate for sewage water

we manufacture and export iron casting products the material is gray cast iron and ductile cast iron in more than ten years manufacturing we form o....

Trench Grate For Sewage Water - By apple817 - On Thursday 14 June 2007 1:49 am: trench grate for sewage water

we manufacture and export iron casting products the material is gray cast iron and ductile cast iron in more than ten years manufacturing we form o.... Tsa Sewage Pumping Stations - By Hydrovacuumsa - On Wednesday 26 March 2008 12:06 pm: sewage pumping stations can be used in sewerage and pressurized systems due their advantages they are particularly recommended to be used in

- int....

Tsa Sewage Pumping Stations - By Hydrovacuumsa - On Wednesday 26 March 2008 12:06 pm: sewage pumping stations can be used in sewerage and pressurized systems due their advantages they are particularly recommended to be used in

- int.... Sewage pumps Classification Navigation

Sewage pumps Classification Navigation

Main - Distribution and Conditioning Systems and Equipment and Components - Industrial pumps and compressors - Pumps - Sewage pumps [27]

TradersCity.com shall not be held liable for any user posted/submitted content including but not limited to trade leads, profiles, images, and any other data. TradersCity.com does not and did not verify any of users posted/submitted data nor is implicitly or explicitly recommending these business offers. TradersCity does not verify truthfulness, accuracy, completeness, nor legality of any businesses, services, and leads posted here. TradersCity does not represent Sellers or Buyers in any transaction between users of the website and is unable to make any opinion in regard to their performance in any transaction. TradersCity neither guarantees nor undertakes in any dispute between sellers and buyers. Protect your business from fraud by trading safely