A free import export trade leads B2B marketplace since 1996 for manufacturers, suppliers, exporters, importers, buyers, sellers, wholesalers, freight forwarders, shippers, trade shows, exhibits, and export management.

Hello visitor from USA - 48 visiting from

USA - 48 visiting from  25 USA

25 USA  10 Canada

10 Canada  5 France

5 France  4 UK

4 UK  1 Hong Kong

1 Hong Kong  1 Singapore

1 Singapore  1 Ukraine

1 Ukraine  1 Germany

1 Germany

Hello visitor from

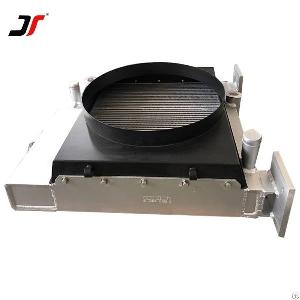

Well-designed Aluminum Air Compressor Aftercooler

Posted at: Offers to Sell and Export | Posted on: Wednesday 13 October 2021 3:34 am | Poster last visit: Friday 11 February 2022 |

Product Category: Main

» Distribution and Conditioning Systems and Equipment and Components

» Industrial pumps and compressors

» Compressor parts or accessories

» Air compressor parts

» Well-designed Aluminum Air Compressor Aftercooler

Product Description:

Product Descriptions

Product name

Well-Designed Aluminum Air Compressor Aftercooler

Application

Air

Compressor Air screw compressor high pressure

Material

Aluminum Alloy 3003, 5A02, 6061

Structure

Plate Fin Heat Exchange core

Model

2bar-40bar (4KW--400KW)

Standard

CE, ISO, ASTM, DIN, etc.

Additional Information

Warranty: 1 Year Lead time: 30 days

Productivity: 150MT/Month Port: Shanghai

Packaging & Delivery: wood case for Various type or customer’ requirements

After-sales Service: 24 hours to service machinery overseas

Customization

1. Heat Transmission

2. Liquid Flow Rate

3. Working Temperature

4. Working Pressure

5. Temperature "In" and "out"

6. Connection Type / Size

7. Painting Requirement

Please kindly provide us your technical parameters, then we can design for you.

Features

1. Combination welded cores-air & oil cores

2. Brazed aluminum core / bar and plate

3. Excellent for field conversions

4. Compact design

5. Light weight

6. Compact, high performance all aluminum core assembly

7. Could be assembled with fan and fan cover

Applications

Highly flexible design options

-Enhanced internal fin geometries for superior cooling

-Wide variety of hot fins to balance internal

Pressure drop

-High efficiency louvered fins for superior

Heat rejection

-Wide variety of debris resistant non-louvered fins

-Specially designed extruded tanks withstand

High pressure

-Ideal for low viscosity fluids

-Welded tanks for a long leak-free life

-Integral bypass relief valves

Our advantage

01 vacuum brazing

1.We haveprofessional qualification certificate of brazing operators.Different products adopt different brazing processes and set corresponding load thermocouples.

2.The surface of the brazing seam is complete, continuous, uniform and smooth.No solder accumulation, overflow, splashing exist.No unmelted or cracks on the surface.

02 argon arc welding

1.We have professional qualification certificate for argon welding operators and Welder Skill Matrix.

2.The crater should be filled up and slightly higher than the base metal.The arc crater must not have cracks and shrinkage holes.Backing plate welding is used for arcstarting and closing.

3.Special processes such as double-sided welding, multi-layer welding, and penetration welding eliminate welding defects and ensure welding quality.

4.The weld surface is straight, beautiful, with uniform scales and uniform height.No surface pores, cracks, obvious bens and serious welds.

5.Develop different standard welding operationconstructions for different products(SOP).

Company Contact:

Contact Name: Harrison

Company Name: Wuxi Jiusheng Heat Exchanger Co., Ltd.

Email:

Tel: +86 18206171482

Fax:

Street Address: Room 2313 No.8

Tianshan Road, High-tech Zone,

Wuxi City, Jiangsu Province 214000

China

Website: https://www.aluminumheatexchanger.com/

Member name: JiushengHeatExchanger

Country: China

China

Member Since: 13 October 2021

Total Leads: 22 JiushengHeatExchanger Import Export Business Leads

Business focus: Automobile Intercooler, Air Compressor, Construction Machinery Hydraulic Oil Cooler, Agricultural Machine Oil Cooler

Chat:

Verify: Safe Import Export Tips

Product name

Well-Designed Aluminum Air Compressor Aftercooler

Application

Air

Compressor Air screw compressor high pressure

Material

Aluminum Alloy 3003, 5A02, 6061

Structure

Plate Fin Heat Exchange core

Model

2bar-40bar (4KW--400KW)

Standard

CE, ISO, ASTM, DIN, etc.

Additional Information

Warranty: 1 Year Lead time: 30 days

Productivity: 150MT/Month Port: Shanghai

Packaging & Delivery: wood case for Various type or customer’ requirements

After-sales Service: 24 hours to service machinery overseas

Customization

1. Heat Transmission

2. Liquid Flow Rate

3. Working Temperature

4. Working Pressure

5. Temperature "In" and "out"

6. Connection Type / Size

7. Painting Requirement

Please kindly provide us your technical parameters, then we can design for you.

Features

1. Combination welded cores-air & oil cores

2. Brazed aluminum core / bar and plate

3. Excellent for field conversions

4. Compact design

5. Light weight

6. Compact, high performance all aluminum core assembly

7. Could be assembled with fan and fan cover

Applications

Highly flexible design options

-Enhanced internal fin geometries for superior cooling

-Wide variety of hot fins to balance internal

Pressure drop

-High efficiency louvered fins for superior

Heat rejection

-Wide variety of debris resistant non-louvered fins

-Specially designed extruded tanks withstand

High pressure

-Ideal for low viscosity fluids

-Welded tanks for a long leak-free life

-Integral bypass relief valves

Our advantage

01 vacuum brazing

1.We haveprofessional qualification certificate of brazing operators.Different products adopt different brazing processes and set corresponding load thermocouples.

2.The surface of the brazing seam is complete, continuous, uniform and smooth.No solder accumulation, overflow, splashing exist.No unmelted or cracks on the surface.

02 argon arc welding

1.We have professional qualification certificate for argon welding operators and Welder Skill Matrix.

2.The crater should be filled up and slightly higher than the base metal.The arc crater must not have cracks and shrinkage holes.Backing plate welding is used for arcstarting and closing.

3.Special processes such as double-sided welding, multi-layer welding, and penetration welding eliminate welding defects and ensure welding quality.

4.The weld surface is straight, beautiful, with uniform scales and uniform height.No surface pores, cracks, obvious bens and serious welds.

5.Develop different standard welding operationconstructions for different products(SOP).

Company Contact:

Contact Name: Harrison

Company Name: Wuxi Jiusheng Heat Exchanger Co., Ltd.

Email:

Tel: +86 18206171482

Fax:

Street Address: Room 2313 No.8

Tianshan Road, High-tech Zone,

Wuxi City, Jiangsu Province 214000

China

Website: https://www.aluminumheatexchanger.com/

Member name: JiushengHeatExchanger

Country:

Member Since: 13 October 2021

Total Leads: 22 JiushengHeatExchanger Import Export Business Leads

Business focus: Automobile Intercooler, Air Compressor, Construction Machinery Hydraulic Oil Cooler, Agricultural Machine Oil Cooler

Chat:

Verify: Safe Import Export Tips

Similar Suppliers And Manufacturers Import Export Trade Leads

Similar Suppliers And Manufacturers Import Export Trade Leads

Air Filter For Air Compressor 39903281 For India Power Plant - By DongfangYoyik - On Monday 17 October 2022 2:19 am: air filter for air compressor 39903281 for india power plant

selection of advanced technology absolutely first-class service quality yoyik over the....

Air Filter For Air Compressor 39903281 For India Power Plant - By DongfangYoyik - On Monday 17 October 2022 2:19 am: air filter for air compressor 39903281 for india power plant

selection of advanced technology absolutely first-class service quality yoyik over the.... 3-in-1 Laser Cutting Air Compressor - By kapacompressor - On Wednesday 31 January 2024 7:24 am: air compressor

integrated easy to install

save the trouble of self equipped with gas storage tank cold dryer and filter for customer

save the t....

3-in-1 Laser Cutting Air Compressor - By kapacompressor - On Wednesday 31 January 2024 7:24 am: air compressor

integrated easy to install

save the trouble of self equipped with gas storage tank cold dryer and filter for customer

save the t.... Low Pressure Air Compressor - By ahaircompressor - On Wednesday 29 March 2023 6:38 am: air compressor

air horse special make in line vector control* and pid control it is realize fast response and ensure safety and reliability

what ....

Low Pressure Air Compressor - By ahaircompressor - On Wednesday 29 March 2023 6:38 am: air compressor

air horse special make in line vector control* and pid control it is realize fast response and ensure safety and reliability

what .... Kszj-18 / 17 Kaishan Air Compressor - By jcdrill - On Tuesday 10 May 2022 3:06 am: air compressor

air end the patented design of rotor profile with large-diameter air end and diesel is directly connected through high-elastic coupl....

Kszj-18 / 17 Kaishan Air Compressor - By jcdrill - On Tuesday 10 May 2022 3:06 am: air compressor

air end the patented design of rotor profile with large-diameter air end and diesel is directly connected through high-elastic coupl.... Tank Mounted Air Compressor - By ahaircompressor - On Wednesday 29 March 2023 6:37 am: air compressor

by ensuring that you achieve the highest productivity in your shop while reducing the total cost of ownership to the absolute lowest l....

Tank Mounted Air Compressor - By ahaircompressor - On Wednesday 29 March 2023 6:37 am: air compressor

by ensuring that you achieve the highest productivity in your shop while reducing the total cost of ownership to the absolute lowest l.... Smart Screw Air Compressor Supplier - By ahaircompressor - On Wednesday 29 March 2023 6:45 am: air compressor supplier

simplified configuration and cabinet size the layout is more concise the overall size is smaller than fixed speed compresso....

Smart Screw Air Compressor Supplier - By ahaircompressor - On Wednesday 29 March 2023 6:45 am: air compressor supplier

simplified configuration and cabinet size the layout is more concise the overall size is smaller than fixed speed compresso.... Permanent Magnet Screw Air Compressor - By kapacompressor - On Wednesday 31 January 2024 7:23 am: air compressor

permanent magnet frequency conversion integrated screw type

compared with the ordinary three-phase asynchronous motor the efficient ....

Permanent Magnet Screw Air Compressor - By kapacompressor - On Wednesday 31 January 2024 7:23 am: air compressor

permanent magnet frequency conversion integrated screw type

compared with the ordinary three-phase asynchronous motor the efficient .... Belt Driven Screw Air Compressor Ce - By ahaircompressor - On Wednesday 29 March 2023 6:45 am: air compressor ce

airhorse was one of the first grade screw compressor manufactures to implement the v-belt drive airhorse screw compressors with v-....

Belt Driven Screw Air Compressor Ce - By ahaircompressor - On Wednesday 29 March 2023 6:45 am: air compressor ce

airhorse was one of the first grade screw compressor manufactures to implement the v-belt drive airhorse screw compressors with v-.... Import Export Startup Stories

Import Export Startup Stories

Share Your Story & Get Listed at StartImportExport.com- Shanghai Minjian Aluminum Co Ltd: Don Yang Of Shanghai Minjian Aluminum From China

- ALAKS Aluminyum: Ammar Meshhadi Of ALAKS Aluminyum, A leader in aluminum door and window accessories sector From Turkey

- Kornik Export Company: Ekambi Pramarasse Of Kornik Export Company From Thailand

- Prelead Industy Co Ltd: Norman Cao Of Prelead Industry, A Trading Company Specializing In Industrial And Electrical Products And Plastic Injection Molding From China

- Guangzhou Kinggreat Trading Ltd: Emma Lee Of Guangzhou Kinggreat Trading An Electronic Products And Accessories Supplier From China

Air compressor parts Classification Navigation

Air compressor parts Classification Navigation

Main - Distribution and Conditioning Systems and Equipment and Components - Industrial pumps and compressors - Compressor parts or accessories - Air compressor parts [35]

TradersCity.com shall not be held liable for any user posted/submitted content including but not limited to trade leads, profiles, images, and any other data. TradersCity.com does not and did not verify any of users posted/submitted data nor is implicitly or explicitly recommending these business offers. TradersCity does not verify truthfulness, accuracy, completeness, nor legality of any businesses, services, and leads posted here. TradersCity does not represent Sellers or Buyers in any transaction between users of the website and is unable to make any opinion in regard to their performance in any transaction. TradersCity neither guarantees nor undertakes in any dispute between sellers and buyers. Protect your business from fraud by trading safely