A free import export trade leads B2B marketplace since 1996 for manufacturers, suppliers, exporters, importers, buyers, sellers, wholesalers, freight forwarders, shippers, trade shows, exhibits, and export management.

Hello visitor from USA - 48 visiting from

USA - 48 visiting from  24 USA

24 USA  10 Canada

10 Canada  5 Germany

5 Germany  2 France

2 France  2 Belgium

2 Belgium  2 UK

2 UK  1 Ukraine

1 Ukraine  1 Czech Republic

1 Czech Republic  1 Iran

1 Iran

Hello visitor from

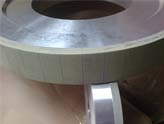

Vitrified Diamond Wheel For Pdc Cutter Rough Grinding, Diamond Grinding Wheel, Cutting

Posted at: Offers to Sell and Export | Posted on: Friday 12 March 2010 1:47 am | Poster last visit: Tuesday 10 August 2010 | Targeted Countries: Germany | India | Turkey

Product Category: Main

» Industrial Manufacturing and Processing Machinery and Accessories

» Lapidary machinery and equipment

» Grinding and sanding and polishing equipment and supplies

» Grinding wheels

» Vitrified Diamond Wheel For Pdc Cutter Rough Grinding, Diamond Grinding Wheel, Cutting

Product Description:

Product Details:

Model Number : KO-20100006

Machine Type :Grinding Machine

Type: Grinding Wheel

Bond:

Vitrfied bond

Grinding type: Surface grinding

Life: 1000 Pcs

Payment& Shipping Terms:

Min Order Quantity: 1 pcs

Price: FOB Beijing $500-$3000

Packaging Details: One wheel, one wooden box

Delivery Time: 15days

Payment Terms: T/T

Supply Ability: 50pcs/pcs per Month

Detailed Product Description:

In this work, a kind of new vitrified bond based on Li2O-Al2O3-SiO2 glass ceramics was used to bond the diamond grains, which is made into grinding wheel and the cylindrical grinding process of polycrystalline diamond compacts (PDCs) by using the new vitrified bond diamond grinding wheel was discussed. Several factors which influence the properties of grinding wheel such as amount of vitrified bond and the kinds and amount of stuff in grinding wheel were also investigated. It was found that the new vitrified bond can firmly combine diamond grains, when there are only diamonds and vitrified bond in the structure of grinding wheel, the longevity of the grinding wheel is about 2.5-3 times as that of resin bond grinding wheel for processing PDCs. The grinding size precision of PDCs can be improved from ±0.03 mm to ±0.01 mm because of larger Young's modulus of vitrified bond than resin bond. The grinding time of a PDC product can be 1.75-2.0 min from 3.25-3.5 min, so this kind of grinding wheel can save much time for processing PDCs. Also, there is hardly noise when using this new vitrified bond diamond grinding wheel to process PDCs. The amount of vitrified bond in grinding wheel influences the longevity of grinding wheel. When the size of diamond grains is 90-107 μm, the optimal amount of vitrified bond in grinding wheel is 21% (wt pet). When the amount of vitrified bond exceeds 21%, there are many pores in grinding block, which will decrease the longevity of grinding wheel. The existence of addition stuff such as Al2O3 or SiC can reduce the longevity of grinding wheel.

Vitrified diamond wheel for rough Grinding the Cylinder of Polycrystalline Diamond Compacts(PDC cutter)

Main technical parameters:

Vitrified diamond wheel for rough Grinding the Cylinder of Polycrystalline Diamond Compacts(PDC cutter)

Specification: grinding 1A1 400×40×203×5

Application: 1308, 0613, 1916 PDC cutters

Processing requirements: finishing allowance≥1.3 mm, taper ≤0.05mm, surface roughness:Ra≤1.6

Life: Grinding more than 1000 pieces PDC

Company Contact:

Contact Name: Anya

Company Name: Henan Shengchuang Super Hard Products Co., Ltd

Email:

Tel: +86-371-67990892

Fax: +86-371-67990893

Street Address: 8625 Room, Radar Elite

Business Center, No. 99 Ruida Rd, New

High-tech Zone, Zhengzhou City,

Henan Province, China 450001

Website: http://www.kosuperhard.com

Member name: kosuperhard

Country: China

China

Member Since: 12 March 2010

Total Leads: 20 kosuperhard Import Export Business Leads

Business focus: Vitrified Diamond Wheel, Diamond Cup Wheel, Rough Grinding Wheel, Pdc Grinding Wheel, Precision Grinding Wheel Diamond Bruting Wheel, Ceramic Diamond

Chat:

Verify: Safe Import Export Tips

Model Number : KO-20100006

Machine Type :Grinding Machine

Type: Grinding Wheel

Bond:

Vitrfied bond

Grinding type: Surface grinding

Life: 1000 Pcs

Payment& Shipping Terms:

Min Order Quantity: 1 pcs

Price: FOB Beijing $500-$3000

Packaging Details: One wheel, one wooden box

Delivery Time: 15days

Payment Terms: T/T

Supply Ability: 50pcs/pcs per Month

Detailed Product Description:

In this work, a kind of new vitrified bond based on Li2O-Al2O3-SiO2 glass ceramics was used to bond the diamond grains, which is made into grinding wheel and the cylindrical grinding process of polycrystalline diamond compacts (PDCs) by using the new vitrified bond diamond grinding wheel was discussed. Several factors which influence the properties of grinding wheel such as amount of vitrified bond and the kinds and amount of stuff in grinding wheel were also investigated. It was found that the new vitrified bond can firmly combine diamond grains, when there are only diamonds and vitrified bond in the structure of grinding wheel, the longevity of the grinding wheel is about 2.5-3 times as that of resin bond grinding wheel for processing PDCs. The grinding size precision of PDCs can be improved from ±0.03 mm to ±0.01 mm because of larger Young's modulus of vitrified bond than resin bond. The grinding time of a PDC product can be 1.75-2.0 min from 3.25-3.5 min, so this kind of grinding wheel can save much time for processing PDCs. Also, there is hardly noise when using this new vitrified bond diamond grinding wheel to process PDCs. The amount of vitrified bond in grinding wheel influences the longevity of grinding wheel. When the size of diamond grains is 90-107 μm, the optimal amount of vitrified bond in grinding wheel is 21% (wt pet). When the amount of vitrified bond exceeds 21%, there are many pores in grinding block, which will decrease the longevity of grinding wheel. The existence of addition stuff such as Al2O3 or SiC can reduce the longevity of grinding wheel.

Vitrified diamond wheel for rough Grinding the Cylinder of Polycrystalline Diamond Compacts(PDC cutter)

Main technical parameters:

Vitrified diamond wheel for rough Grinding the Cylinder of Polycrystalline Diamond Compacts(PDC cutter)

Specification: grinding 1A1 400×40×203×5

Application: 1308, 0613, 1916 PDC cutters

Processing requirements: finishing allowance≥1.3 mm, taper ≤0.05mm, surface roughness:Ra≤1.6

Life: Grinding more than 1000 pieces PDC

Company Contact:

Contact Name: Anya

Company Name: Henan Shengchuang Super Hard Products Co., Ltd

Email:

Tel: +86-371-67990892

Fax: +86-371-67990893

Street Address: 8625 Room, Radar Elite

Business Center, No. 99 Ruida Rd, New

High-tech Zone, Zhengzhou City,

Henan Province, China 450001

Website: http://www.kosuperhard.com

Member name: kosuperhard

Country:

Member Since: 12 March 2010

Total Leads: 20 kosuperhard Import Export Business Leads

Business focus: Vitrified Diamond Wheel, Diamond Cup Wheel, Rough Grinding Wheel, Pdc Grinding Wheel, Precision Grinding Wheel Diamond Bruting Wheel, Ceramic Diamond

Chat:

Verify: Safe Import Export Tips

Similar Suppliers And Manufacturers Import Export Trade Leads

Similar Suppliers And Manufacturers Import Export Trade Leads

Expanded Metal Mesh Used For Cutting And Grinding Discs - By Apankai - On Monday 25 April 2022 2:06 am: grinding dis it secures the safety of discs during cutting and griding it works like the renforcement bars to concrete

materail low carbon steel ....

Expanded Metal Mesh Used For Cutting And Grinding Discs - By Apankai - On Monday 25 April 2022 2:06 am: grinding dis it secures the safety of discs during cutting and griding it works like the renforcement bars to concrete

materail low carbon steel .... Wheel Radio Controlled Grass Cutter Ssw800-150 - By ShandongSupershineRobot - On Friday 14 October 2022 6:24 am: wheel radio controlled grass cutter

specification

model ssw800-150

cutting width 800mm

walking speed 0-6km h

working degree 0-50°

adjustab....

Wheel Radio Controlled Grass Cutter Ssw800-150 - By ShandongSupershineRobot - On Friday 14 October 2022 6:24 am: wheel radio controlled grass cutter

specification

model ssw800-150

cutting width 800mm

walking speed 0-6km h

working degree 0-50°

adjustab.... Four Wheel Gasoline Power Robotic Weed Cutting Machine - By Maxchris - On Thursday 28 July 2022 8:52 am: cutting height

15cm

min cutting height

2cm

power

7 5 hp

place of origin

china

feature

remote control

forward speed

6 km h

power sour....

Four Wheel Gasoline Power Robotic Weed Cutting Machine - By Maxchris - On Thursday 28 July 2022 8:52 am: cutting height

15cm

min cutting height

2cm

power

7 5 hp

place of origin

china

feature

remote control

forward speed

6 km h

power sour.... 4wd Grass Mowers For Agriculture 4 Wheel Gasoline Power Robotic Weed Cutting Machine - By Maxchris - On Thursday 28 July 2022 8:40 am: cutting height

15cm

min cutting height

2cm

power

7 5 hp

place of origin

china

feature

remote control

forward speed

6 km h

power sour....

4wd Grass Mowers For Agriculture 4 Wheel Gasoline Power Robotic Weed Cutting Machine - By Maxchris - On Thursday 28 July 2022 8:40 am: cutting height

15cm

min cutting height

2cm

power

7 5 hp

place of origin

china

feature

remote control

forward speed

6 km h

power sour.... Slope Cutter, China Robotic Slope Mower Price, Remote Brush Cutter For Sale - By ShandongSupershineRobot - On Wednesday 7 December 2022 5:52 am: wheeled wheeled

engine power yamaha 7 5hp loncin 9hp loncin 15hp loncin 7hp loncin 15hp

cutting width 550mm 550mm 800mm 550mm 800mm

adjustable cu....

Slope Cutter, China Robotic Slope Mower Price, Remote Brush Cutter For Sale - By ShandongSupershineRobot - On Wednesday 7 December 2022 5:52 am: wheeled wheeled

engine power yamaha 7 5hp loncin 9hp loncin 15hp loncin 7hp loncin 15hp

cutting width 550mm 550mm 800mm 550mm 800mm

adjustable cu.... Limestone Grinding Mill - By SBM - On Tuesday 6 June 2023 9:39 am: grinding mill is a machine that grinds and powderizes limestone it is very useful in the manufacture of cement glass steel and other industrial pro....

Limestone Grinding Mill - By SBM - On Tuesday 6 June 2023 9:39 am: grinding mill is a machine that grinds and powderizes limestone it is very useful in the manufacture of cement glass steel and other industrial pro.... Inner Race Groove Grinding Machine Qmb125 - By lecn - On Saturday 12 November 2022 3:37 am: grinding machine qmb125

product description

inner race grinding machine with one-time clamping and processing of multiple bj groove 20-65 mm proces....

Inner Race Groove Grinding Machine Qmb125 - By lecn - On Saturday 12 November 2022 3:37 am: grinding machine qmb125

product description

inner race grinding machine with one-time clamping and processing of multiple bj groove 20-65 mm proces.... Cnc Grinding Parts Brake Disc - By Jioutianjing - On Saturday 24 February 2024 7:14 am: grinding parts suppliers focusing on scm440 material our commitment to excellence is reflected in the precision and quality of brake discs crafted t....

Cnc Grinding Parts Brake Disc - By Jioutianjing - On Saturday 24 February 2024 7:14 am: grinding parts suppliers focusing on scm440 material our commitment to excellence is reflected in the precision and quality of brake discs crafted t.... Import Export Startup Stories

Import Export Startup Stories

Share Your Story & Get Listed at StartImportExport.com- Guangdong Shuangling Diamond and Tools Industry Pty Ltd: Grace Of Guangdong Shuangling Diamond and Tools Industry From China

- Diamond Microdermabrasion Machine: Jason Of BP Diamond Microdermabrasion Machine Supplying Beauty Equipment From China

- Ever Tech Laser Technology: Edward Elric Of Ever Tech Laser Technology A Manufacturing Company For Laser Machinery From China

- Qingzhoiu Guohua Construction Machinery Co Ltd: Lucky Wu Of Qingzhoiu Guohua Construction Machinery, A Wheel Loader Manufacturer From China

- Bezel Machinery Shanghai Co Ltd: Gavin Lee Of Bezel Machinery Shanghai From China

Grinding wheels Classification Navigation

Grinding wheels Classification Navigation

Main - Industrial Manufacturing and Processing Machinery and Accessories - Lapidary machinery and equipment - Grinding and sanding and polishing equipment and supplies - Grinding wheels [135]

TradersCity.com shall not be held liable for any user posted/submitted content including but not limited to trade leads, profiles, images, and any other data. TradersCity.com does not and did not verify any of users posted/submitted data nor is implicitly or explicitly recommending these business offers. TradersCity does not verify truthfulness, accuracy, completeness, nor legality of any businesses, services, and leads posted here. TradersCity does not represent Sellers or Buyers in any transaction between users of the website and is unable to make any opinion in regard to their performance in any transaction. TradersCity neither guarantees nor undertakes in any dispute between sellers and buyers. Protect your business from fraud by trading safely